MAINTENANCE AND SERVICING

4.4.3 Cutterb

ar Spindles

Discs are factory installed to produce a three crop stream, but disc rotation patterns can be changed to suit

crop conditions.

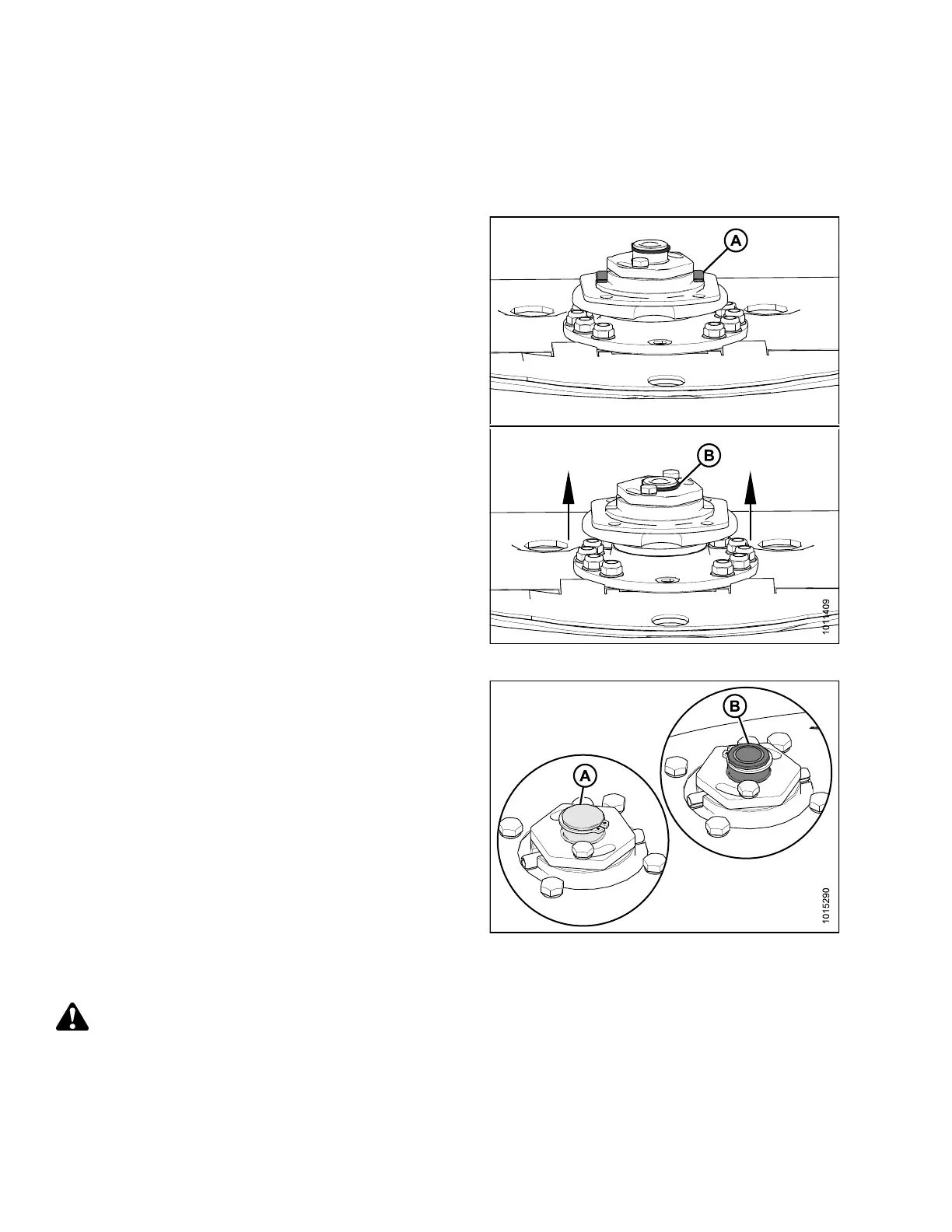

To prevent damage to the cutterbar and drive systems,

each disc is attached to a spindle containing a shear

pin (A). If the disc contacts a large object such as a stone

or stump , the pins will shear and the disc will sto p rotating

and move upwards wh ile remaining attached to the spindle

with a snap ring (B). Refer to 4.4.11 Cutt erba r S pindle

Shear Pin, page 175 to replace shear pin.

Figure 4.29: Cutterbar Spindles

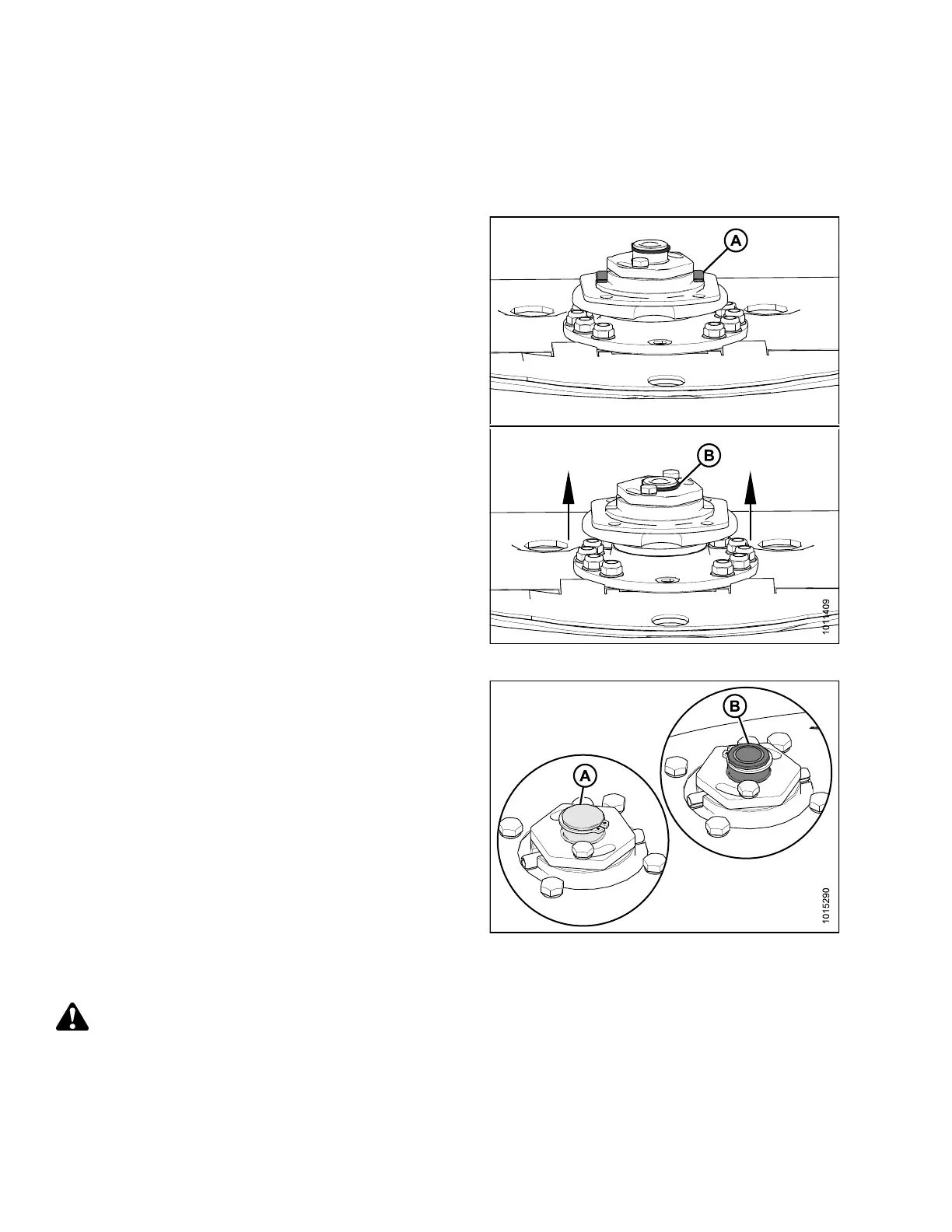

IMPORTANT:

• Spindles that rotate clockwise have

right-handed threading and a smooth top on the

spindle gear shaft (A).

• Spindles that rotate counterclockwise have left-handed

threading and machined grooves on the spindle gear

shaft (B).

Figure 4.30: Cutterbar Spindles

Removing Cutterbar Spindles

DANGER

To avoid bodily injury or death from unexpected start-up or fall of a raised machine, stop engine, remove

key, and engage header lift cylinder lock-out valves before going under machine for any reason.

147910 134 Revision A

Loading...

Loading...