MAINTENANCE AND SERVICING

NOTE:

It may be necessary to remove and replace the driveline shield cones during the greasing procedure. Refer to

4.5.1 Driveline Shield Cone, page 182 for more information.

NOTE:

Usehightemp

erature extreme pressure (EP2) performance with 10% max molybdenum disulphide

(NLGI Grade 2

) lithium base unless otherwise specified.

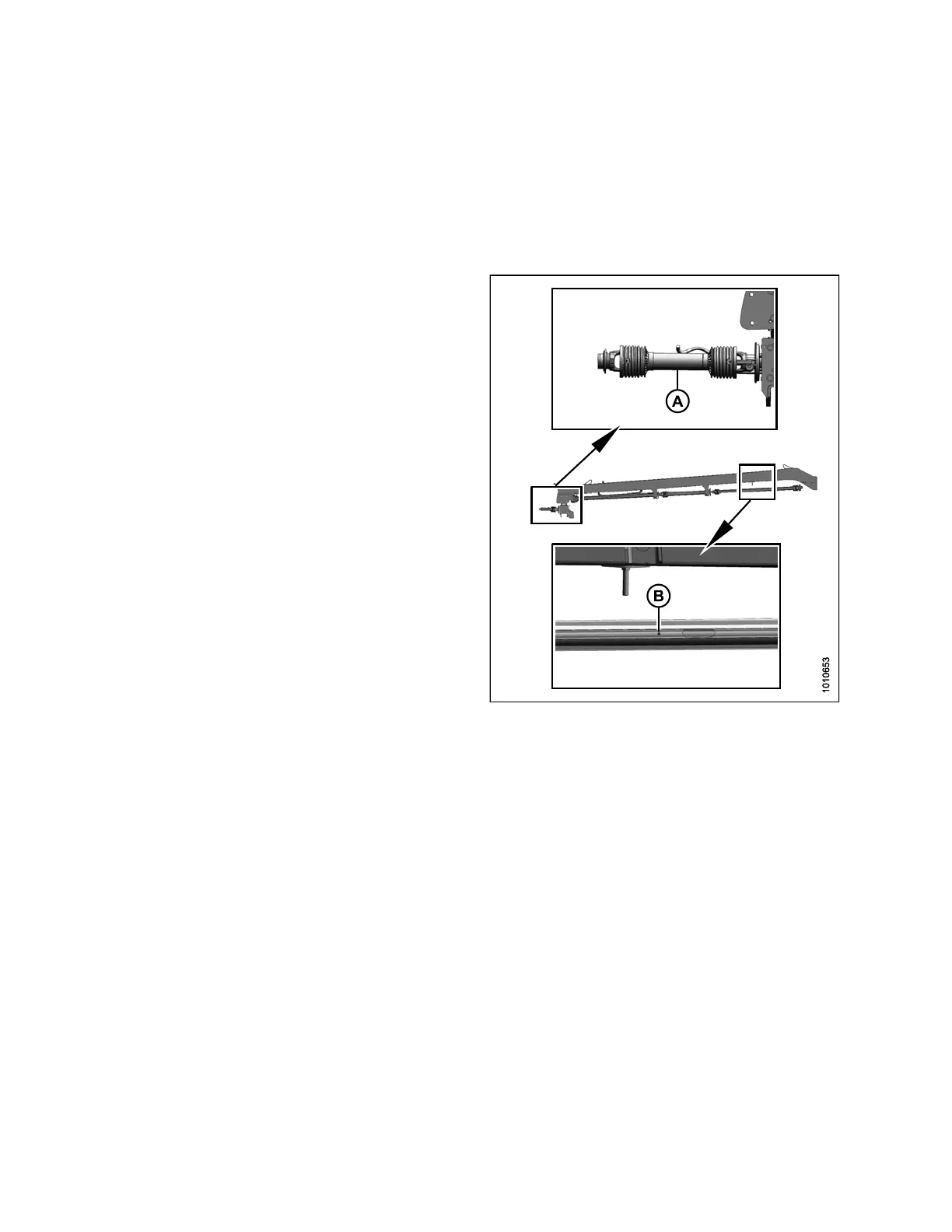

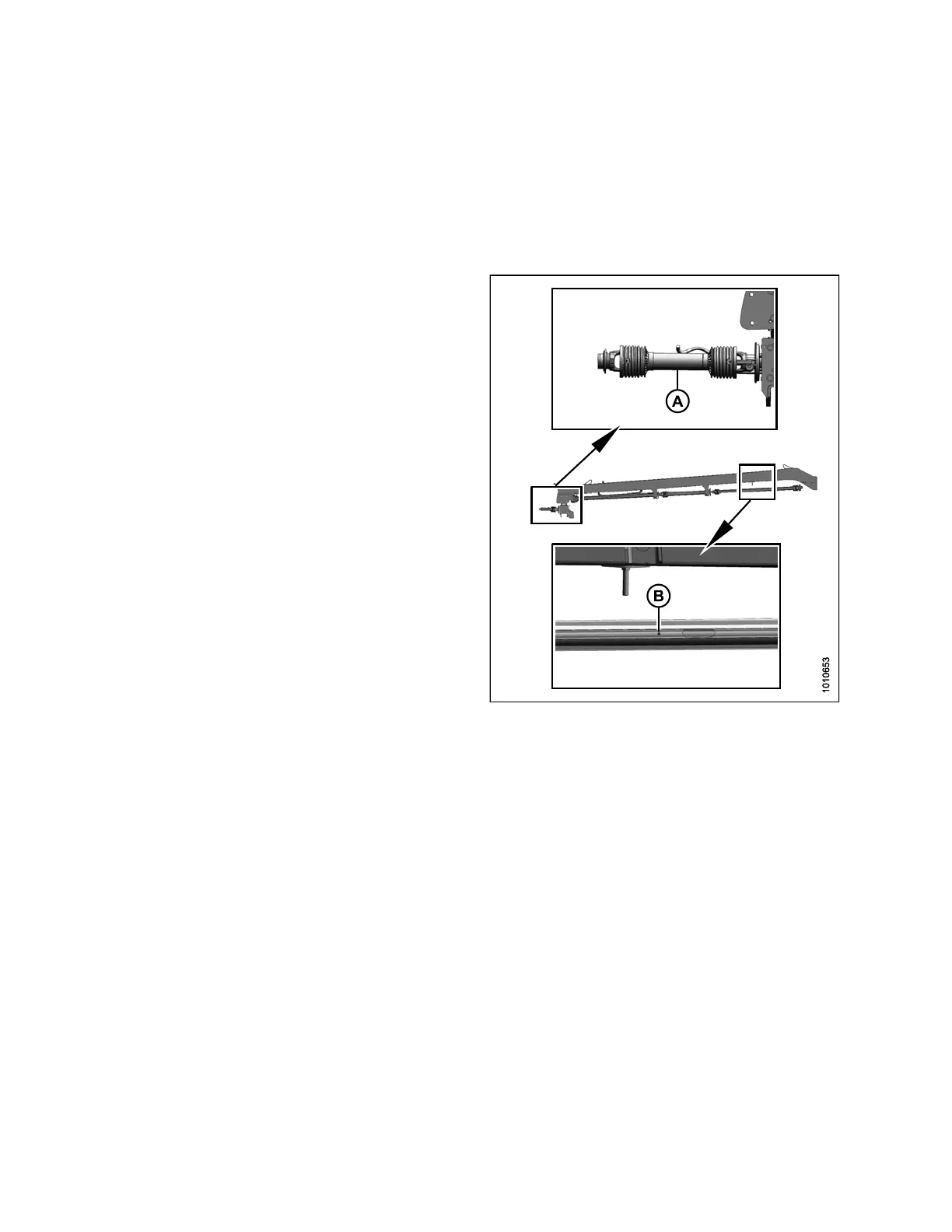

1. Apply grease to driveline slip-joint grease zerks.

Figure 4.9: Every 25 Hours

A - Primary Driveline Slip-Joint B - Driveline Slip-Joint

147910 120 Revision A

Loading...

Loading...