MAINTENANCE AN D SERVICING

1. Place a wooden block between two cutterbar discs to

prevent disc rotation while tightening blade bolts.

IMPORTAN T:

Accelerators

can operate in a clockwise or

counterclock

wise direction. Verify the direction of the

disc before i

nstalling accelerators. If yo u are unsure

which dire ct

ion the spindle rotates, refer to 4.4.3

Cutterbar Sp

indles, page 134

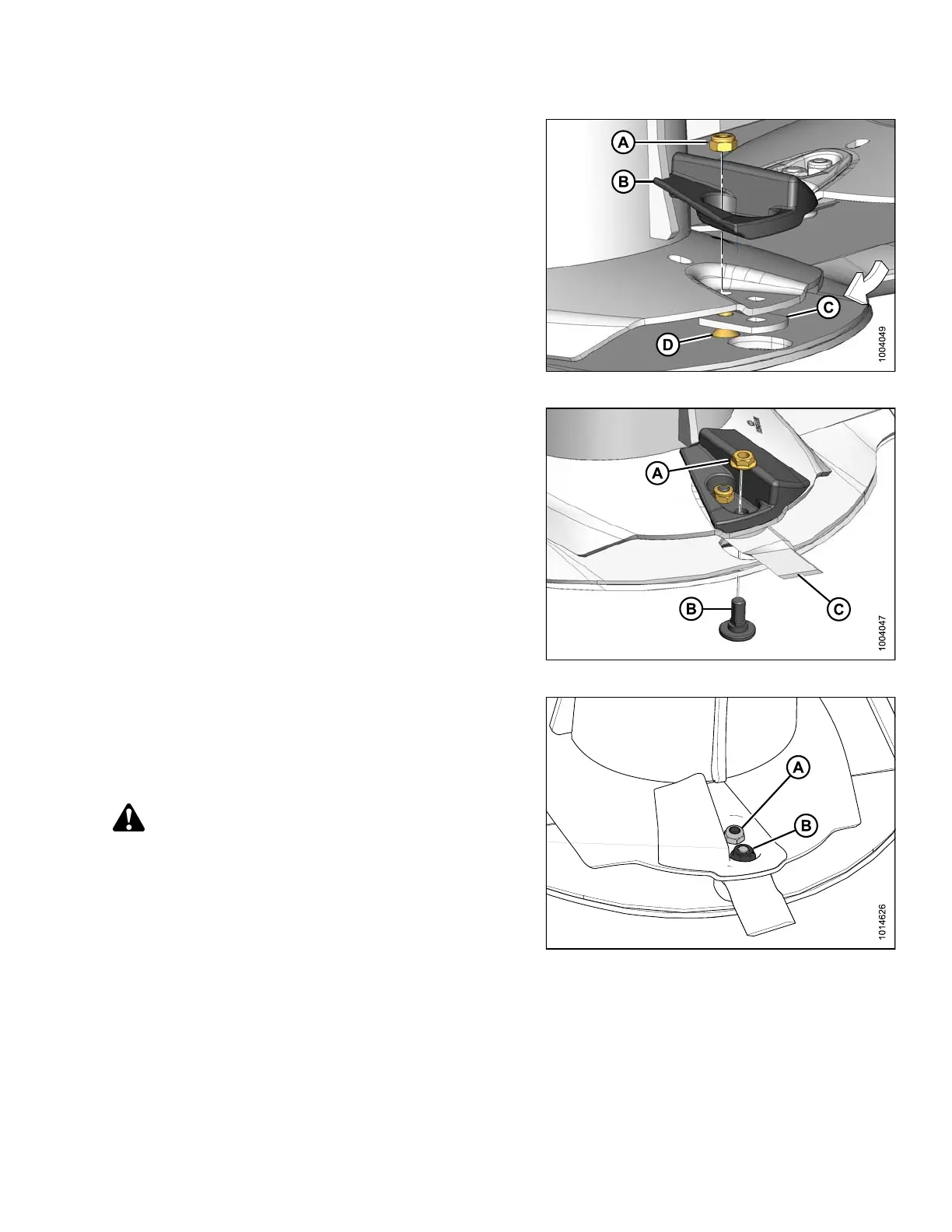

2. Install lock nut (A), accelerator (B), blade holder (C)

andhex-socketbolt(D).DoNOT tighten at this time.

Figure 4.88: Accelerator and Hardware

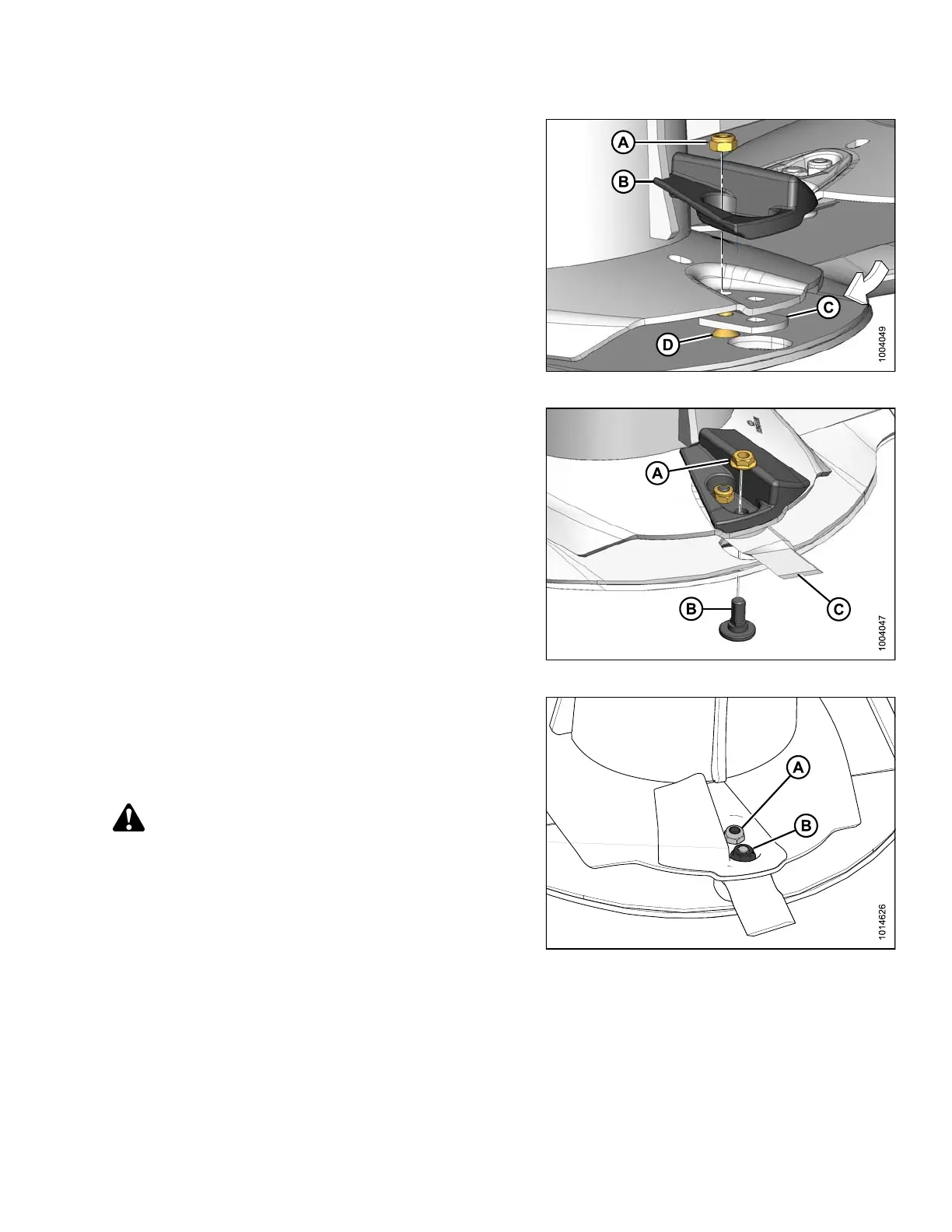

3. Install nu

t(A),flange bolt (B), and cutterblade (C)

onto disc.

Figure 4.89: Cutterblade and Disc

4. Torque

theinsidenut(A)to43ft·lbf (58 N·m).

5. Torqu

e the outside nut (B), closest to the blade, to

92 ft·

lbf (125 N·m).

6. Repea

t the installation procedure for t he second

accel

erator.

WARNING

Ensure cutterbar is completely clear of foreign

objects. Foreign objects can be ejected with

considerable force when the machine is started and

may result in serious injury or machine damage.

Figure 4.90: Cutterblade and Disc

147910 161 Revision A

Loading...

Loading...