7 Reference

7.1 Recommended Lubricants

Keep your machine operating at top efficiency by using only clean lubricants and by ensuring the following:

• Use clean containers to handle all lubricants.

• Store lubricants in an area protected from dust, moisture, and other contaminants.

IMPORTAN T:

Do NOT overfi

ll the cutterbar when adding lubricant. Overfilling could result in ov e rh eating and failure of

cutterbar

components.

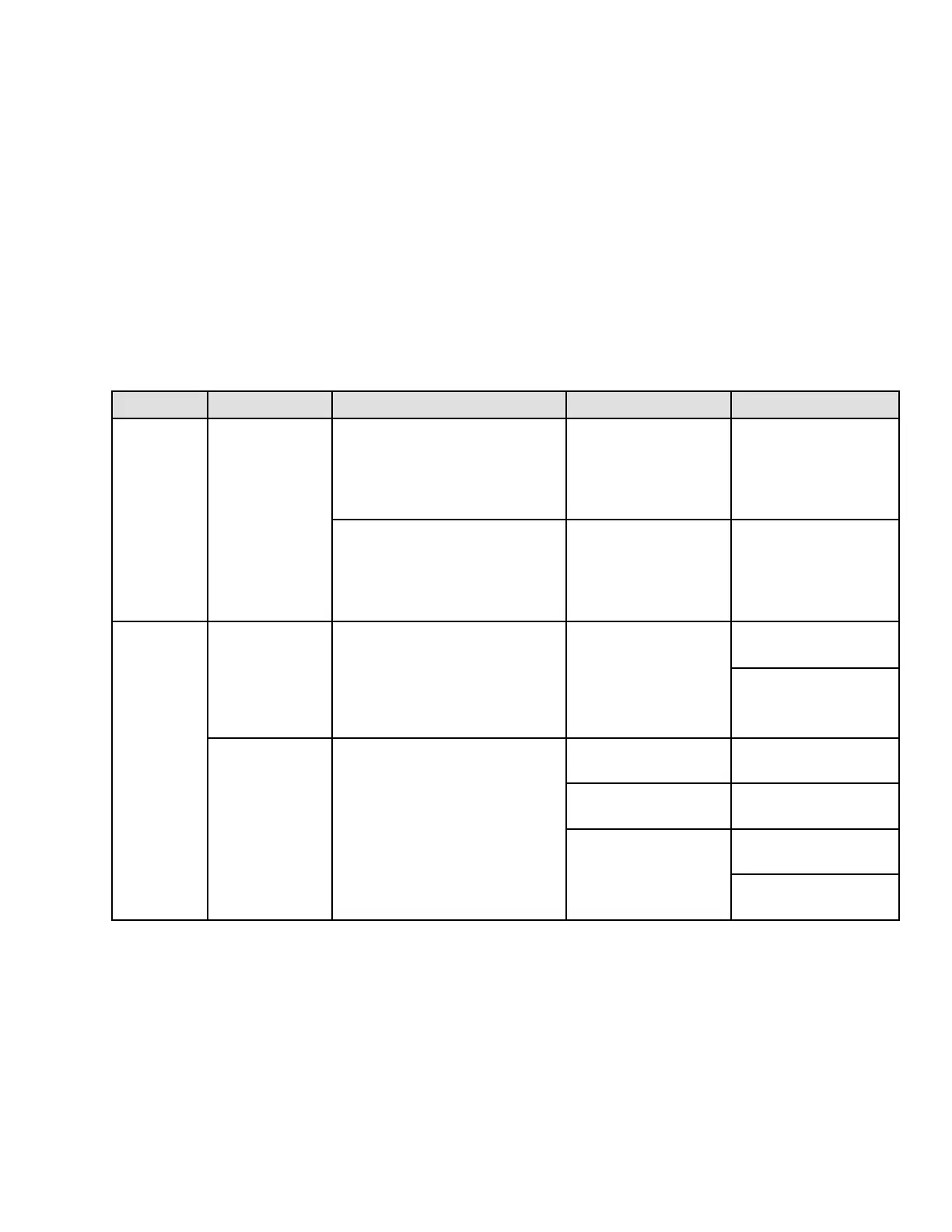

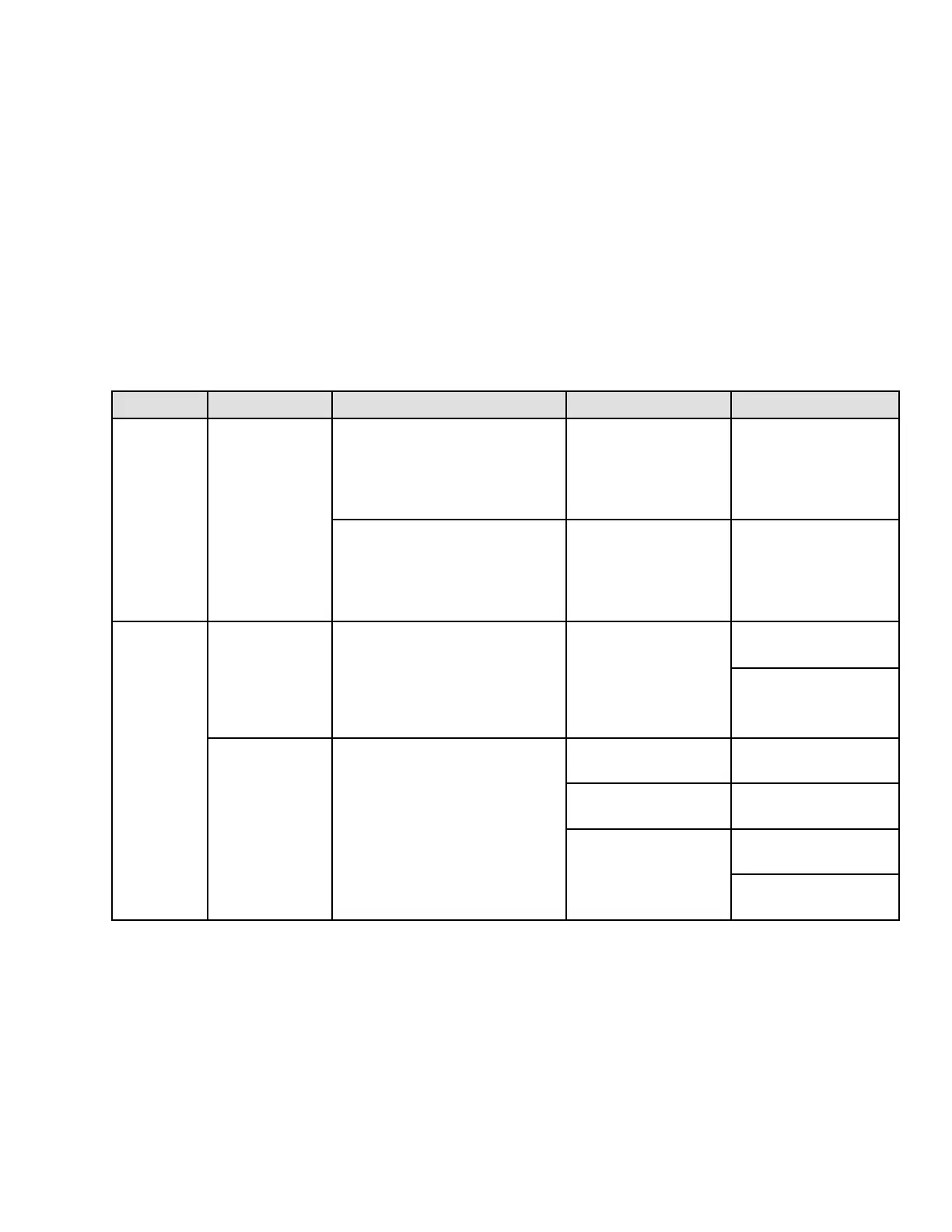

Table 7.1 Recommended Lubricants

Lubricant

Specificat

ion Descr iption Use

Capacitie

s

High temperature extreme

pressure (EP) performance

with 1% max. Molybdenum

Disulphide (NLGI Grade 2)

lithium base

As required unless

otherwise specified

—

Grease

SAE

Multipurpose

High temperature extreme

pressure (EP) performance

with 10% m ax. Molybdenum

Disulphide (NLGI Grade 2)

lithium base

Driveline slip-join ts

—

13-foot: 8.5 qts (US)

(8 liters)

SAE 80W-90

High thermal and

oxidation sta bility

API service class GL-5

Cutterbar

16-foot: 10.5 qts (US)

(10 liters)

Conditioner drive

gearbox

0.75 qts (US)

(0.7 liters)

Mower conditioner

drive gearbox

1.9

qts (US)

(1.

8 liters)

Upper: 1.3 qts (US)

(1.3 liters)

Gear

Lubricant

SAE 85W-140

Gear lubricant API serv ice class

GL-5

Front and rear swivel

gearbox

Lower: 2 qts (US)

(1.9 liters)

147910 259 Revision A

Loading...

Loading...