First steps | Programming the first part

2

Example

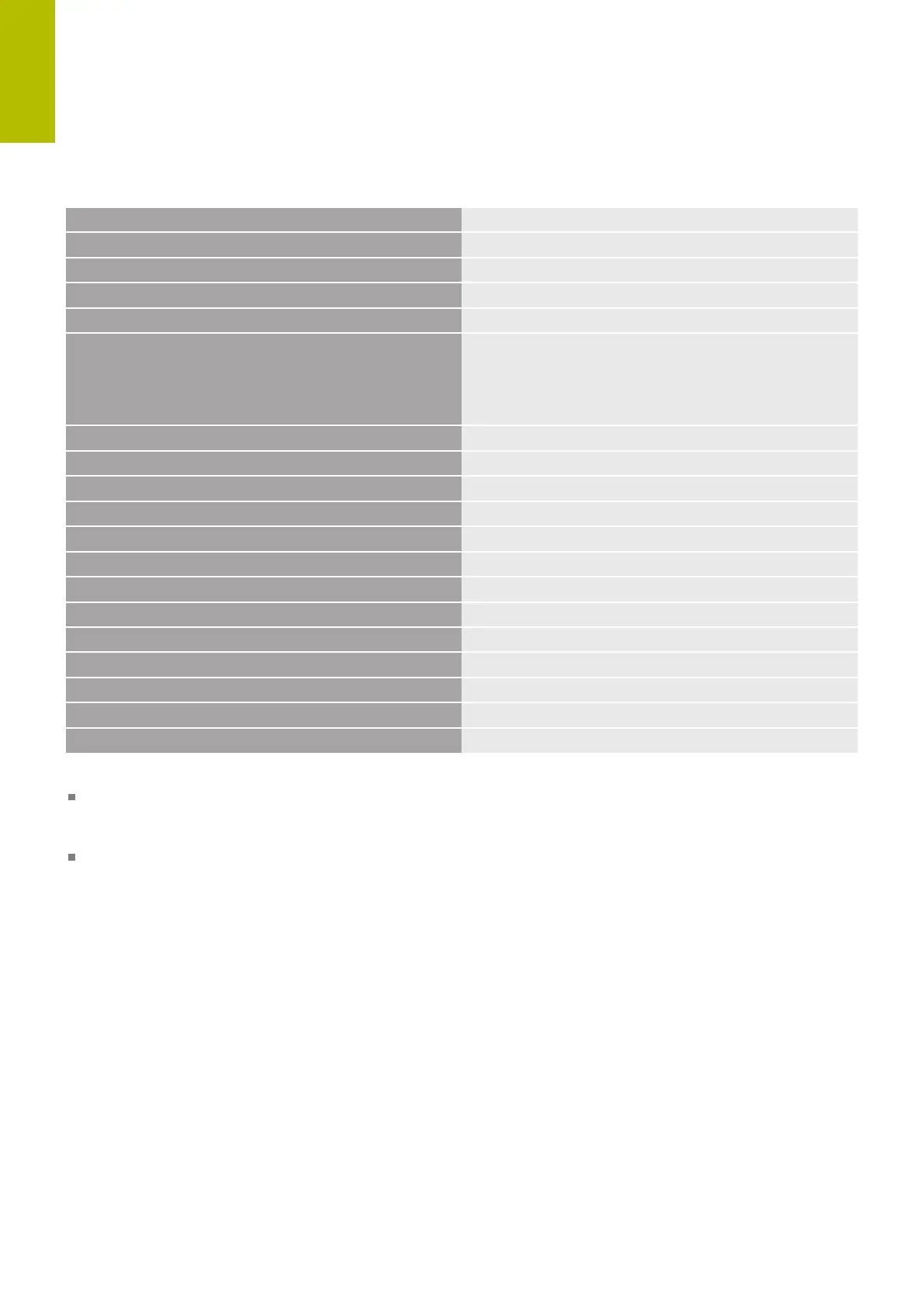

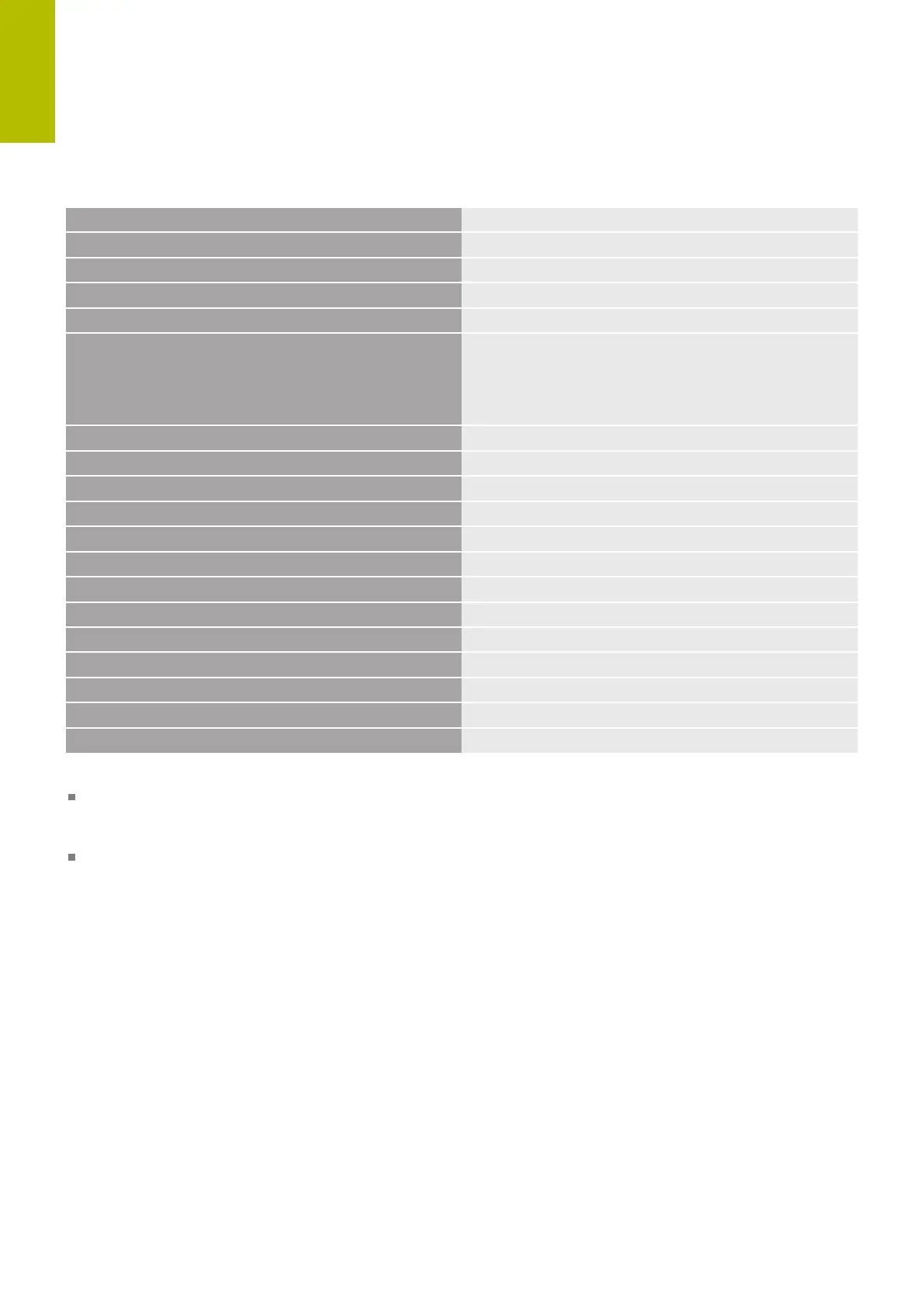

0 BEGIN PGM C200 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

Workpiece blank definition

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 5 Z S4500

Tool call

4 L Z+250 R0 FMAX M3

Retract the tool; turn on spindle

5 PATTERN DEF

POS1 (X+10 Y+10 Z+0)

POS2 (X+10 Y+90 Z+0)

POS3 (X+90 Y+90 Z+0)

POS4 (X+90 Y+10 Z+0)

Define the machining positions

6 CYCL DEF 200 DRILLING

Define the cycle

Q200=2 ;SET-UP CLEARANCE

Q201=-20 ;DEPTH

Q206=250 ;FEED RATE FOR PLNGNG

Q202=5 ;PLUNGING DEPTH

Q210=0 ;DWELL TIME AT TOP

Q203=-10 ;SURFACE COORDINATE

Q204=20 ;2ND SET-UP CLEARANCE

Q211=0.2 ;DWELL TIME AT DEPTH

Q395=0 ;DEPTH REFERENCE

7 CYCL CALL PAT FMAX M8

Turn on coolant; call cycle

8 L Z+250 R0 FMAX M30

Retract the tool, end program

9 END PGM C200 MM

Further information on this topic

Creating a new NC program

Further information: "Creating and entering NC programs",

Page 90

Cycle programming

Further information: User's Manual for Programming of

Machining Cycles

64

HEIDENHAIN | TNC620 | Klartext Programming User's Manual | 01/2022

Loading...

Loading...