MAINTENANCE AND SERVICING

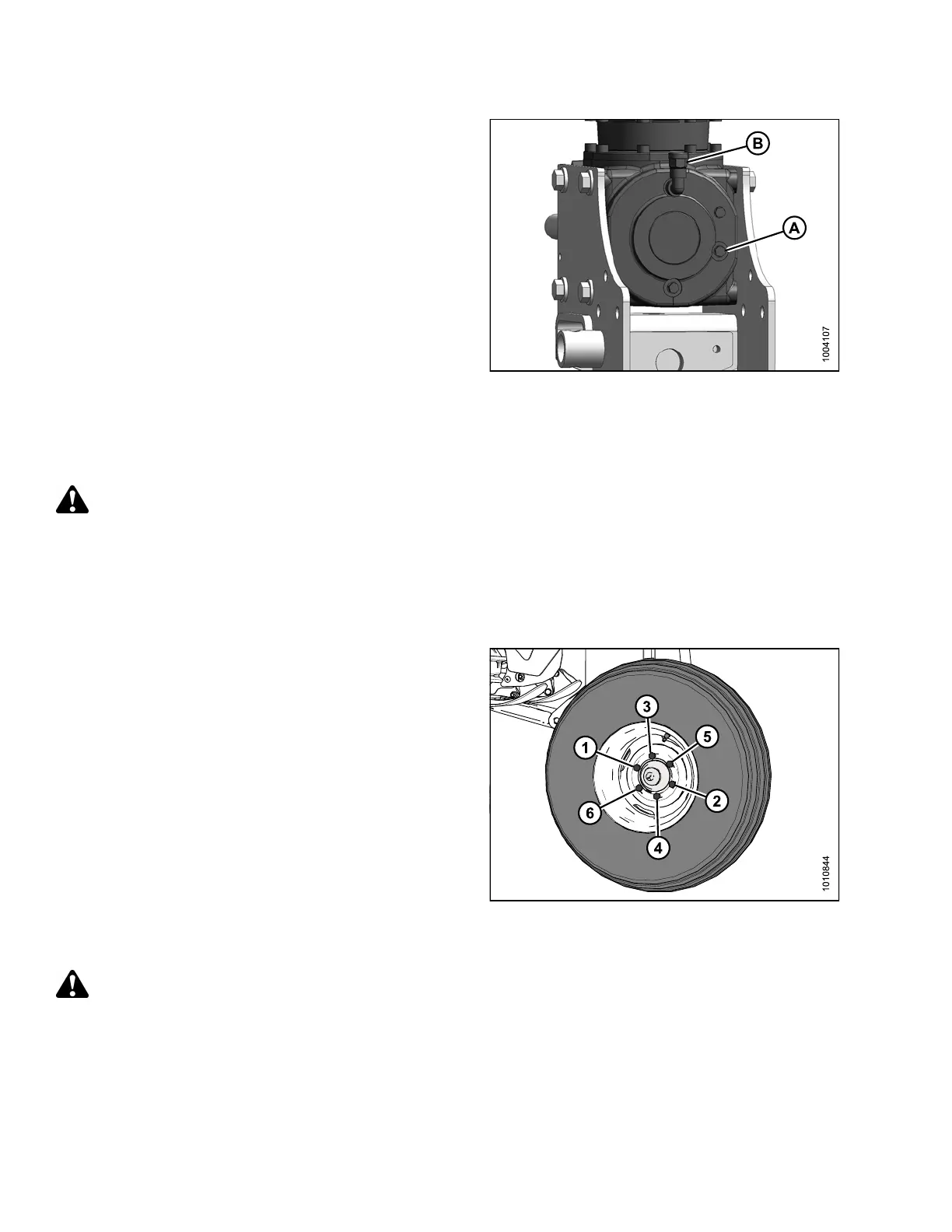

1. Clean area around check plug (A) and breather/filler

plug (B).

2. Remove check plug (A) and breather/filler plug (B).

3. Ensure lubricant level is visible or begins to d rain

through check port (A), and add gear lubricant to

gearbox through port (B) as required. Refer to 7.1

Recommended Lubricants, page 259 for capacity of

gearbox.

4. Reinstall check plug (A) and breather/filler plug (B)

and tighten.

Figure 4.226: Swivel Gearbox

4.5.12 Wheels and Tires

Checking Wheel Bolts

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove

the key from the ignition before leaving the operator’s seat for any reason.

IMPORTANT:

Check and tighten field wheel bolts and transport system wheel bolts (if installed) after the first hour of operation

and every 100 hours thereafter.

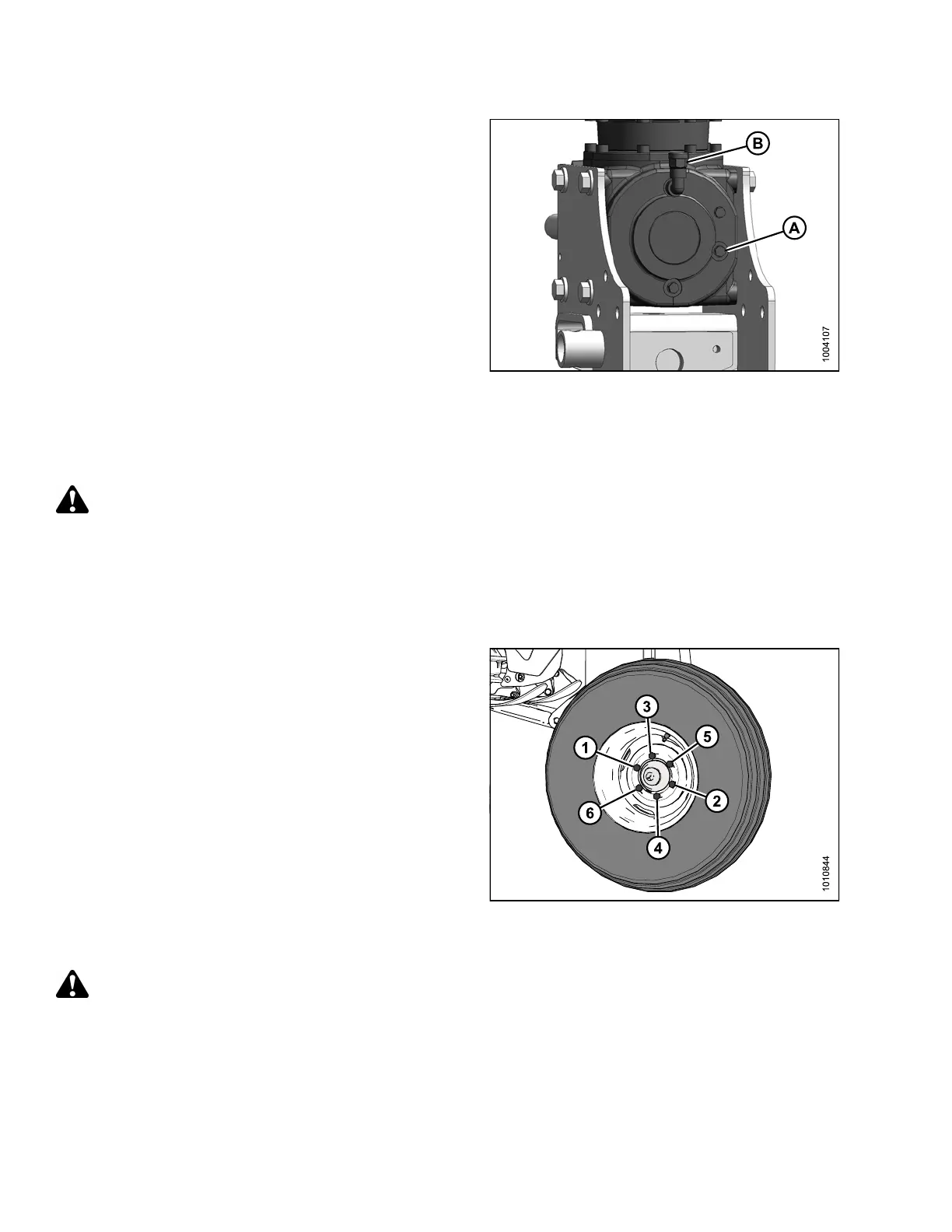

1. Torque wheel bolts to 120 ft·lbf (160 N·m) using the

tightening sequence shown.

NOTE:

Whenever a wheel is installed, check torque

after one hour of operation.

Figure 4.227: Tightening Sequence

Removing Wheels

DANGER

To avoid bodily injury or death from unexpected startup of machine, always stop engine and remove key

from ignition before leaving operator's seat for any reason.

147910 218 Revision A

Loading...

Loading...