Fundamentals | NC fundamentals

Reference systems

For the control to move an axis in accordance with a defined path, it

requires a reference system.

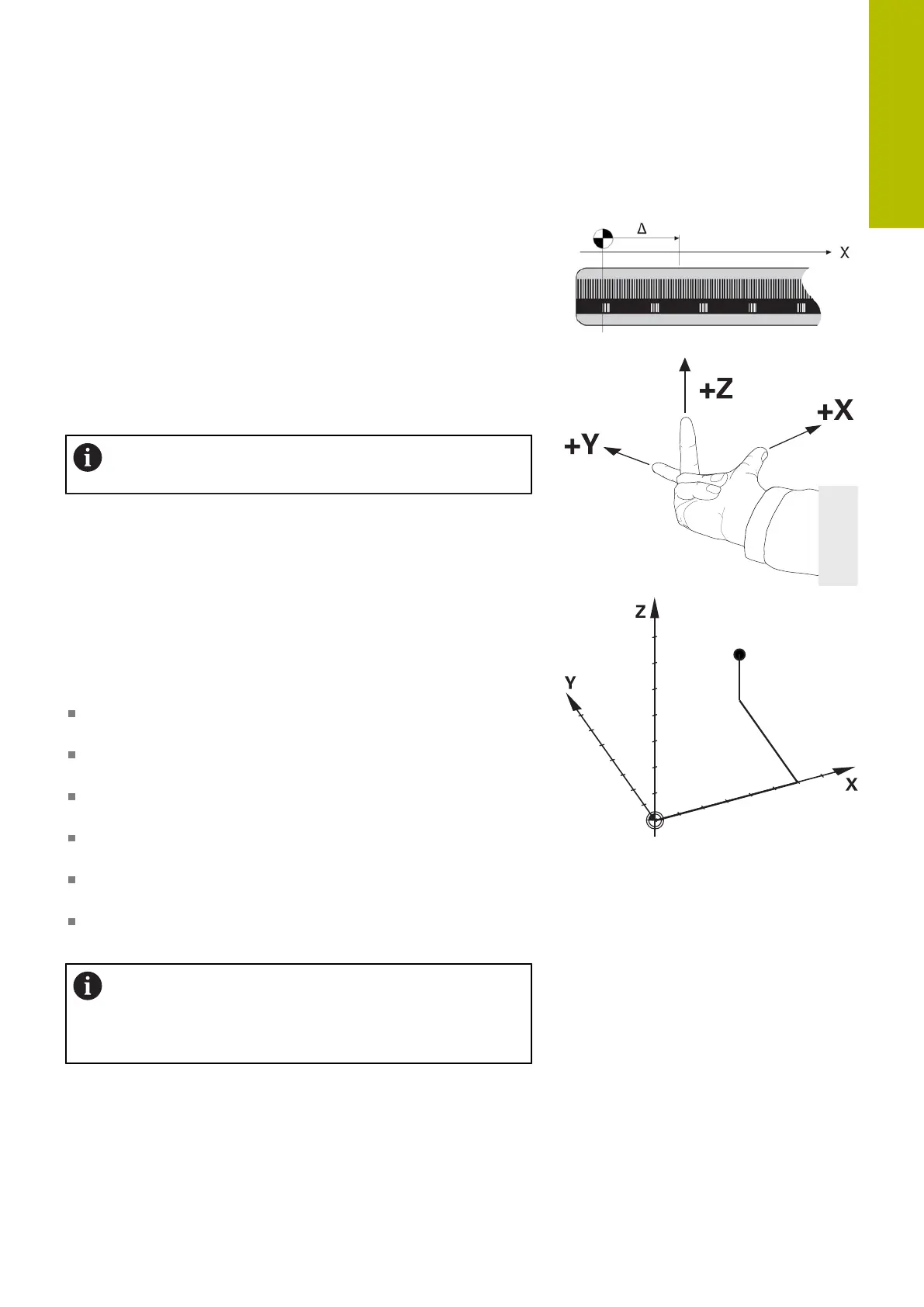

A paraxially mounted linear encoder on a machine tool serves

as a simple reference system for linear axes. The linear encoder

represents a number ray, a one-dimensional coordinate system.

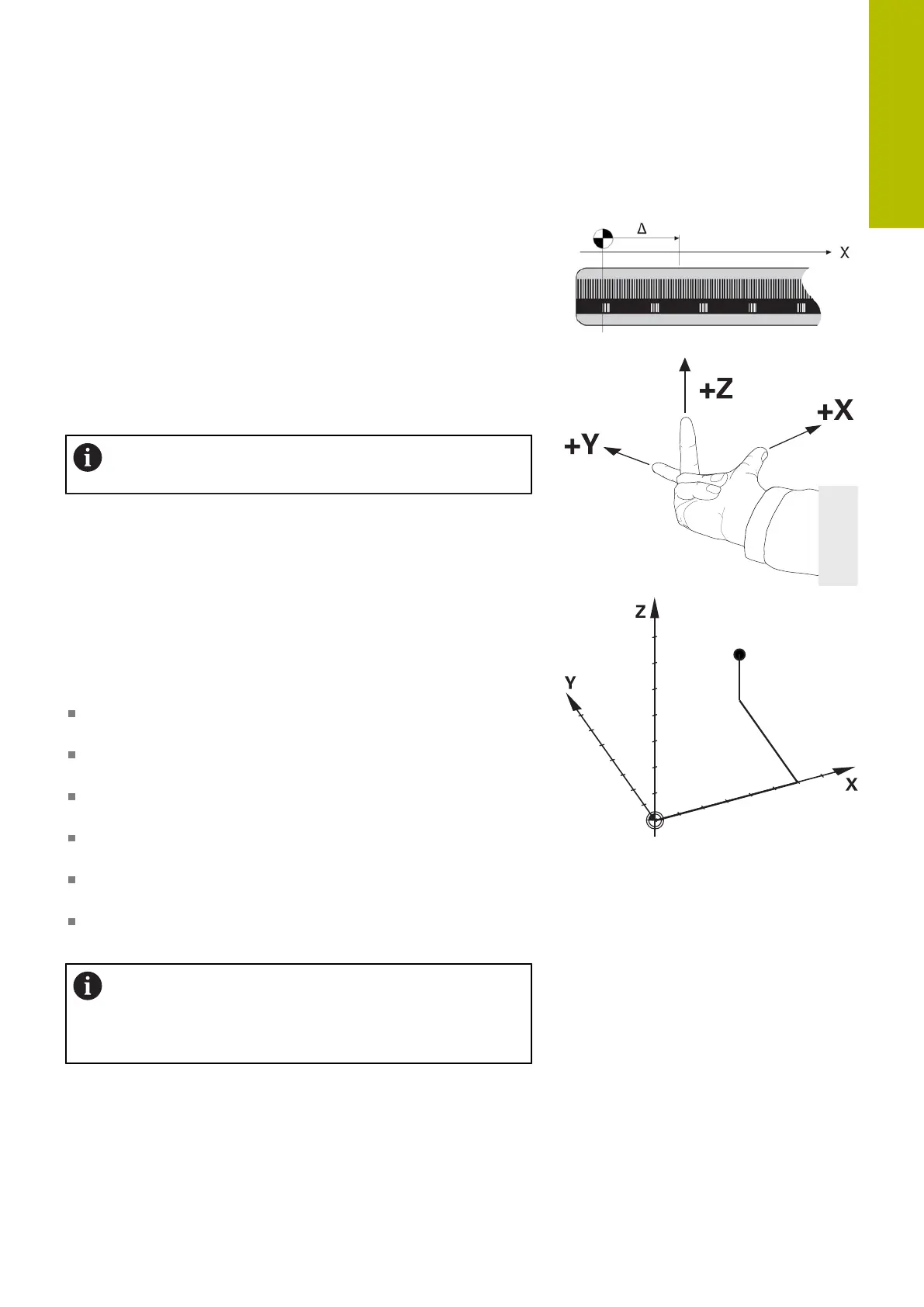

To approach a point on the plane, the control requires two axes and

therefore a reference system with two dimensions.

To approach a point in space, the control requires three axes and

therefore a reference system with three dimensions. If these three

axes are arranged perpendicularly to each other, this creates a

three-dimensional Cartesian coordinate system.

According to the right-hand rule the fingertips point in the

positive directions of the three principal axes.

For a point to be uniquely determined in space, a coordinate origin

is needed in addition to the arrangement of the three dimensions.

The common intersection serves as the coordinate origin in a 3-D

coordinate system. This intersection has the coordinates X+0, Y+0,

and Z+0.

In order, for example, for the control to always perform a tool

change at the same position, as well as always execute a machining

operation referenced to the current workpiece position, the control

must be able to differentiate between different reference systems.

The control differentiates between the following reference systems:

Machine coordinate system M-CS:

Machine Coordinate System

Basic coordinate system B-CS:

Basic Coordinate System

Workpiece coordinate system W-CS:

Workpiece Coordinate System

Working plane coordinate system WPL-CS:

Working Plane Coordinate System

Input coordinate system I-CS:

Input Coordinate System

Tool coordinate system T-CS:

Tool Coordinate System

All reference systems build upon each other. They are

subject to the kinematic chain of the specific machine

tool.

The machine coordinate system is the reference system.

3

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

77

Loading...

Loading...