MAINTENANCE AND SERVICING

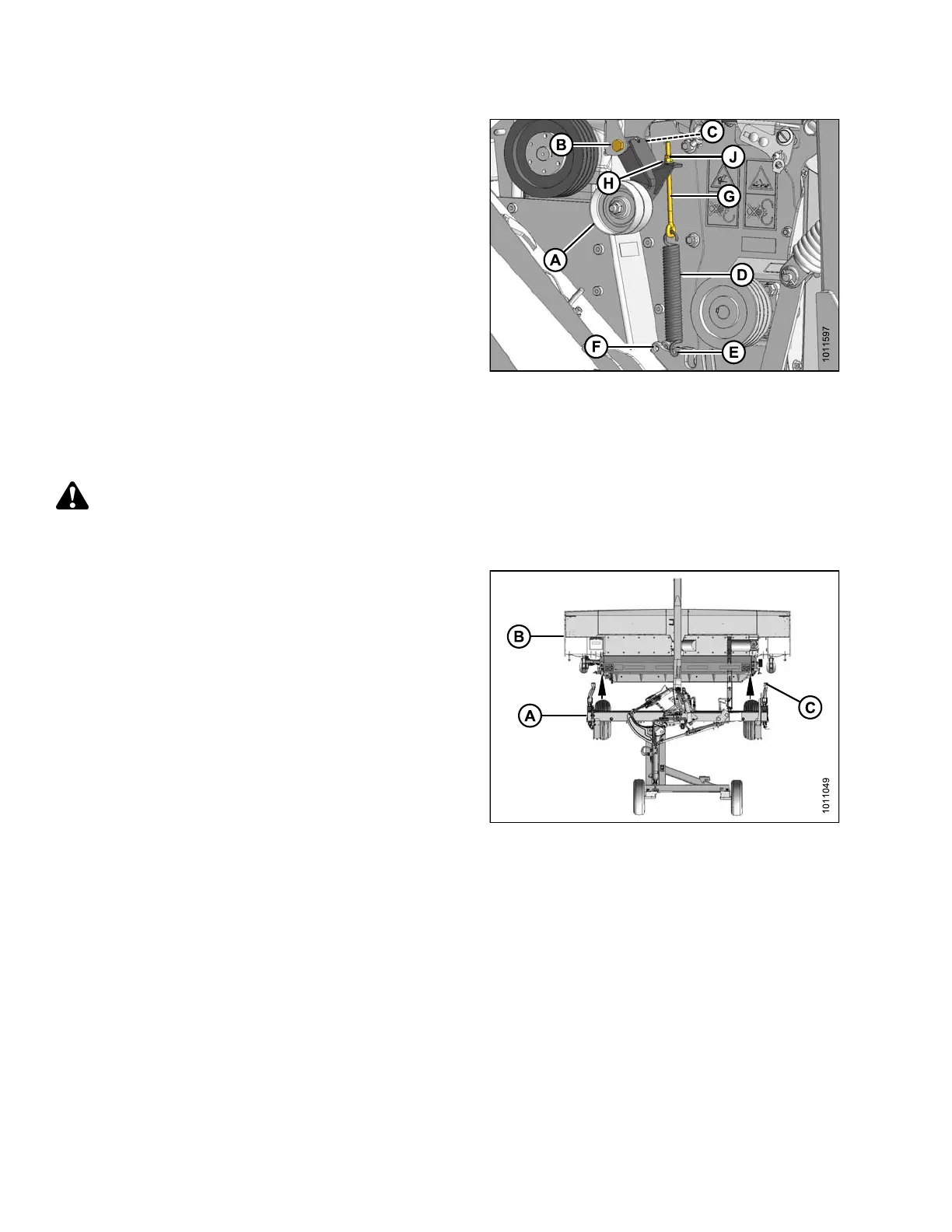

6. Position tensioner assembly (A) as shown and secure

with M16 x 120 bolt (B) and nut (C). Torque nut to

35-40 ft·lbf (47 -54 N·m).

7. Install spring (D) onto frame [rear hole (E) for finger

conditioner, forward hole (F) for roll conditioner].

8. Install eyebolt (G) onto tensioner (A) and spring (D).

Secure eyebolt with hardened washer (H) and two M10

nuts (J).

NOTE:

Conditioner drive belt will be installed after the ca rrier

and header are re-attached.

Figure 4.279: Tensioner

Assembling Header and Carrier

The carri

er must be attached to a tractor for the header and carrier to be assembled.

DANGER

To avoid bodily injury or death from unexpected startup of machine, always stop engine and remove key

from ignition before leaving operator ’s seat for any reason.

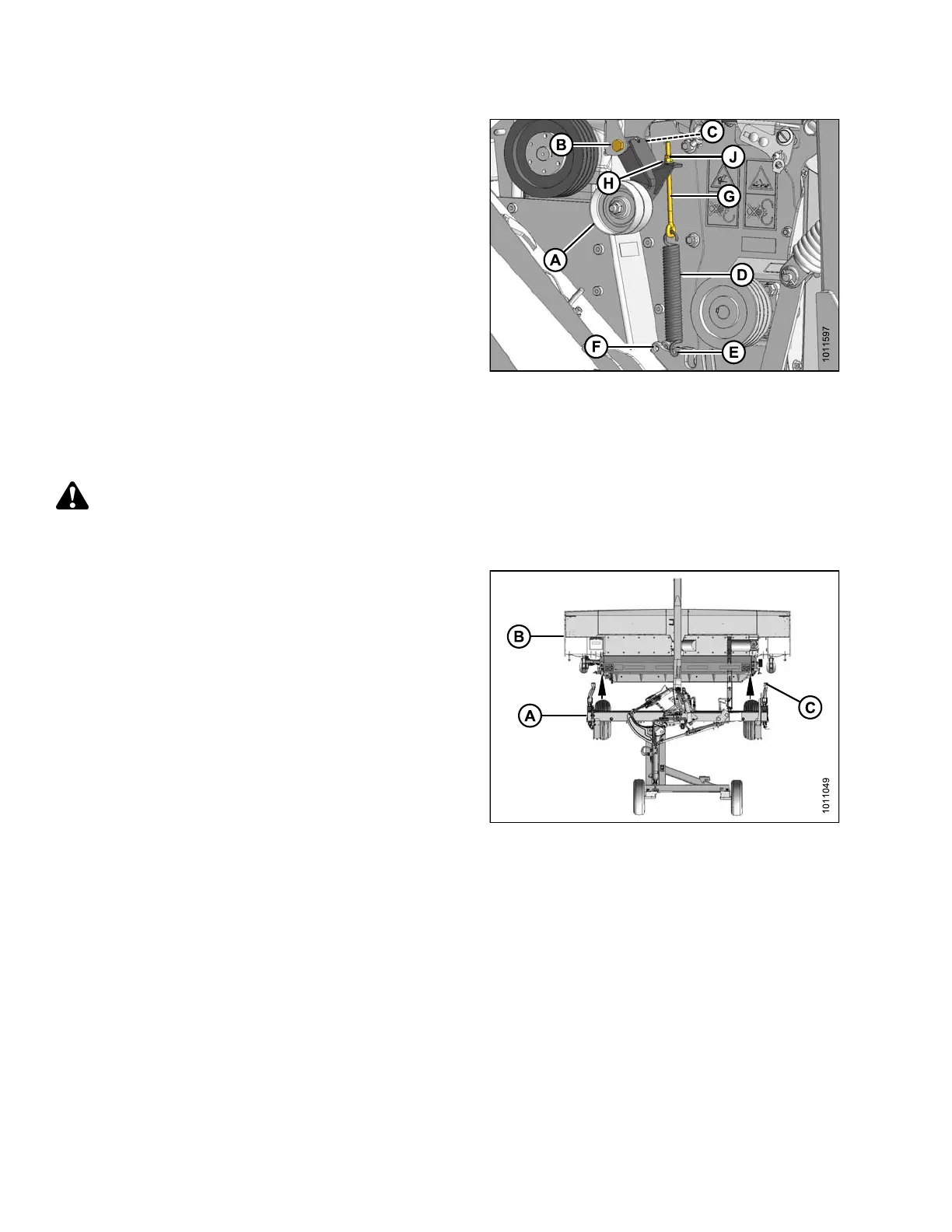

1. Start tractor and maneuver carrier (A) directly behind

the mower conditioner (B) so carrier legs line up with

the header attachment points.

2. Drive slowly forward to engage the carrier legs (C) into

the header attachment brackets.

Figure 4.280: Carrier Aligned with

Mower C onditioner

147910 240 Revision A

Loading...

Loading...