Programming Qparameters | Programming examples

9

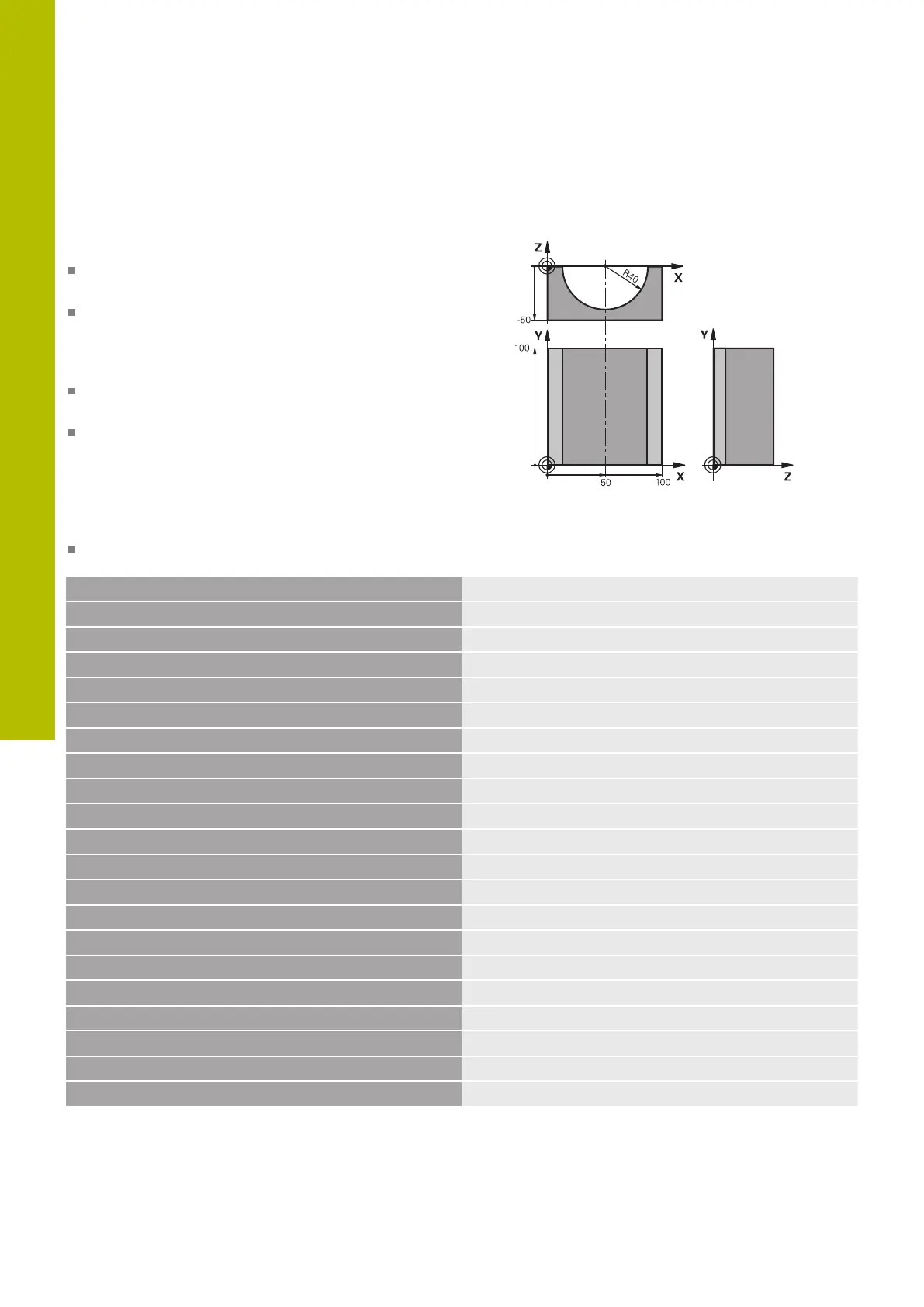

Example: Concave cylinder machined with ball-nose

cutter

Program run

This NCprogram works only with a ball-nose cutter.

The tool length is measured from the sphere center

The contour of the cylinder is approximated by many

short line segments (defined in Q13). The more line

segments you define, the smoother the contour

becomes.

The cylinder is milled in longitudinal cuts (here:

parallel to the Y axis).

The milling direction is determined with the starting

angle and end angle in space:

Machining direction clockwise:

Starting angle > end angle

Machining direction counterclockwise:

Starting angle < end angle

The tool radius is compensated automatically

0 BEGIN PGM CYLIN MM

1 FN 0: Q1 = +50

Center in X axis

2 FN 0: Q2 = +0

Center in Y axis

3 FN 0: Q3 = +0

Center in Z axis

4 FN 0: Q4 = +90

Starting angle in space (Z/X plane)

5 FN 0: Q5 = +270

End angle in space (Z/X plane)

6 FN 0: Q6 = +40

Cylinder radius

7 FN 0: Q7 = +100

Length of the cylinder

8 FN 0: Q8 = +0

Rotational position in the X/Y plane

9 FN 0: Q10 = +5

Allowance for cylinder radius

10 FN 0: Q11 = +250

Feed rate for plunging

11 FN 0: Q12 = +400

Feed rate for milling

12 FN 0: Q13 = +90

Number of cuts

13 BLK FORM 0.1 Z X+0 Y+0 Z-50

Workpiece blank definition

14 BLK FORM 0.2 X+100 Y+100 Z+0

15 TOOL CALL 1 Z S4000

Tool call

16 L Z+250 R0 FMAX

Retract the tool

17 CALL LBL 10

Call machining operation

18 FN 0: Q10 = +0

Reset allowance

19 CALL LBL 10

Call machining operation

20 L Z+100 R0 FMAX M2

Retract the tool, end program

354

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

Loading...

Loading...