OPERATION

Forming Shields: Finger Conditioner

The position of the forming shields controls the width and placement of the windrow. Deciding which forming shield

position to use is based on the following factors:

• Weather conditions (rain, sun, humidity, wind)

• Type and yield of crop

• Available drying time

• Method of processing (bale s, silage, green-feed)

A wider windrow will generally dry faster and more evenly resulting in less protein loss. Fast drying is especially

important in areas where the weather allows only a few days to cut and bale. For more information, refer to 3.16

Haying Tips, page 102.

A narrower windrow may be preferable for ease of pick-up and when drying is not critical (for example, when cutting

for silage or green-feed).

Positioning Side Deflectors: Finger Conditioner

DANGER

To avoid bodily injury or death from unexpected startup of machine, always stop engine and remove key

from ignition before leaving operator ’s seat for any reason.

The pos ition of the side deflectors controls the width and placement of the windrow. To ensure windrow placement

is center ed with respect to the carrier wheels, adjust both side deflectors to the same position.

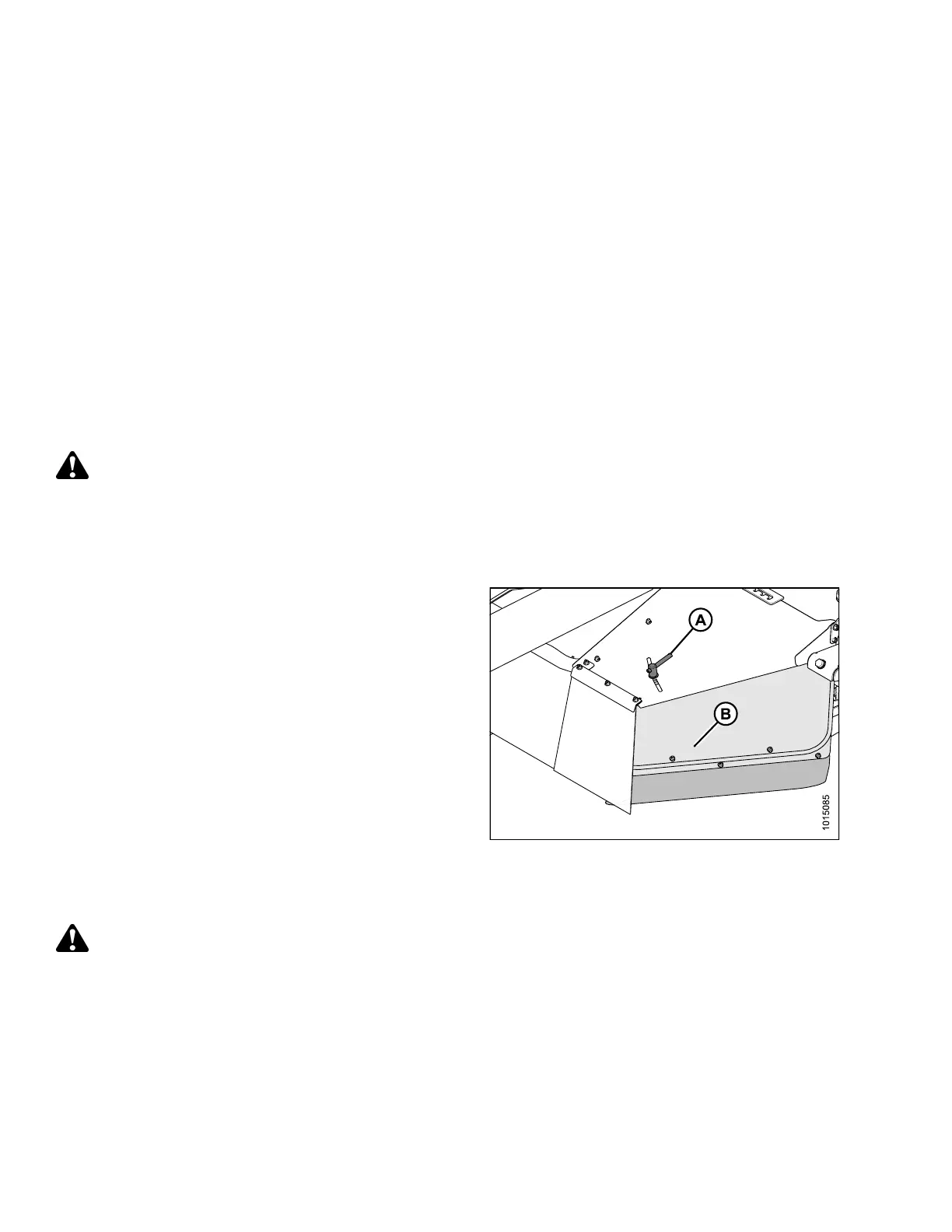

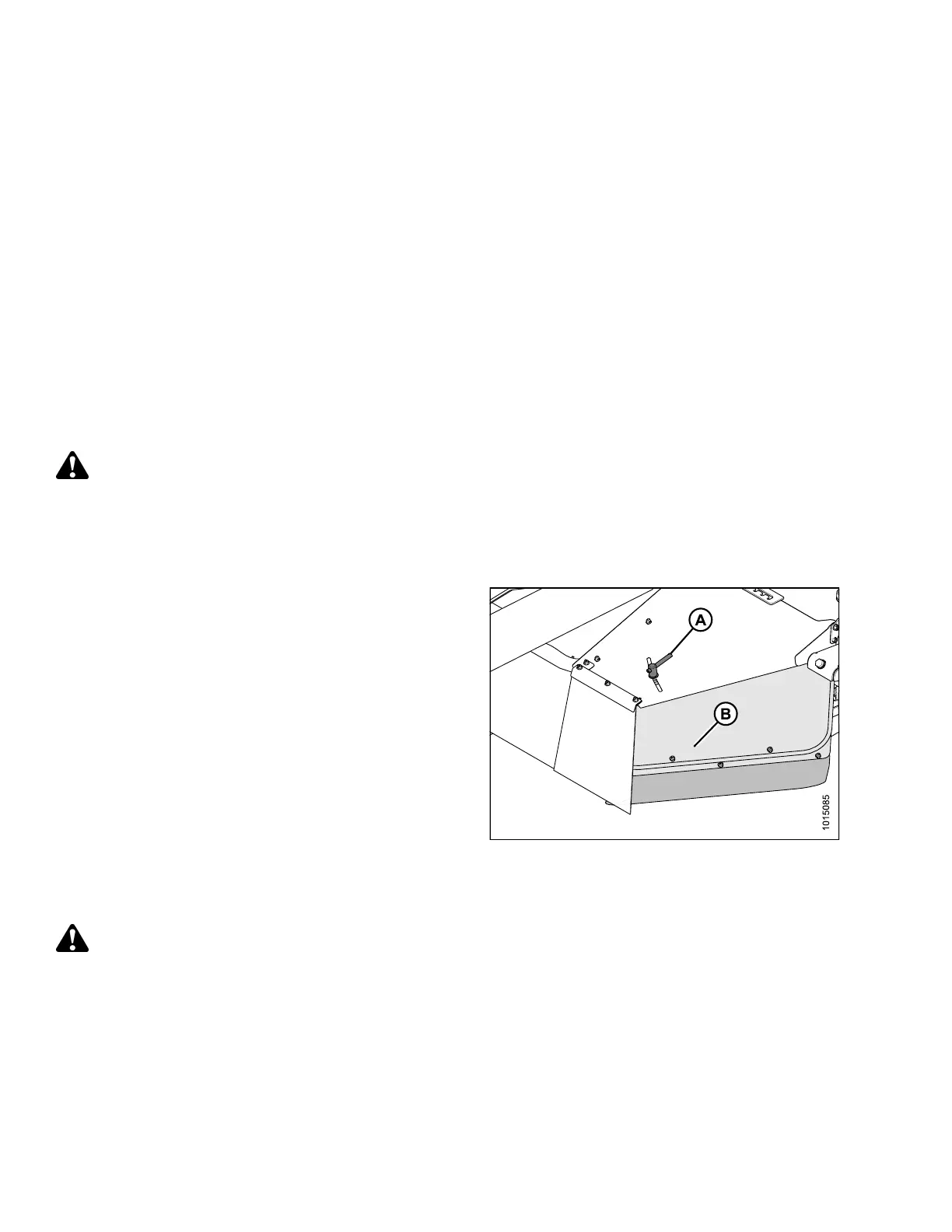

1. Loosen handle (A) on top cover.

2. Move side de flector ( B) to desired position.

3. Tighten the handle.

4. Repeat for other side.

Figure 3.117: Right Side Shown – Left

Side Opposite

Positioning Rear Baffle: Finger Conditioner

DANGER

To avo

id bodily injury or death from unexpected startup of machine, always stop engine and remove key

from i

gnition before leaving operator’s seat for a ny reason.

147910 96 Revision A

Loading...

Loading...