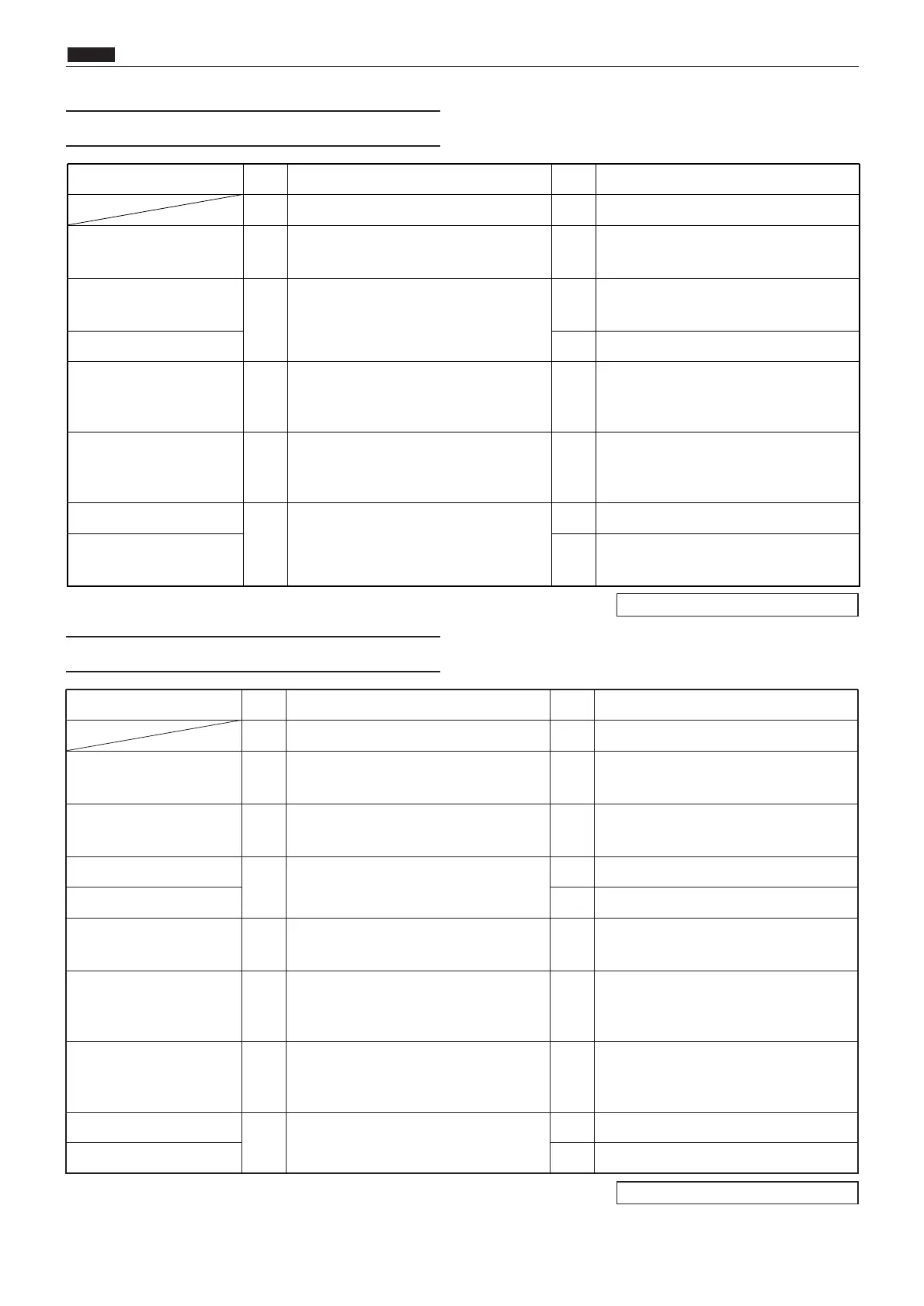

Cause/Detective section

Procedures

Result

CountermeasureItems to be checked

1 Does the cutter operate? No Follow the procedure (4).

HELP setting 2

Does cutter execute reciprocating

motion in each platemaking operation?

No Set [

*

1

**

] with HELP55*.

Master creased

3 Are there creases/sags in master?

Yes

Depress PUSH lever to eliminate

creases.

Cutter sharpness No Replace the cutter unit.

Cutter unit 4

Measure the voltage at the cutter motor

terminals when the cutter is activated.

Is it 23V?

Yes Replace the cutter unit.

Regulated power supply 5

Measure voltage between CN2-1 (+)

and CN2-2 (GND) of the regulated

power supply. Is it +24V?

No Replace the regulated power supply.

Drive PCB unit

6

Does replacing the drive PCB unit solve

the problem?

Yes Finish

Main PCB No

Check the connector and bundled wire.

If OK, replace the main PCB.

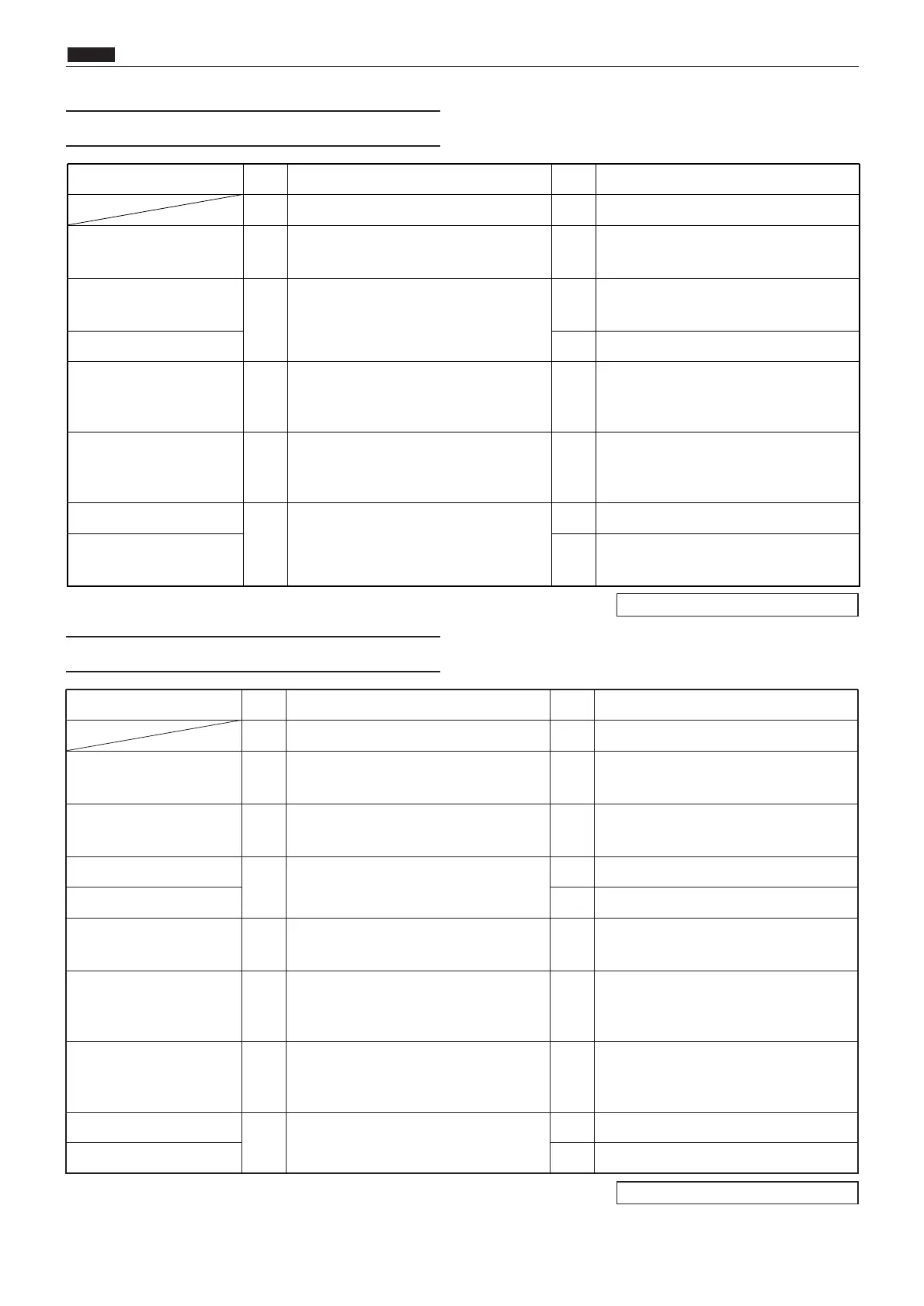

Cause/Detective section

Procedures

Result

CountermeasureItems to be checked

1 Does the drum rotate? No Follow the procedure (5).

Main PCB Unit 2

Check the encoder sensor (PS7) with

the HELP mode (H-06)*. Is it normal?

Yes

Check the encoder sensor position. If it

is OK, replace the main PCB Unit.

Encoder sensor 3

Is the cause cleared by replacing the

encoder?

Yes Finish

Main motor PCB Unit

4

Is the cause cleared by replacing the

main motor PCB Unit?

Yes Finish

Main PCB Unit No Replace the main PCB Unit.

The drum interferes with

the main body.

5

Does the main motor rotate when the

drum is removed?

Yes Remove the interference.

Driving gear is damaged

and there is a foreign

object.

6

Does the main motor rotate when the

driving timing belt is removed?

Yes

Check that the driving gear is damaged

and there is a foreign object. If any,

remove the cause.

Main PCB Unit 7

Does the main motor rotate at the

before-stop speed when the motor PCB

Unit CN3-8 produces a short circuit to

GND?

Yes

Check the bundled wire and connector.

If OK, replace the main PCB Unit.

Main motor PCB Unit

8

Is the cause cleared by replacing the

main motor PCB Unit?

Yes Finish

Main motor No Replace the main motor.

Loading...

Loading...