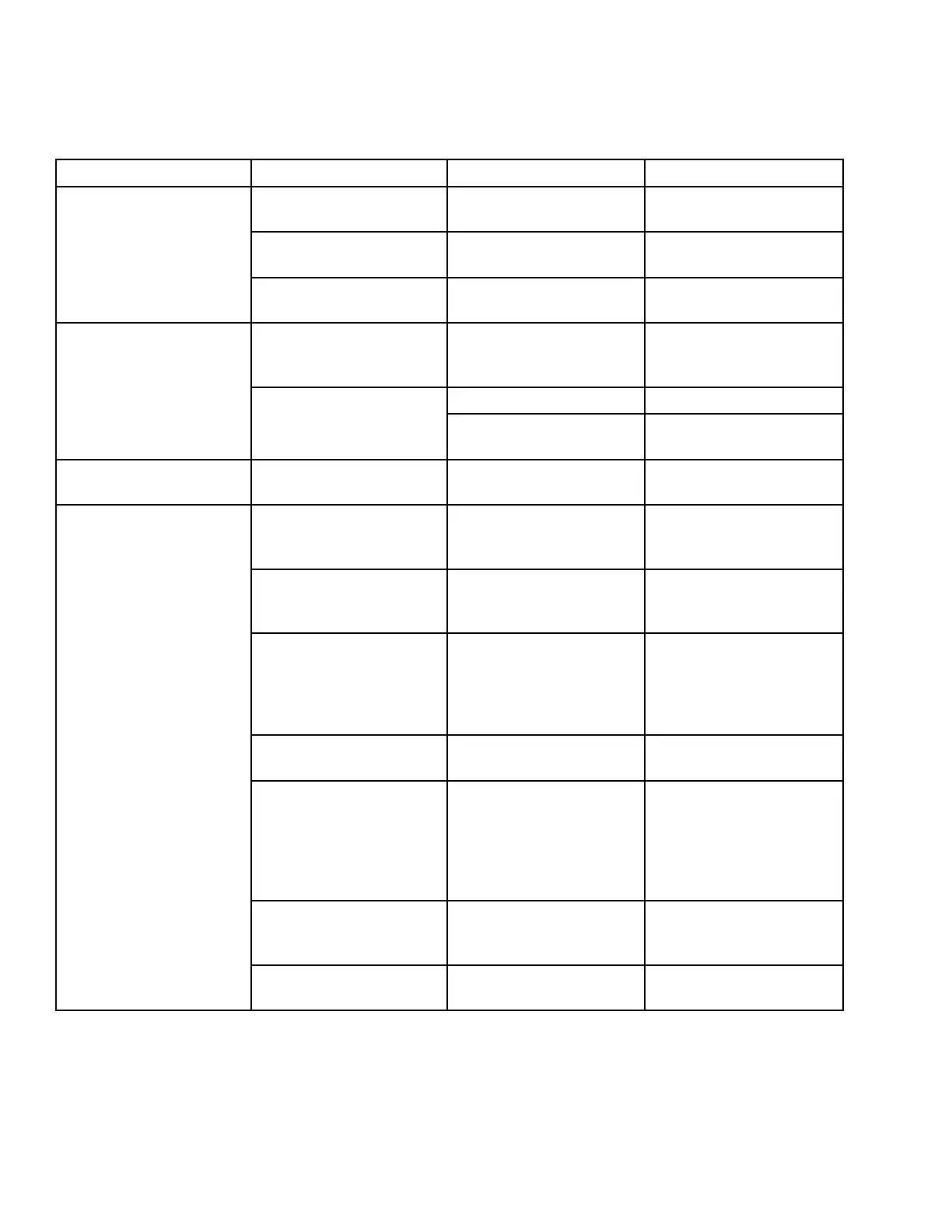

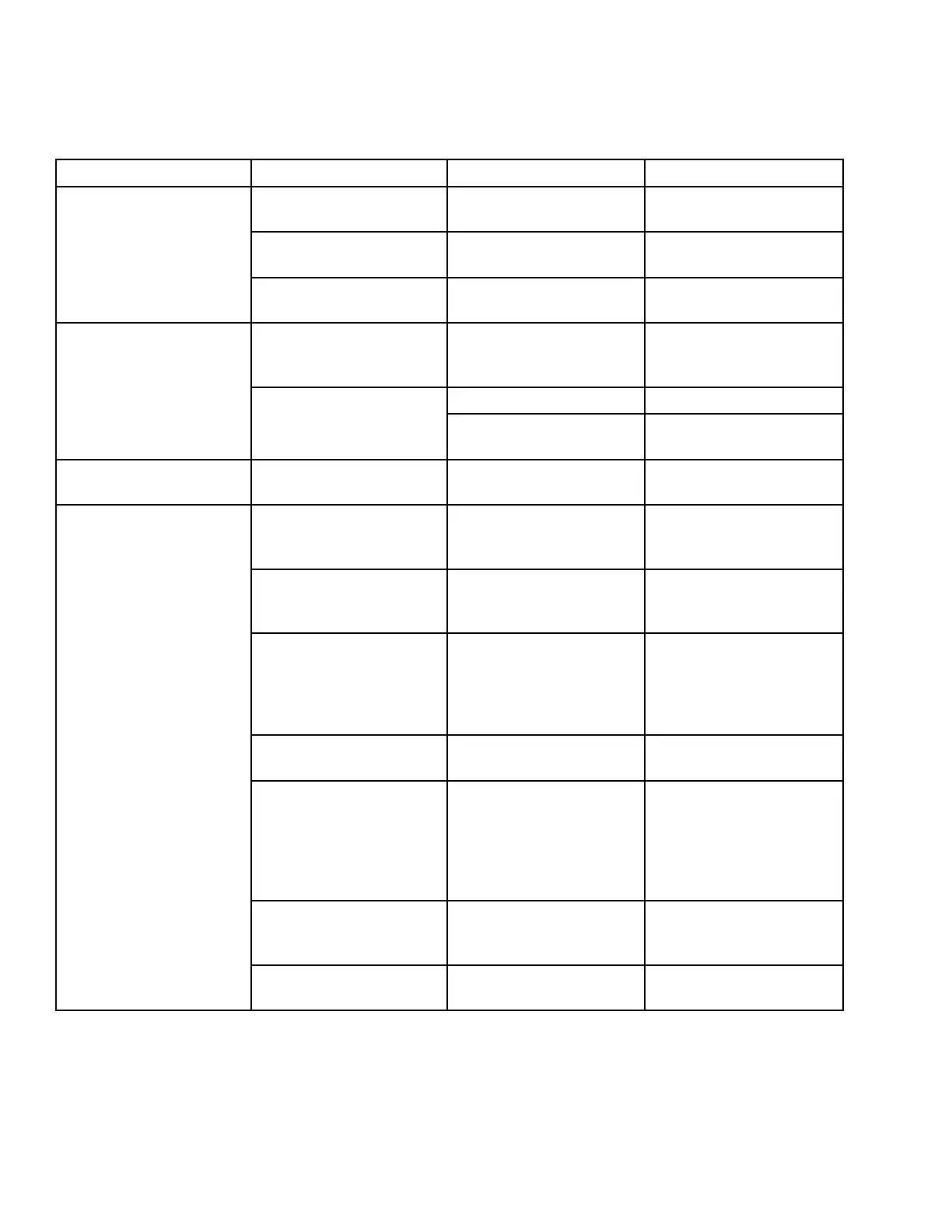

TROUBLESHOOTING

6.2 Troubleshooting Mechanical Issues

Symptom

Problem

Solution Refer to

Bent cutterblade Replace blade.

4.4.5 Cutter

blades, page

145

Conditioner roll timing off

Check roll timing , and

adjust if necessary.

3.15.8 Roll Timing, page

88

Excessive noise

Conditioner roll gap

too small

Check roll gap, and adjust

if necess ary.

3.15.6 Roll Gap, page 85

Mud deposits on

conditioner rolls

Clean rolls.

3.18 Unplugging the

Mower Conditioner, page

105

Increase roll gap.

3.15.6 Roll Gap, page 85

Excessive

vibration or noise

in mower conditioner

Conditi

oner rolls

contact

ingeachother

Check roll timing.

3.15.8 Roll Timing, page

88

Excessive heat

in cutterbar

Toomuchoilincutterbar

Drain oil, and refill with

specified amount.

4.4.1 Cutterbar

Lubrication, page 127

Mud on cutterbar

Remov

emudfrom

cutte

rbar. Do not allow

mud t

o dry on cutterbar.

3.18 Unplugging the

Mower Conditioner, page

105

Material wrapped

around spindle

Remove disc and

remove material.

3.18 Unplugging the

Mower Conditioner, page

105

Cut

ting too low in rocky

fiel

d conditions

Decrease mower

conditioner angle.

Increase flotation.

3.1

5.2 Cutterbar Angle,

pag

e82,and

3.1

5.1 Mower Conditioner

Flo

at, page 80

Mower conditioner float

set too heavy

Increase flotation.

3.15.1 Mower Conditioner

Float, page 80

Ground speed too high in

rocky field conditions. At

high ground speed, mower

conditioner tends to dig

rocks from ground instead

of floating over them.

Reduce ground speed.

3.15.4 Ground Speed,

page 84

Blade incorrectly mounted

Check all blade mounting

hardware, and ensure

blades move freely.

4.4.5 Cutterblades, page

145

Frequent blade damage

Bevel-up blades more

susceptible to damage

Switch to

bevel-down blades.

4.4.5 Cutterblades, page

145

147910 256 Revision A

Loading...

Loading...