Tools | Tool compensation

4

Tool radius compensation

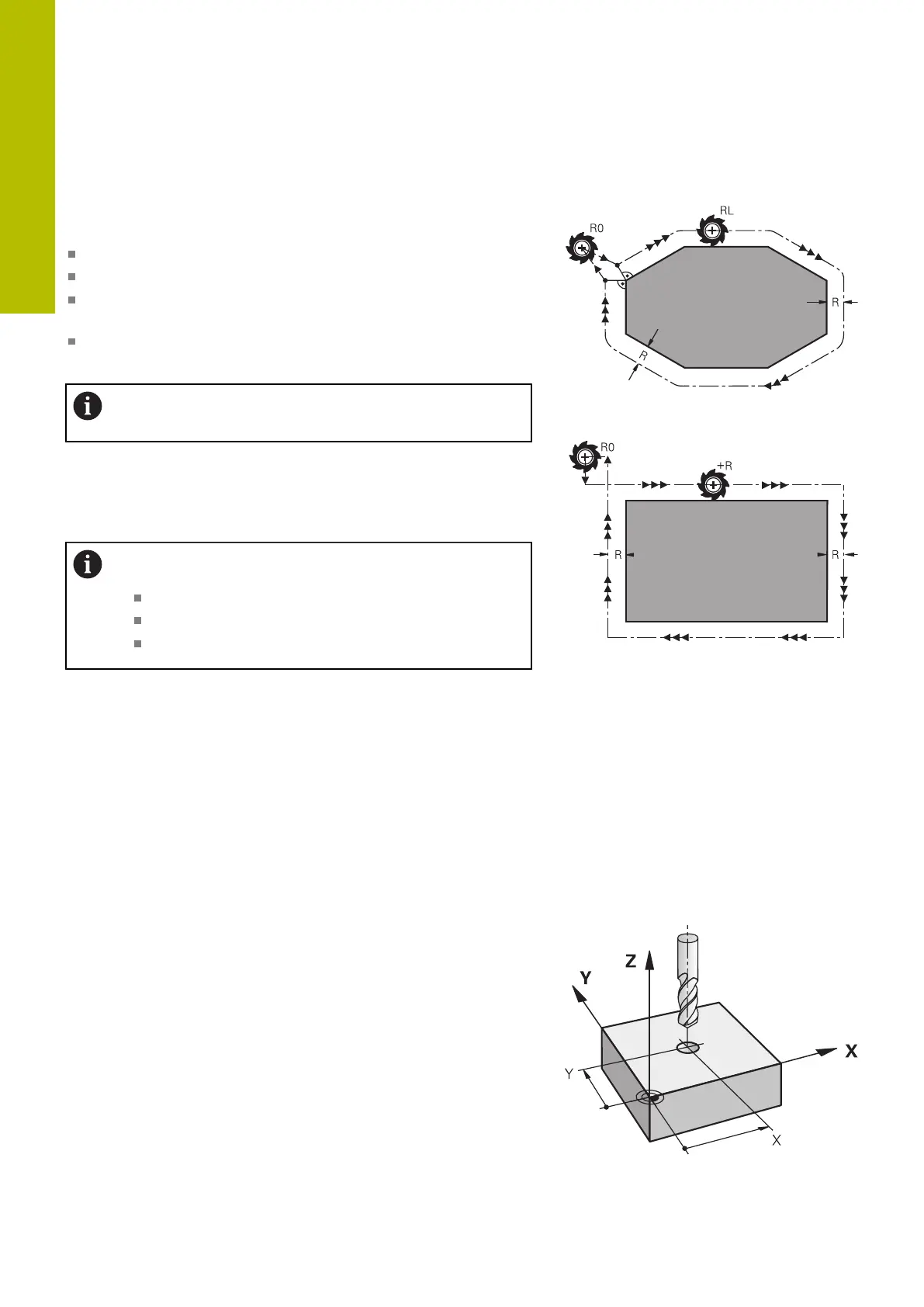

An NC block can contain the following types of tool radius

compensation:

RL or RR for radius compensation of any contouring function

R0, if there is no radius compensation

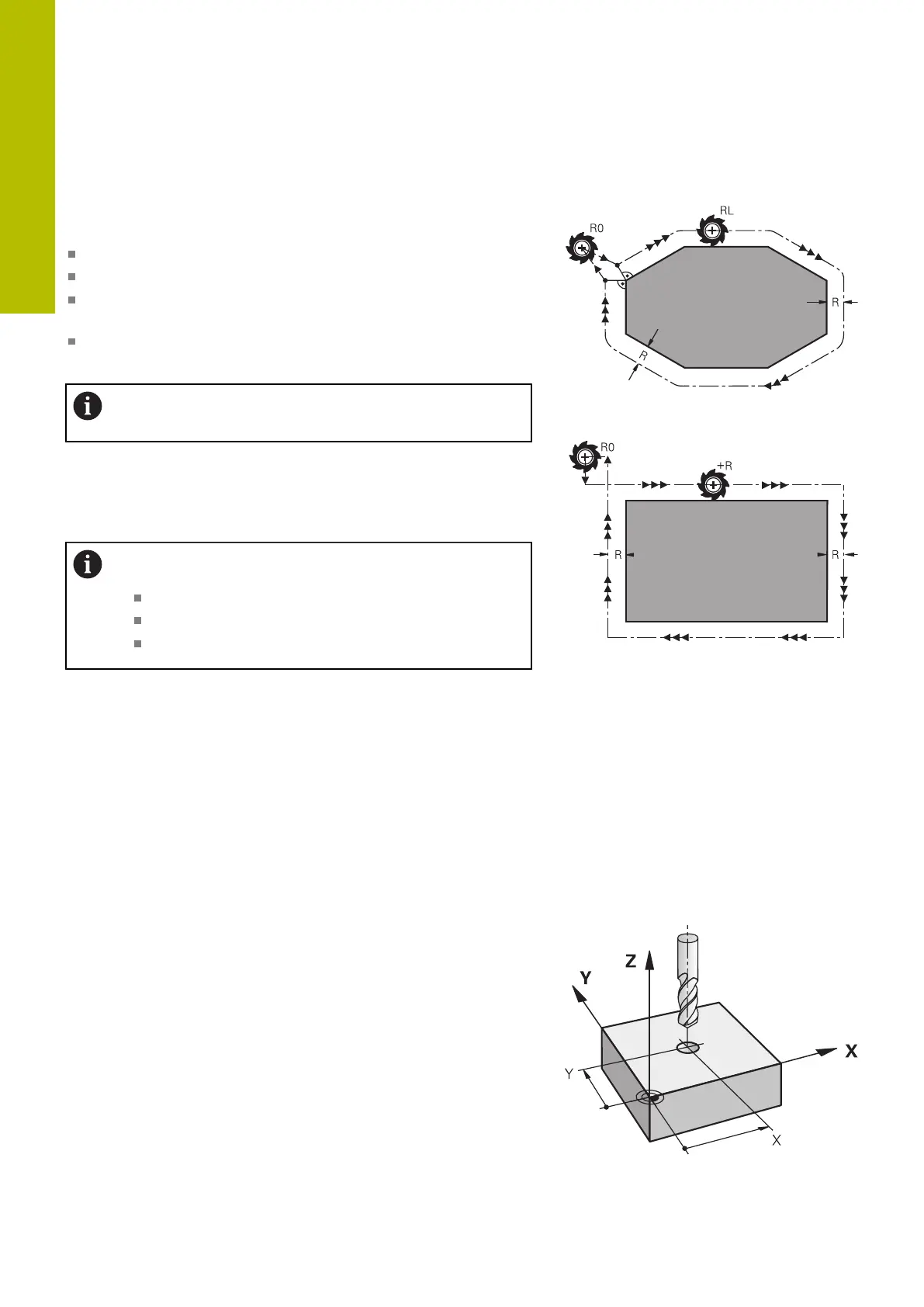

R+ lengthens a paraxial movement by the amount of the tool

radius

R- shortens a paraxial movement by the amount of the tool

radius

The control shows an active tool compensation in the

general status display.

The radius compensation takes effect as soon as a tool is called

and is moved with one of the abovementioned types of tool radius

compensation within a straight-line block or within a paraxial

movement in the working plane.

The control automatically cancels radius compensation

in the following cases:

Straight-line block with R0

DEP function for departing from the contour

Selection of a new NCprogram via PGM MGT

For radius compensation, the control takes the delta values from

both the TOOL CALL block and the tool table into account:

Compensation value = R + DR

TAB

+ DR

Prog

with

R: Tool radius R from TOOL DEF block or tool table

DR

TAB

: Oversize for radius DR in the tool table

DR

Prog

: Oversize DR for radius from TOOL CALL block or

from the compensation table

Further information: "Compensation table",

Page 398

Movements without radius compensation: R0

The tool center moves in the working plane to the programmed

coordinate.

Applications: Drilling and boring, pre-positioning

134

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

Loading...

Loading...