Programming contours | Path contours — Cartesian coordinates

5

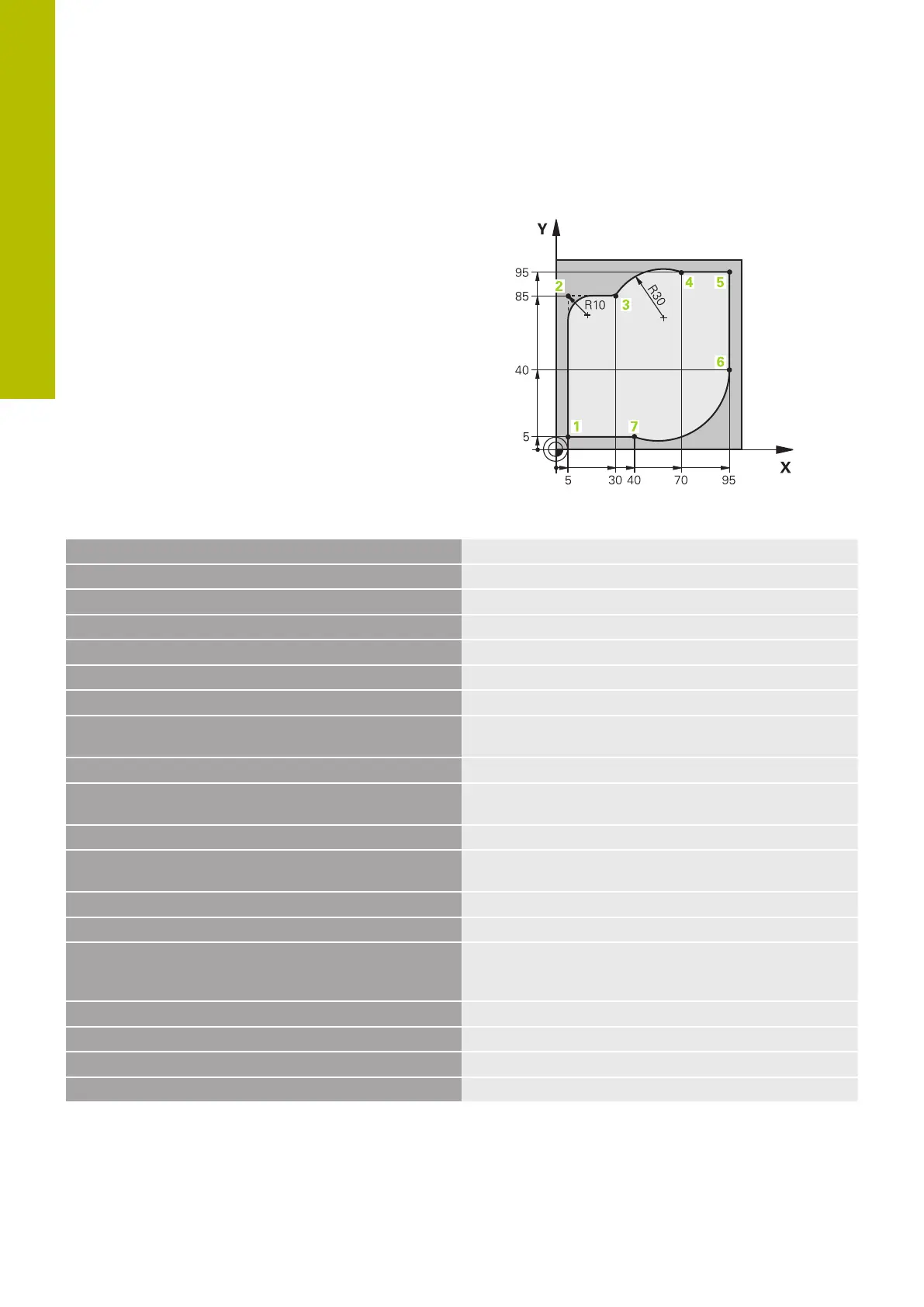

Example: Circular movements with Cartesian coordinates

0 BEGIN PGM CIRCULAR MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

Define the workpiece blank for the machining simulation

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 1 Z S4000

Tool call with spindle axis and spindle speed

4 L Z+250 R0 FMAX

Retract the tool in the spindle axis at rapid traverse FMAX

5 L X-10 Y-10 R0 FMAX

Pre-position the tool

6 L Z-5 R0 F1000 M3

Move to working depth at feed rate F=1000mm/min

7 APPR LCT X+5 Y+5 R5 RL F300

Approach the contour at point1 on a circular path with

tangential connection

8 L X+5 Y+85

Program the first straight line for corner2

9 RND R10 F150

Program a rounding with R= 10mm, feed rate F=150mm/

min

10 L X+30 Y+85

Move to point 3: starting point of the circular path CR

11 CR X+70 Y+95 R+30 DR-

Move to point 4: end point of the circular path CR, with radius

R= 30mm

12 L X+95

Move to point 5

13 L X+95 Y+40

Move to point 6: starting point of the circular path CT

14 CT X+40 Y+5

Move to point 7: end point of the circular path CT, arc with

tangential connection to point6; the control calculates the

radius automatically

15 L X+5

Move to last contour point 1

16 DEP LCT X-20 Y-20 R5 F1000

Depart contour on a circular path with tangential connection

17 L Z+250 R0 FMAX M2

Retract the tool, end program

18 END PGM CIRCULAR MM

166

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

Loading...

Loading...