OPERATION

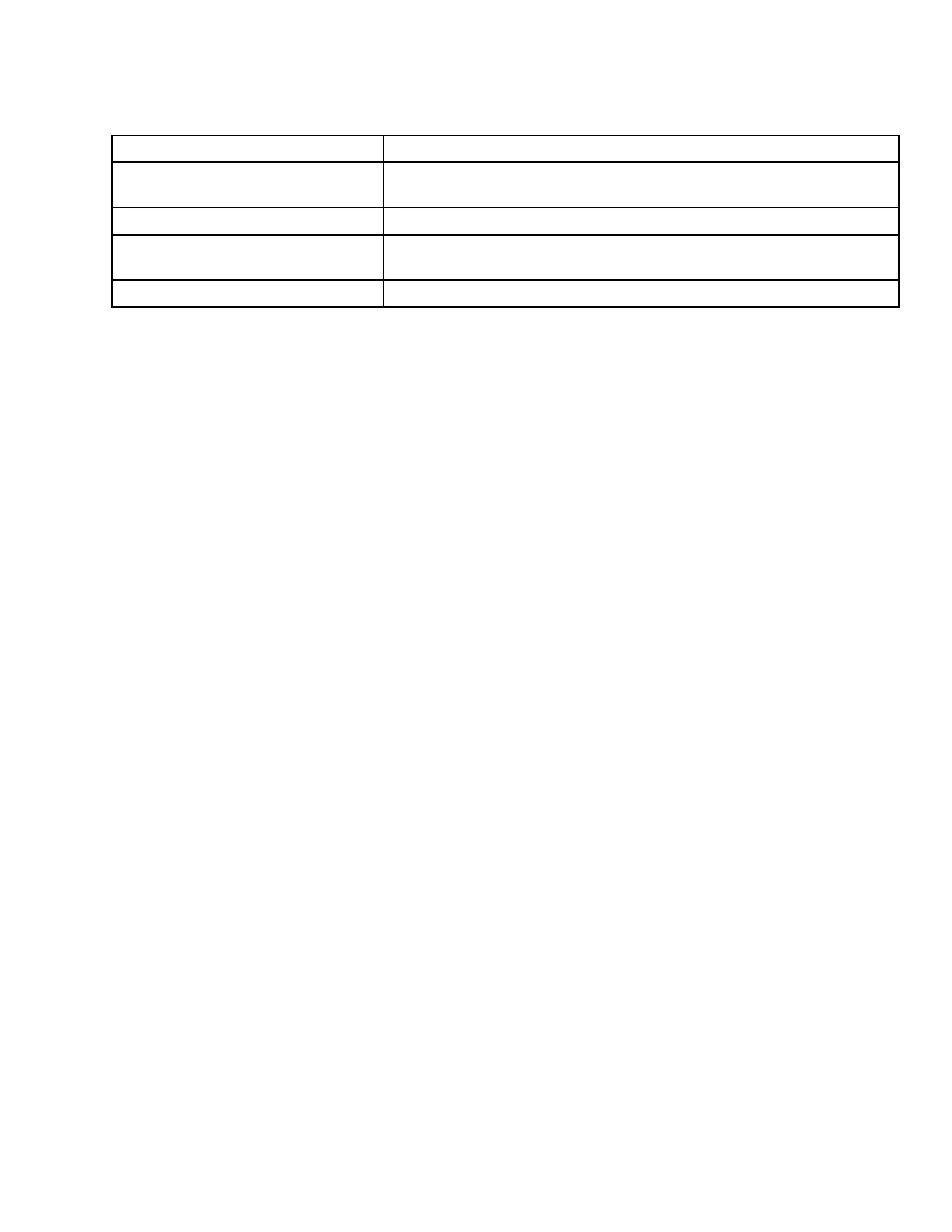

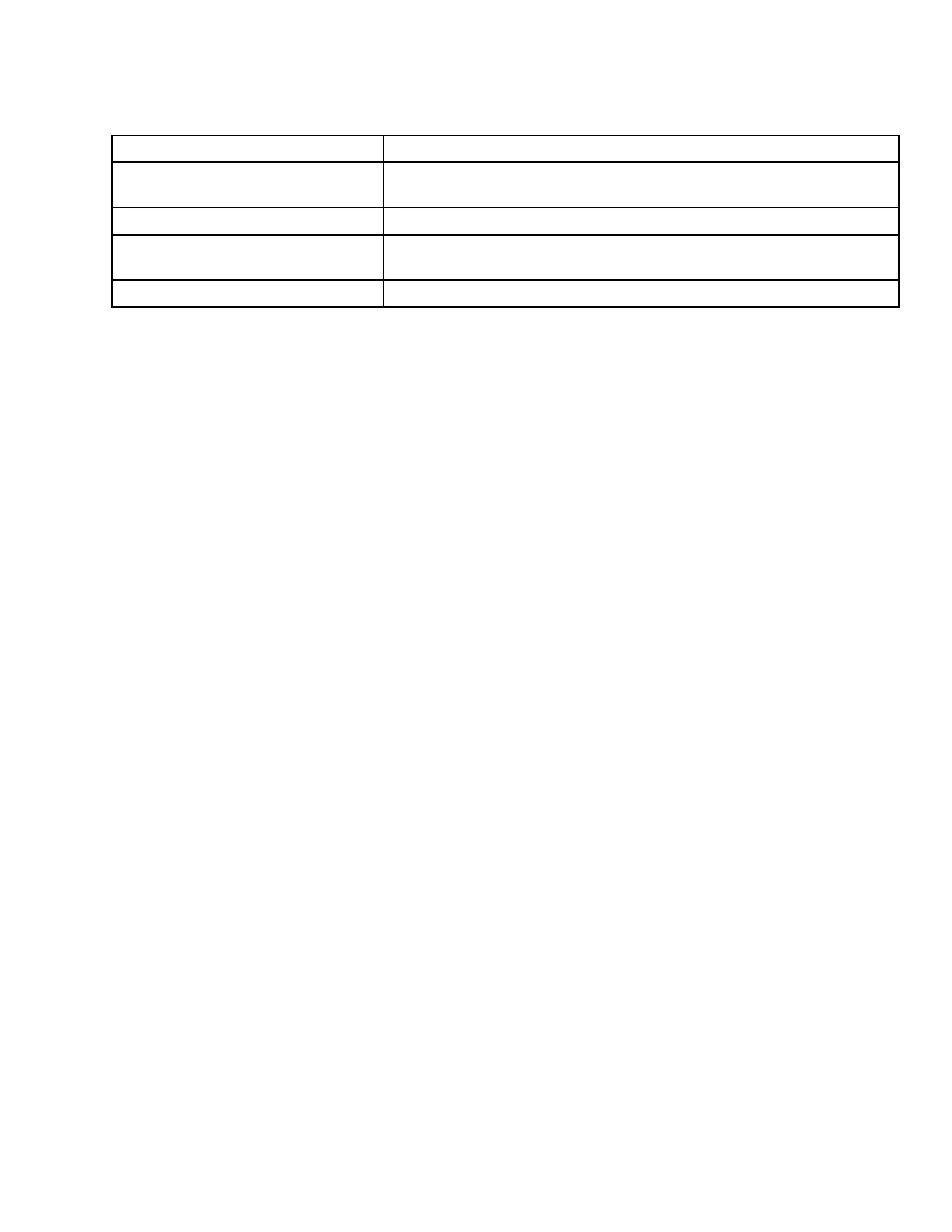

Table 3.11 Recommended Windrow Characteristics

Characterist

ic Advantage

High and fluffy

Enables a ir flow through windrow which is more important to the curing

process than direct sunlight

Consistent formation (not bunching) Permits an even flow of material into the baler, chopper, etc.

Even distri

bution of material

across wind

row

Results in even and consistent bales to min imize handling a nd

stacking problems

Properly conditioned

Prevents excessive leaf damage

3.16.5 Driving on Windrow

Driving o

n previously cut windrows that will not be raked can lengthen drying time by a full day. If practical, set

forming s

hields to produce a narrower windrow that the machine can straddle.

NOTE:

Driving on the windrow in high-yield crops may be unavoidable if a full width windrow is necessary.

3.16.6 Raking and Tedding

Raking

or tedding speeds up drying; however, the resulting leaf loss may outweigh the benefits. There is little o r no

advant

age to raking or tedding if the ground beneath the windrow is dry.

Large w

indrows on damp or wet ground should be turned over when moisture levels reach 40–50%. Hay should not

be rak

ed or tedded at moisture levels below 25%, however, or excessive yield loss will result.

3.16.

7 Using Chemical Drying Agents

Hay drying agents work by removing wax from legume surfaces and enabling w ater to escape and evaporate faster.

However, treated hay lying on wet ground will absorb ground moisture faster.

Before deciding to use a drying agent, carefully compare the relative costs and benefits for your area.

147910 103 Revision A

Loading...

Loading...