Miscellaneous functions | Miscellaneous functions for coordinate entries

7

7.3 Miscellaneous functions for coordinate

entries

Programming machine-referenced coordinates: M91/

M92

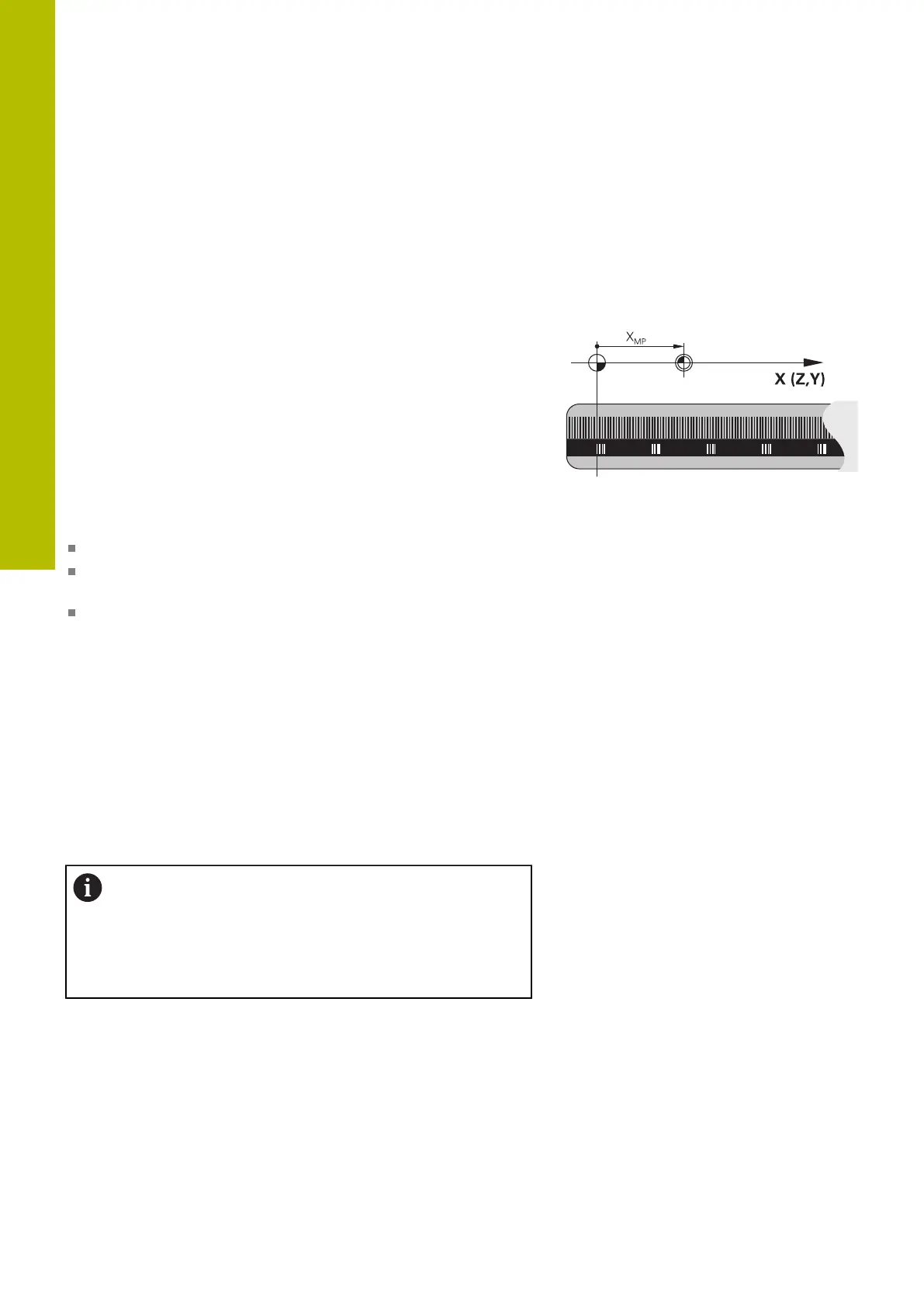

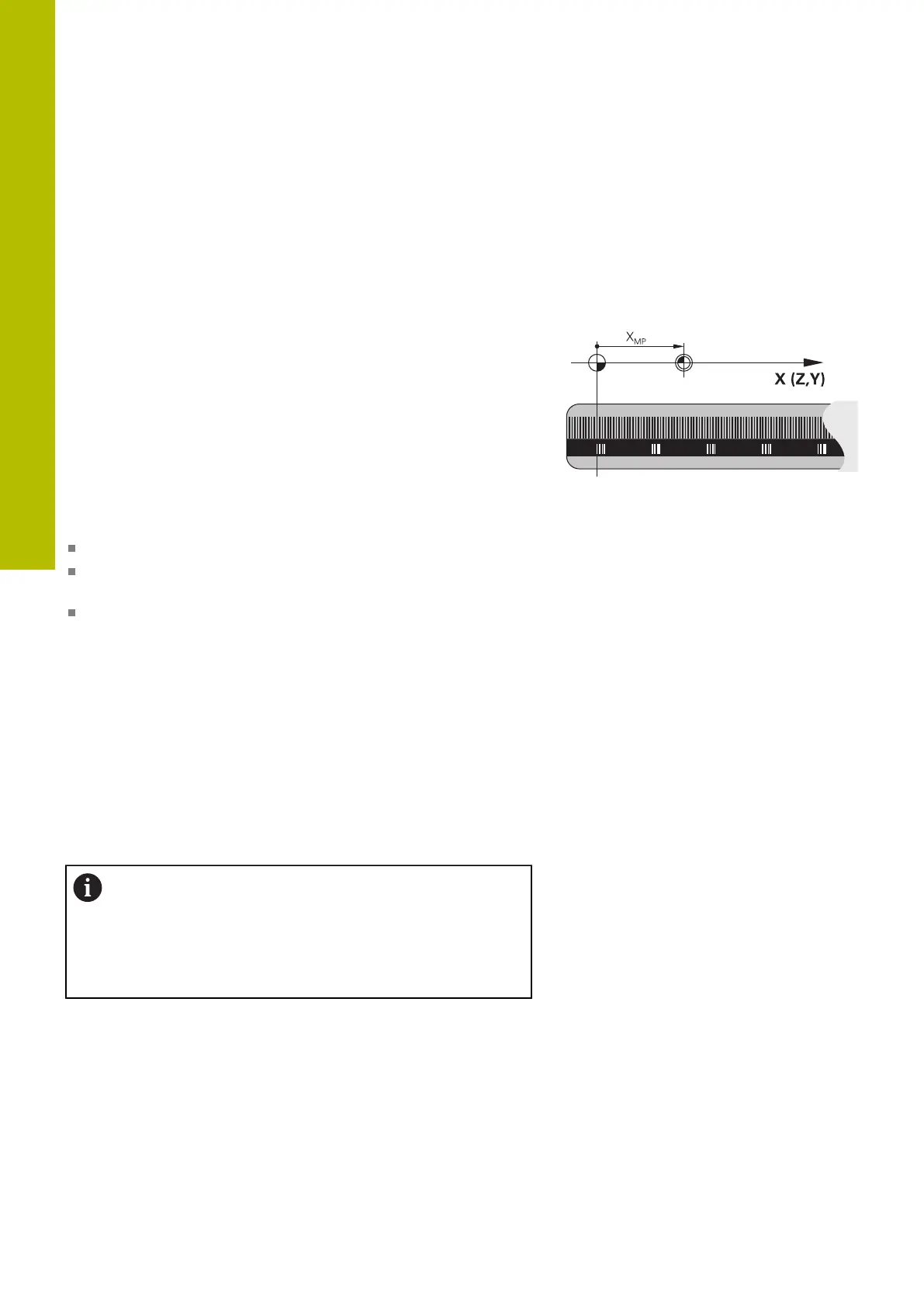

Scale datum

On the scale, a reference mark indicates the position of the scale

datum.

Machine datum

The machine datum is required for the following tasks:

Define the axis traverse limits (software limit switches)

Approach machine-referenced positions (such as tool change

positions)

Set a workpiece preset

The distance in each axis from the scale datum to the machine

datum is defined by the machine tool builder in a machine

parameter.

Standard behavior

The control references the coordinates to the workpiece datum.

Further information: User's Manual for Setup, Testing and Running

NC Programs

Behavior with M91—Machine datum

If you want the coordinates in a positioning block to be referenced to

the machine datum, enter M91 into these NC blocks.

If you program incremental coordinates in an NC block

with the miscellaneous function M91, then these

coordinates are relative to the last position programmed

with M91. If the active NC program does not contain

a position programmed with M91, the coordinates

reference the current tool position.

The coordinate values on the control's screen are referenced to

the machine datum. Switch the display of coordinates in the status

display to REF.

Further information: User's Manual for Setup, Testing and Running

NC Programs

226

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

Loading...

Loading...