Programming contours | Approaching and departing a contour

5

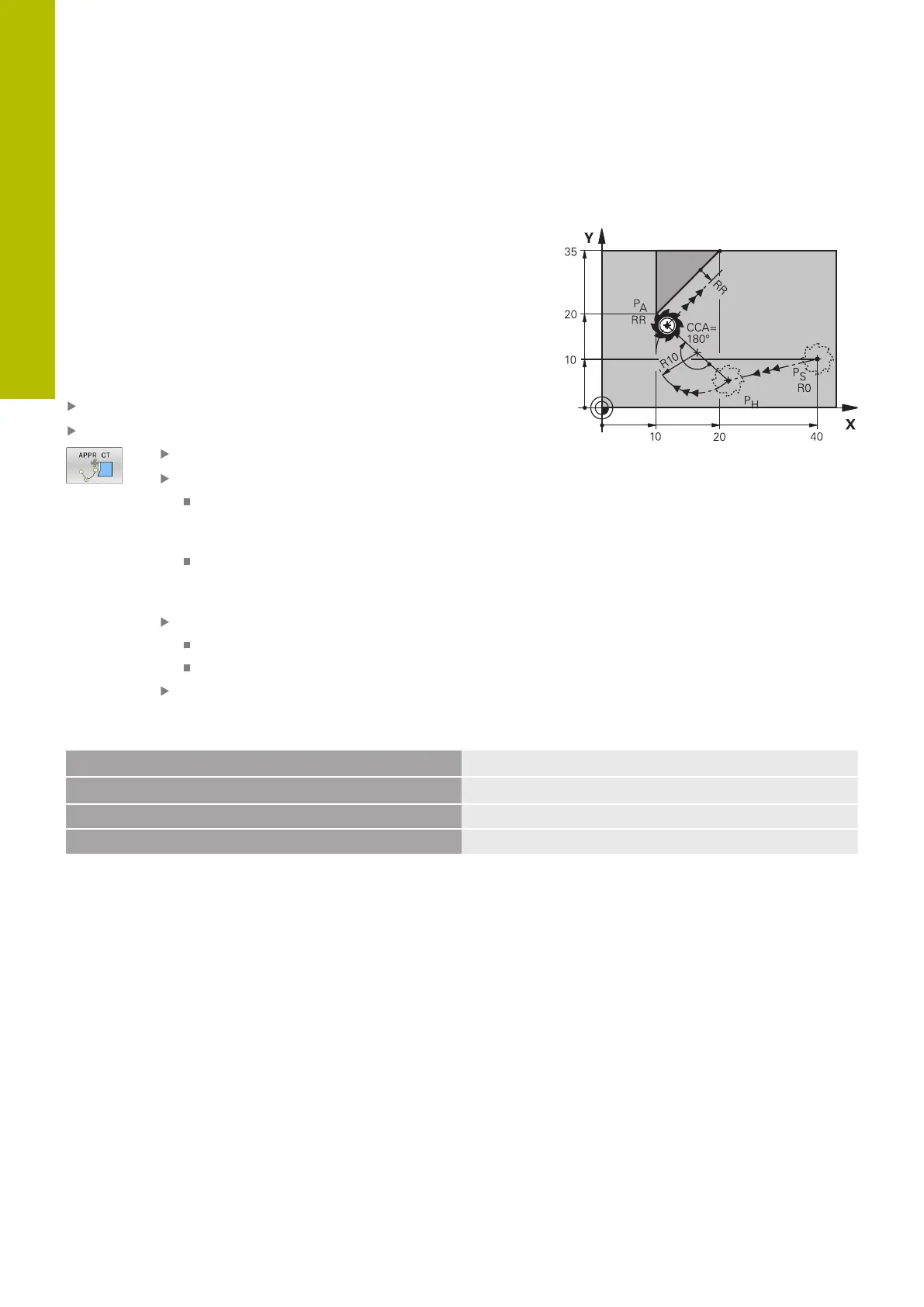

Approaching on a circular path with tangential

connection: APPR CT

The tool moves on a straight line from the starting point P

S

to an

auxiliary point P

H

. It then moves from PH to the first contour point

PA following a circular arc that is tangential to the first contour

element.

The arc from P

H

to P

A

is determined through the radius R and

the center angle CCA. The direction of rotation of the circular arc

is automatically derived from the tool path for the first contour

element.

Use any path function to approach the starting point P

S

.

Initiate the dialog with the APPR DEP key and APPR CT soft key

Coordinates of the first contour point P

A

Radius R of the circular arc

If the tool should approach the workpiece

in the direction defined by the radius

compensation: Enter R as a positive value

If the tool should approach the workpiece

opposite to the radius compensation: Enter R

as a negative value.

Center angle CCA of the arc

CCA can be entered only as a positive value.

Maximum input value 360°

Radius compensation RR/RL for machining

Example

7 L X+40 Y+10 R0 FMAX M3

Approach P

S

without radius compensation

8 APPR CT X+10 Y+20 Z-10 CCA180 R+10 RR F100

P

A

with radius compensation RR, radius R10

9 L X+20 Y+35

End point of the first contour element

10 L ...

Next contour element

150

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

Loading...

Loading...