First steps | Programming the first part

2

Recommended program layout for simple cycle programs

Example

0 BEGIN PGM BSBCYC MM

1 BLK FORM 0.1 Z X... Y... Z...

2 BLK FORM 0.2 X... Y... Z...

3 TOOL CALL 5 Z S5000

4 L Z+250 R0 FMAX M3

5 PATTERN DEF POS1( X... Y... Z... ) ...

6 CYCL DEF...

7 CYCL CALL PAT FMAX M8

8 L Z+250 R0 FMAX M2

9 END PGM BSBCYC MM

1 Call tool, define tool axis

2 Retract the tool; turn on spindle

3 Define the machining positions

4 Define the machining cycle

5 Call the cycle, and switch on the coolant

6 Retract the tool, end the NC program

Further information on this topic

Cycle programming

Further information: User's Manual for Programming of

Machining Cycles

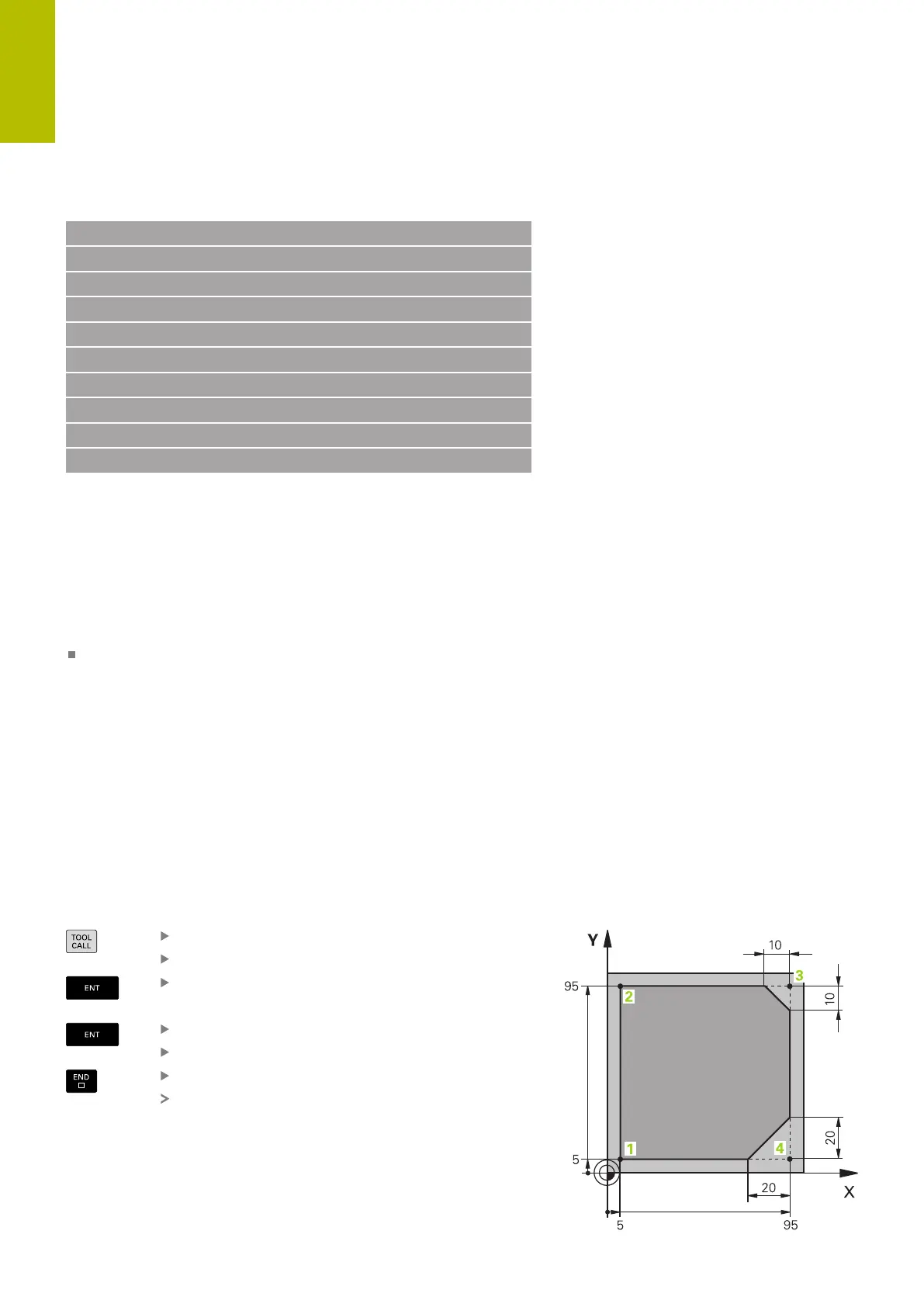

Programming a simple contour

Suppose you want to mill a single time around the contour shown on

the right at a depth of 5mm. You have already defined the workpiece

blank.

After you have opened an NC block with a function key, the control

will prompt you to enter all of the data in the header using dialog

texts.

To program the contour:

Call the tool

Press the TOOL CALL key

Enter the tool data, e.g., tool number 16

Press the ENT key

Confirm the tool axis Z with the ENT key

Enter the spindle speed (e.g., 6500)

Press the END key

The control completes the NC block.

56

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

Loading...

Loading...