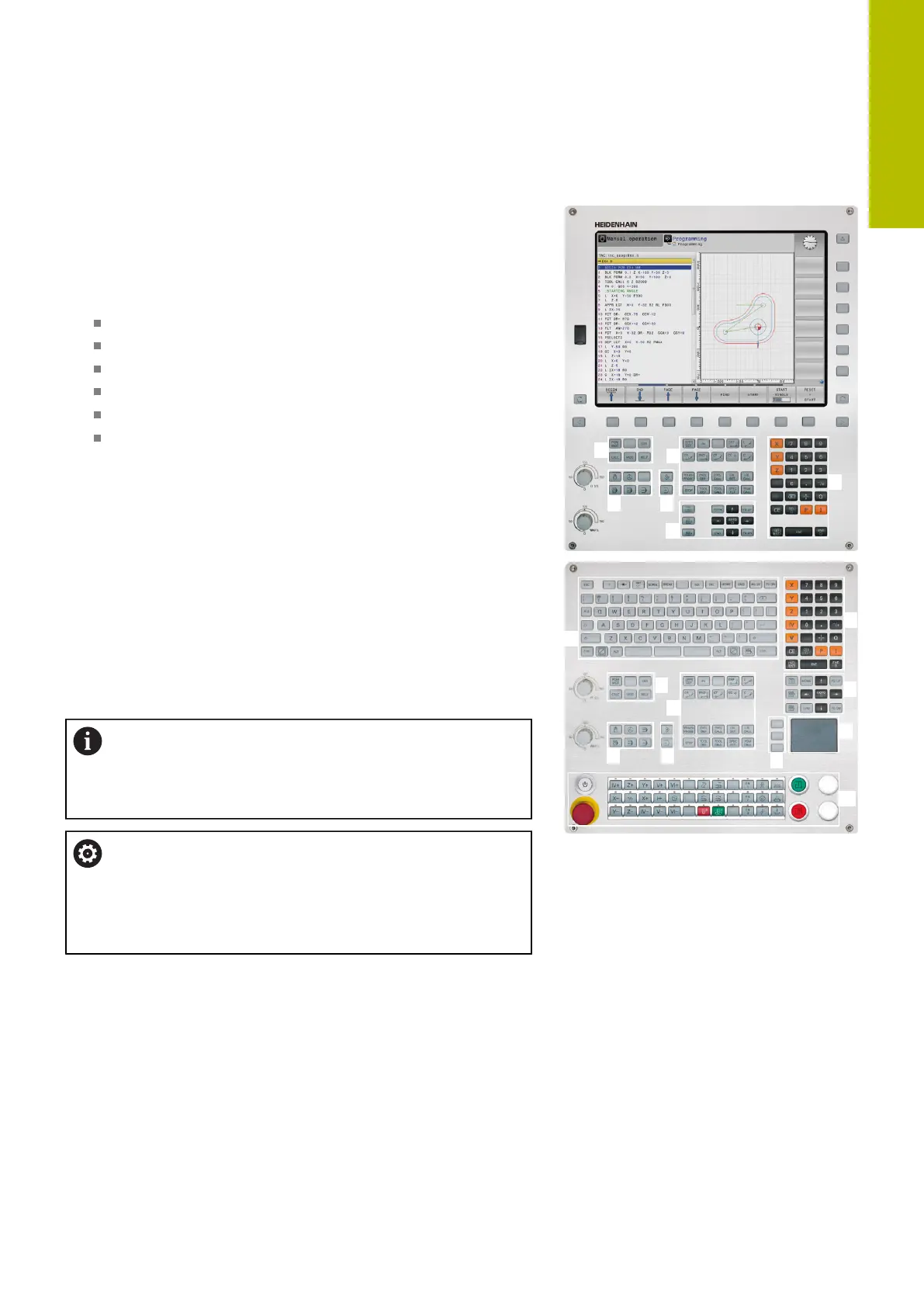

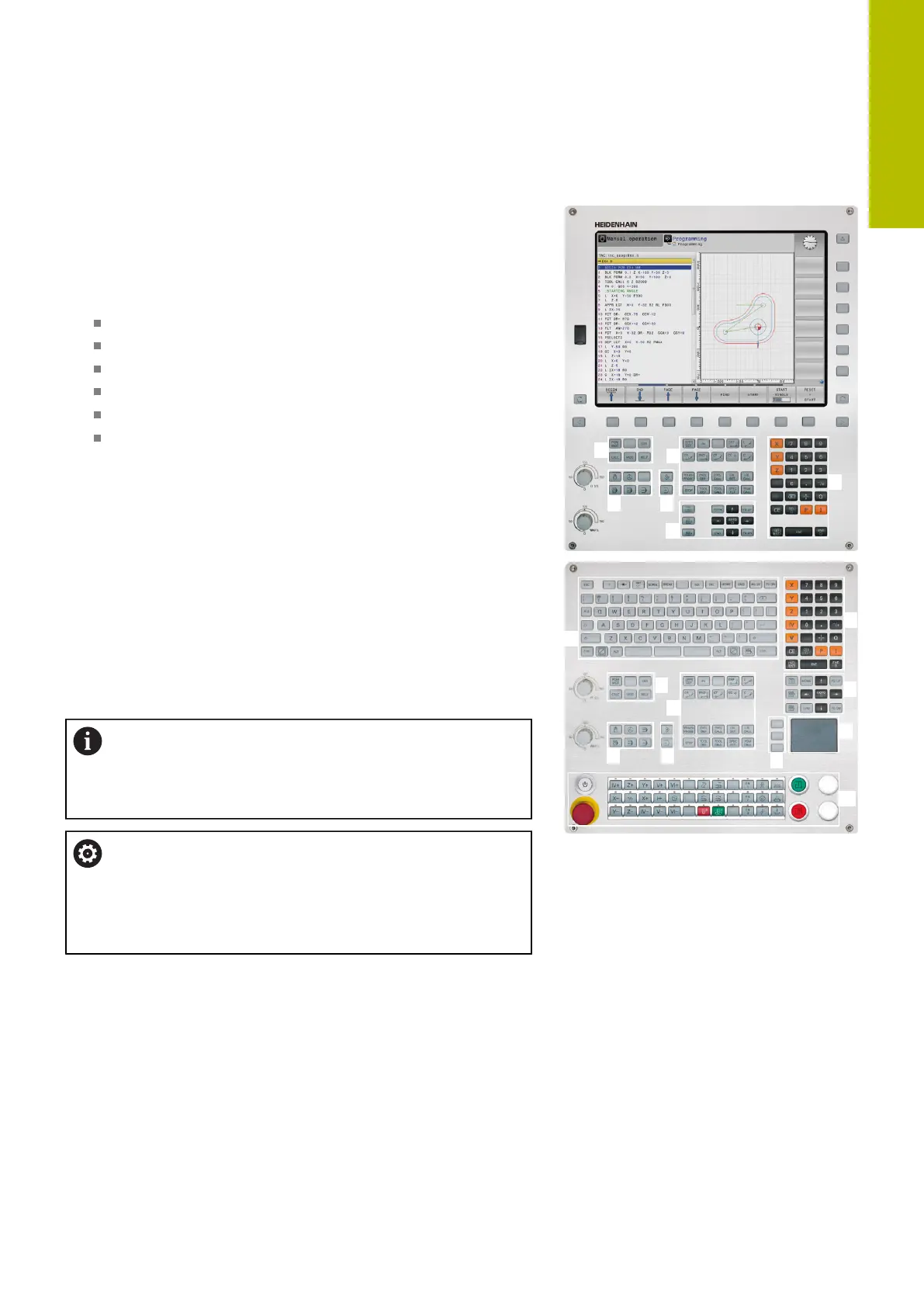

Fundamentals | Visual display unit and operating panel

Operating panel

The TNC620 can be delivered with an integrated operating panel. As

an alternative, the TNC620 is also available with a separate monitor

and an external operating panel with alphabetic keyboard.

1 Alphabetic keyboard for entering texts and file names, as well

as for ISO programming

2 File manager

Calculator

MOD function

HELP function

Show error messages

Toggle between the operating modes

3 Programming modes

4 Machine operating modes

5 Initiating programming dialogs

6 Navigation keys and GOTO jump command

7 Numerical input and axis selection

8 Touchpad

9 Mouse buttons

10 Machine operating panel

More information: Machine manual

The functions of the individual keys are described on the inside front

cover.

If you are using a TNC620 with touch control, you can

replace some keystrokes with gestures.

Further information: "Operating the touchscreen",

Page 535

Refer to your machine manual.

Some machine tool builders do not use the standard

HEIDENHAIN operating panel.

External keys, e.g. NC START or NC STOP, are described in

your machine manual.

3

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

69

Loading...

Loading...