OPERATION

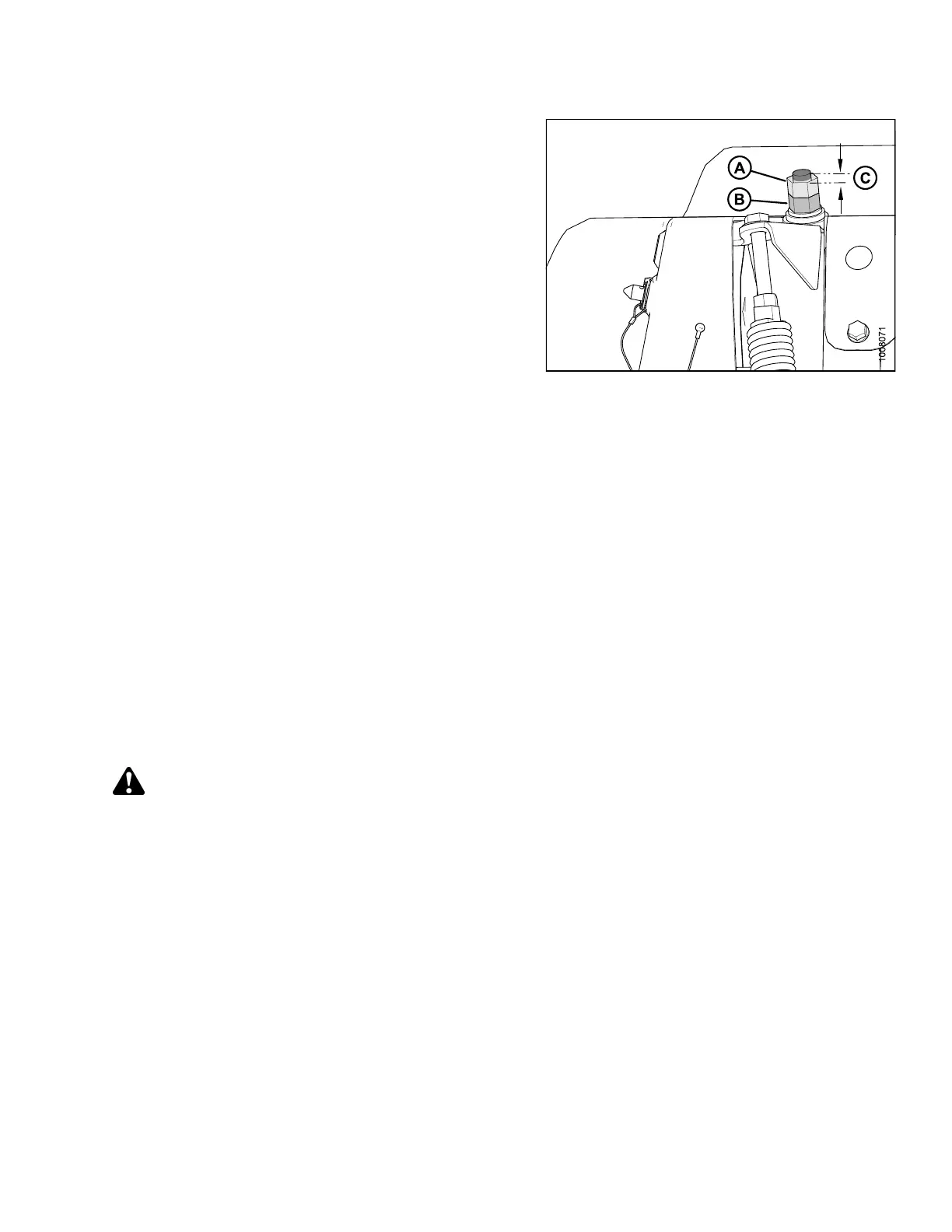

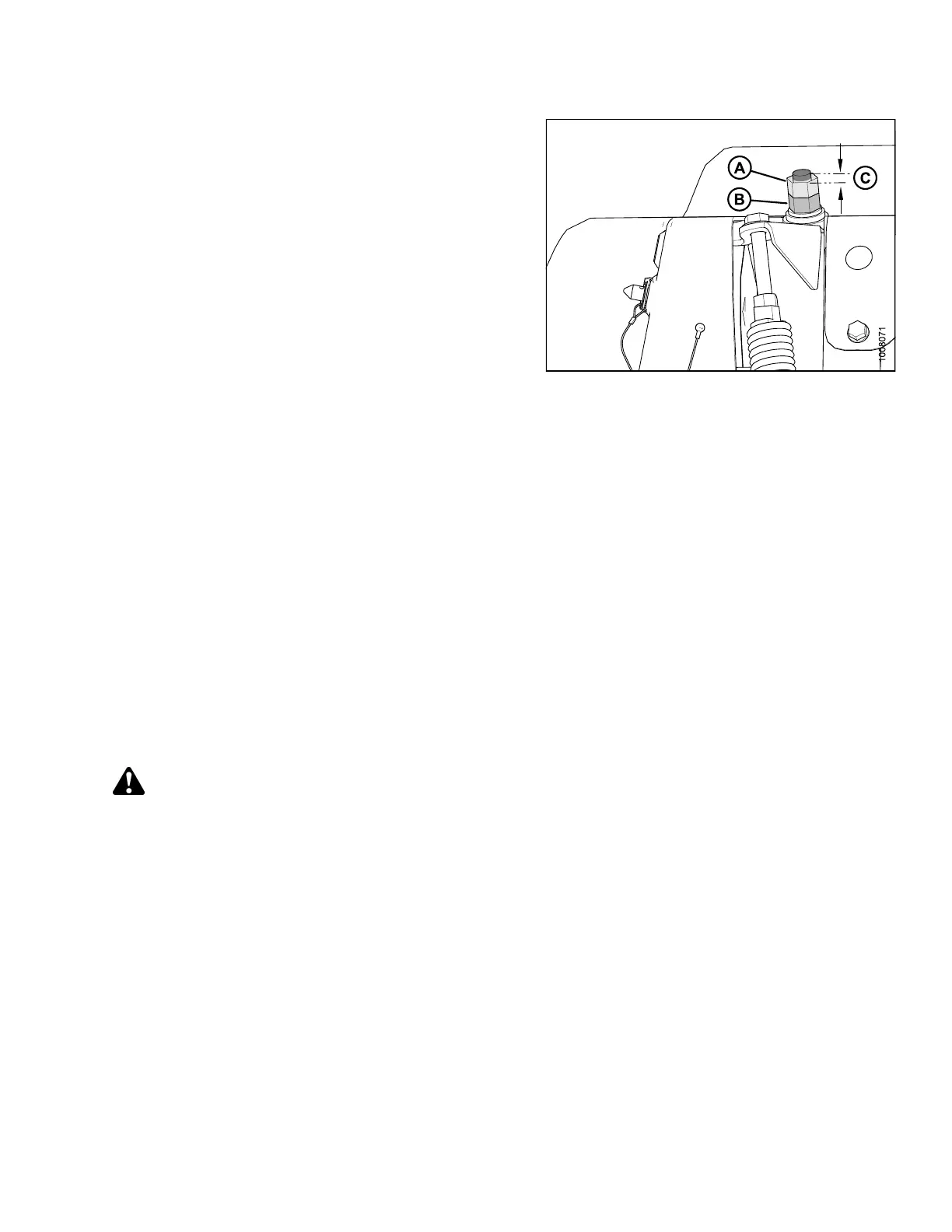

3. Loosen and back off upper jam nut (A) on both sides

of conditioner.

4. Turn stop nut (B) counterclockwise until upper roll rests

on lower r oll. Ensu re both rolls intermes h.

5. Turn stop nut (B) one full turn clockwise to raise the

upper roll and achieve a 1/8 in. (3 mm) roll gap.

NOTE:

the amo unt of thread (C) protruding through the jam

nut is equal to the roll gap.

NOTE:

When adjusting roll gap, be sure the same amount of

thread is protruding on both sides of the conditioner

roll to achieve a consistent gap across the rolls.

6. Tighten jam nuts (A) on both sides.

7. Rotate the rolls manually and use a feeler gauge at the

ends of the rolls to check that the actual gap is no less

than 5/64 in. (2 mm) and no more than 5/32 in. (4 mm).

Figure 3.101: Jam Nut, Adjusting Nut, and

Roll Gap

3.15.7 Roll Tens

ion

Roll tension (the pressure holding the rolls together) is factory-set to maximum and is adjustable.

Heavy crops or tough forage can cause the rolls to separate; therefore, maximum roll tension is required to ensure

that materials are sufficiently crimped.

To prevent over-conditioning of light alfalfa and short grasses, apply less roll tension.

Adjusting Roll Tension

Roll tension is factory-set to maximum and can be adjusted as follows:

DANGER

To avoid bodily injury or death from unexpected startup of machine, always stop engine and remove key

from ignition before leaving operator's seat for any reason.

147910 87 Revision A

Loading...

Loading...