MAINTENANCE AND SERVICING

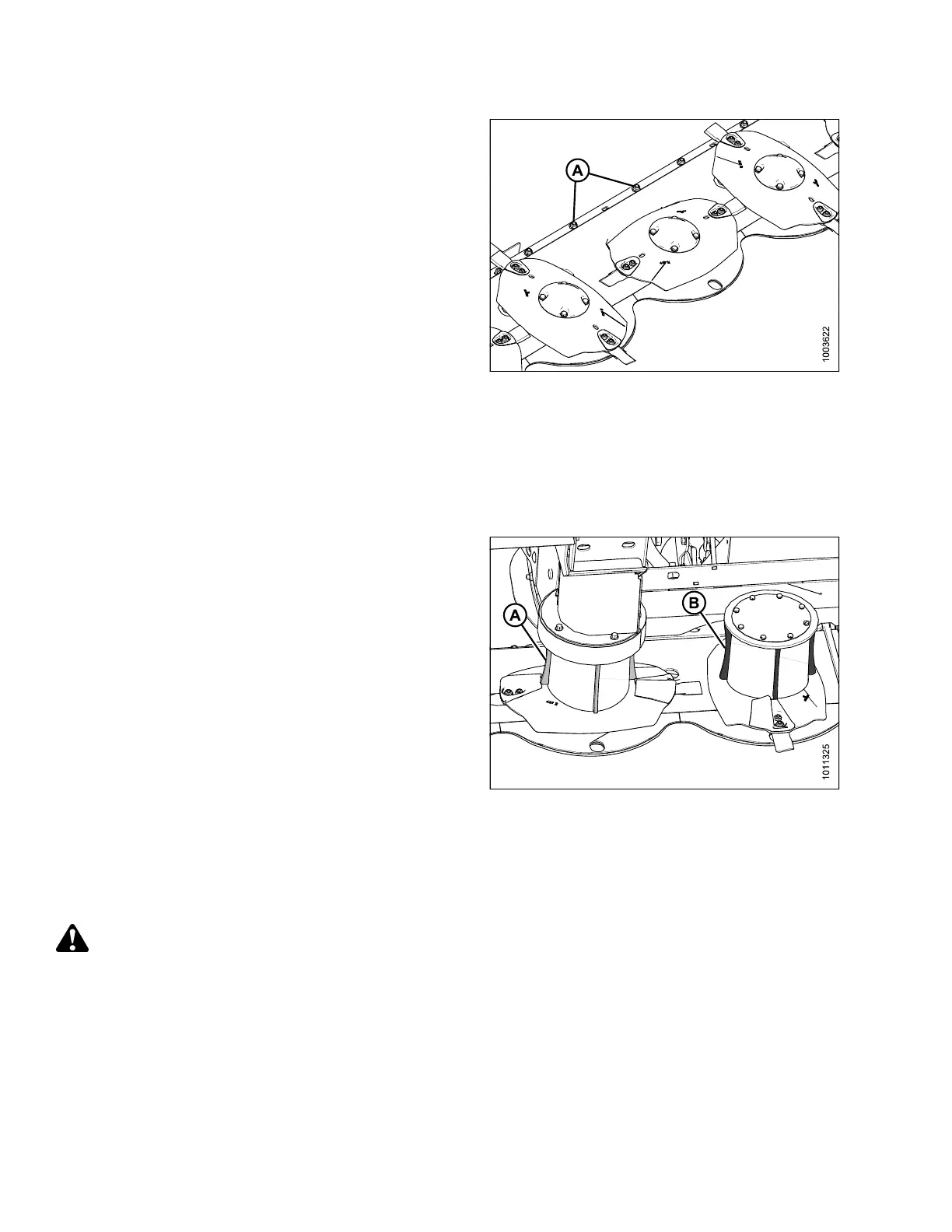

2. Install two hex head screws, w ashers, and lock

nuts (A ). Torque to 50 ft·lbf (68 N·m).

Figure 4.96: Rock Guard Hardware

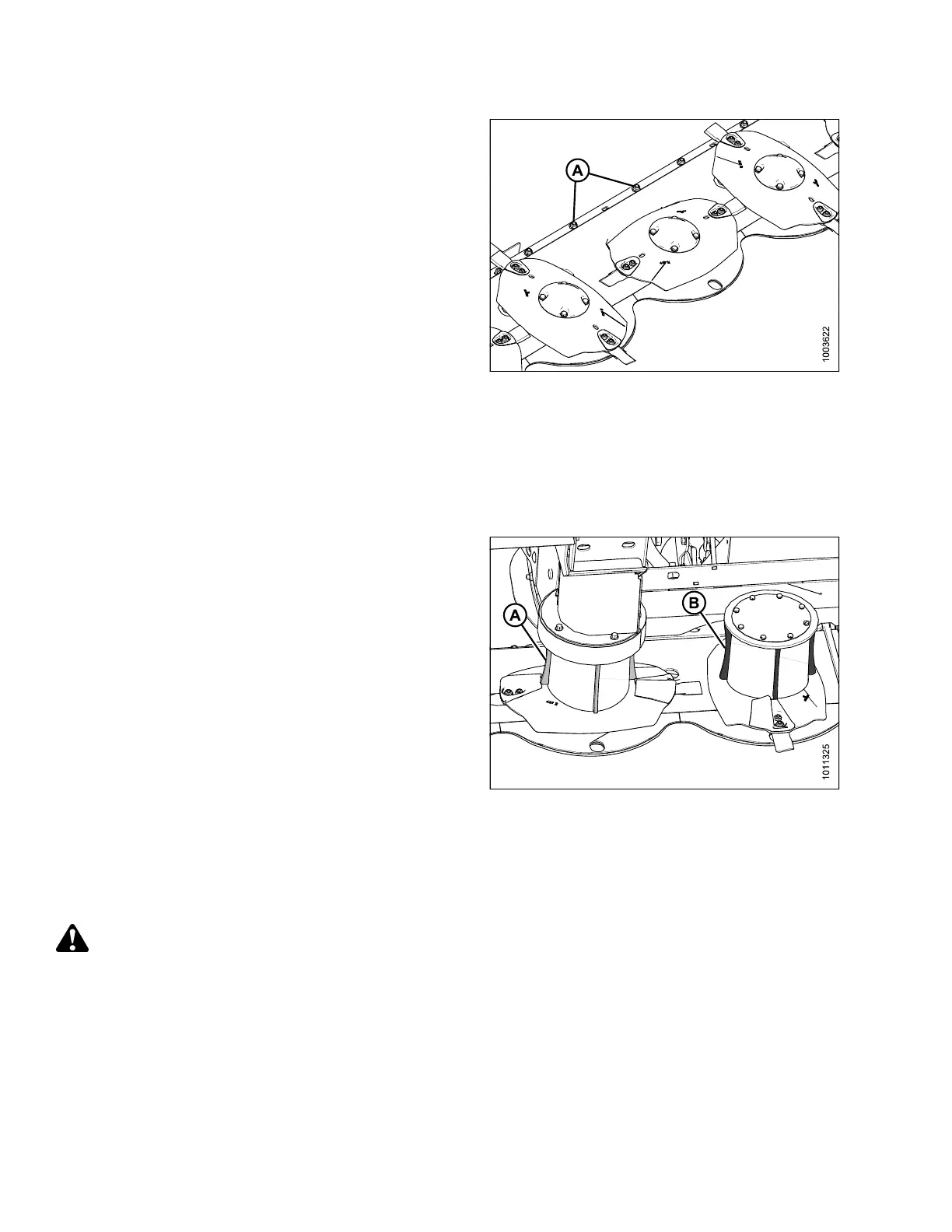

4.4.10 Rotary Deflectors

The rotary deflectors are designed to deliver cut material from the ends of the cutterbar and help maintain an even

flow of crop into the conditioner. Rotary deflectors are attached t o only the two outboard discs at each end of

the cutterbar.

IMPORTAN

T:

The outbo

ard deflectors (B) are approximately

29/32 in.

(23 mm) smaller in diameter than the inboard

deflecto

rs (A).

Figure 4.97: Rotary Deflectors

A - Driven Rotary Deflector B - Non-Driven Rotary Deflector

Inspecting Rotary Deflectors

Inspect rotary deflectors daily for signs of damage or wear.

DANGER

To avoid bodi

ly injury or death from unexpected start-up or fall of a raised machine, stop engine, remove

key, and eng

age header lift cylinder lock-out valves before going under machine for any reason.

147910 164 Revision A

Loading...

Loading...