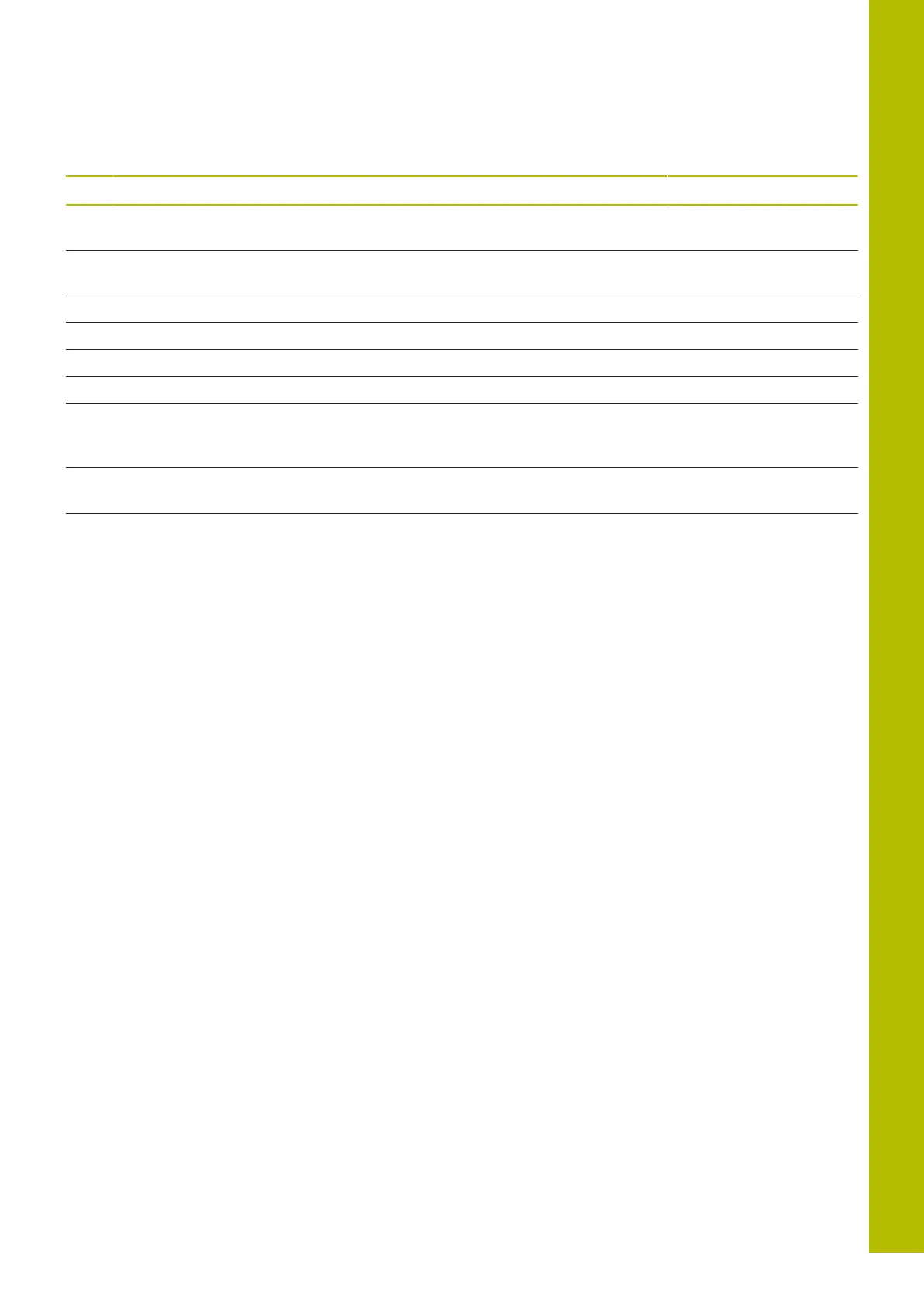

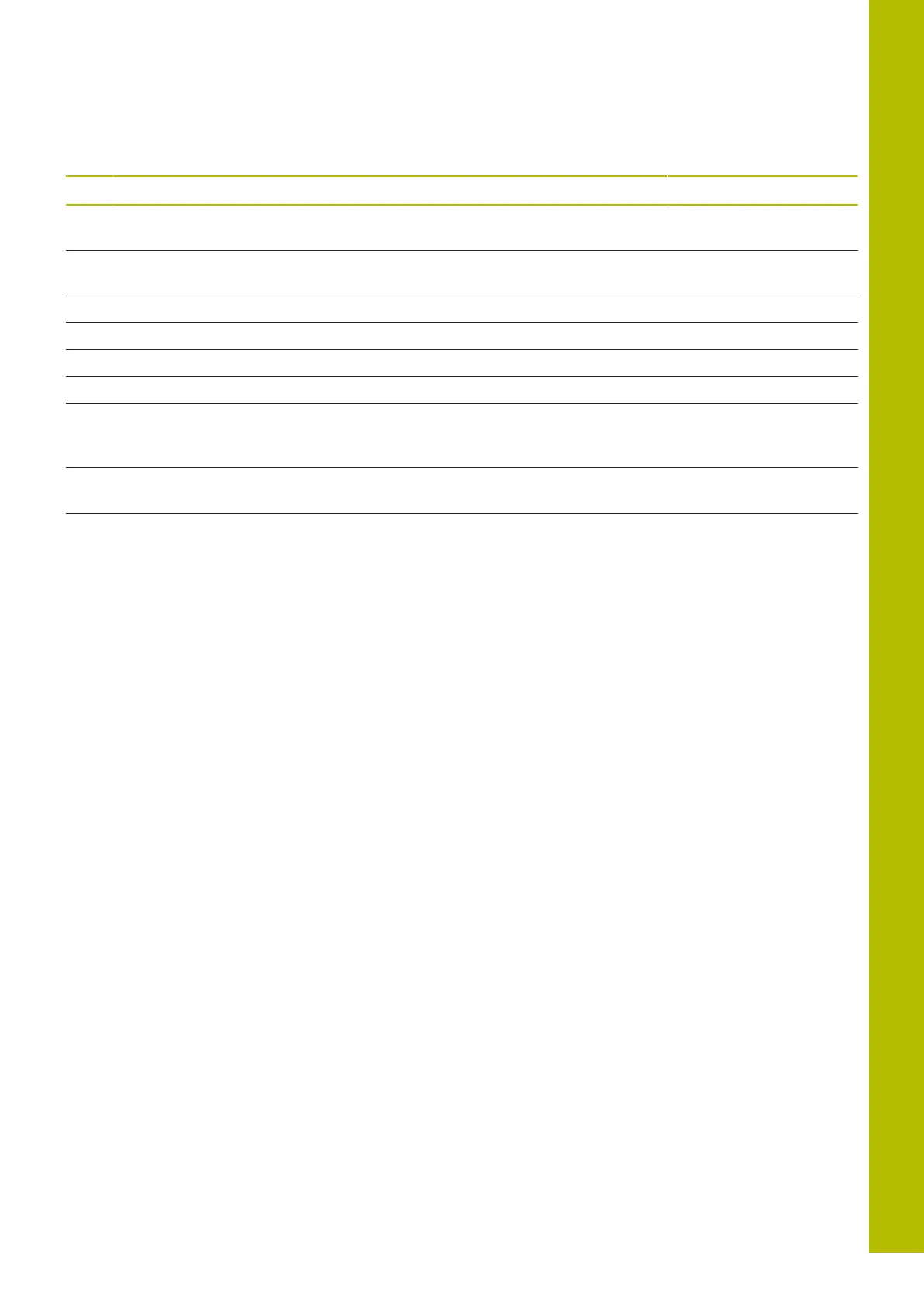

Tables and overviews | Overview tables

M Effect Effective at block Start End Page

M130 Within the positioning block: Points are referenced to the untilted coordinate

system

■ 228

M136

M137

Feed rate F in millimeters per spindle revolution

Reset M136

■ 232

M138 Selection of tilted axes ■ 467

M140 Retraction from the contour in the tool-axis direction ■ 237

M141 Suppress touch probe monitoring ■ 239

M143 Delete basic rotation ■ 239

M144

M145

Compensating the machine’s kinematic configuration for ACTUAL/NOMINAL

positions at end of block

Reset M144

■

■

468

M148

M149

Automatically retract tool from the contour at an NC stop

Reset M148

■

■

240

M197 Corner rounding ■ ■ 241

15

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

591

Loading...

Loading...