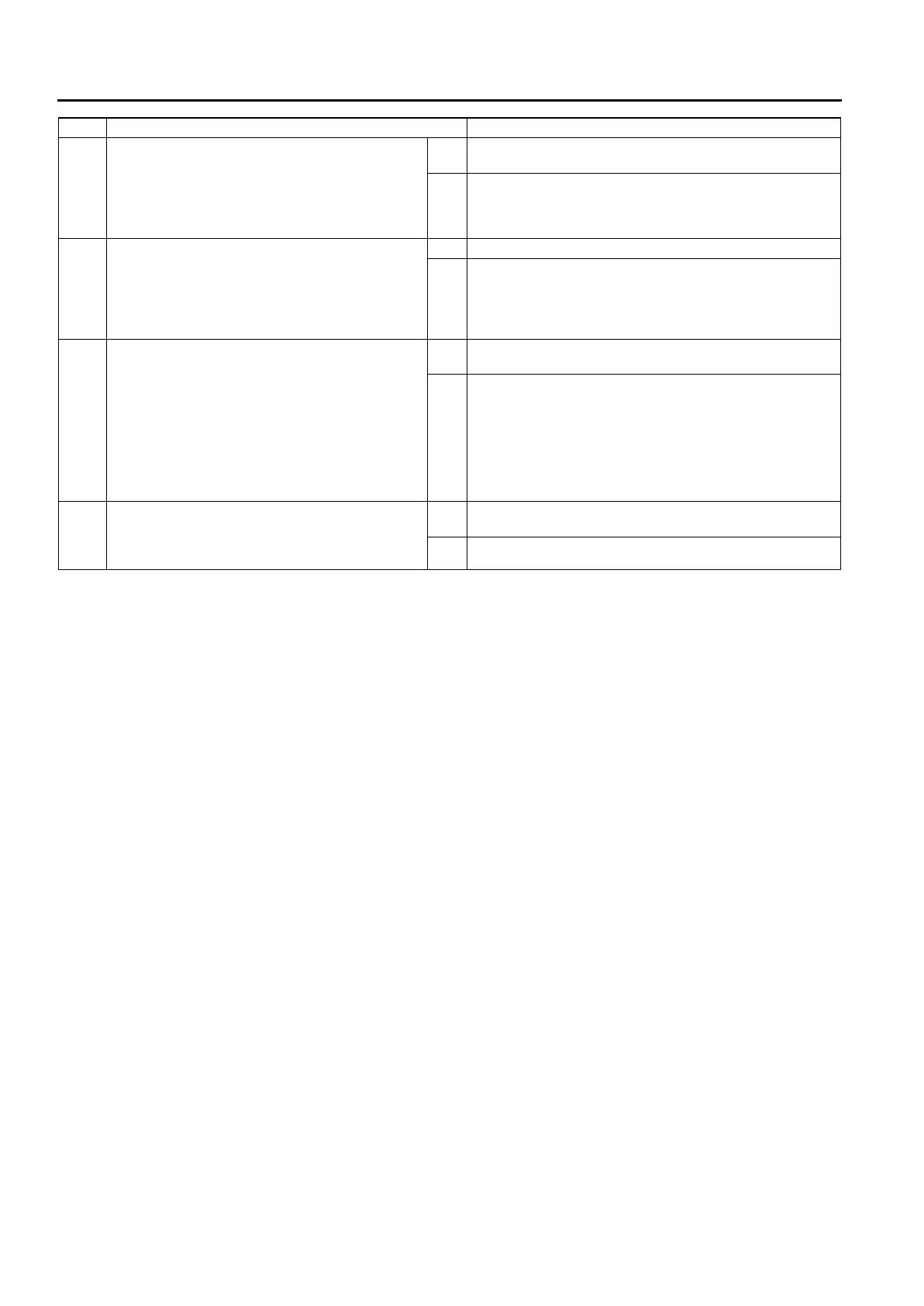

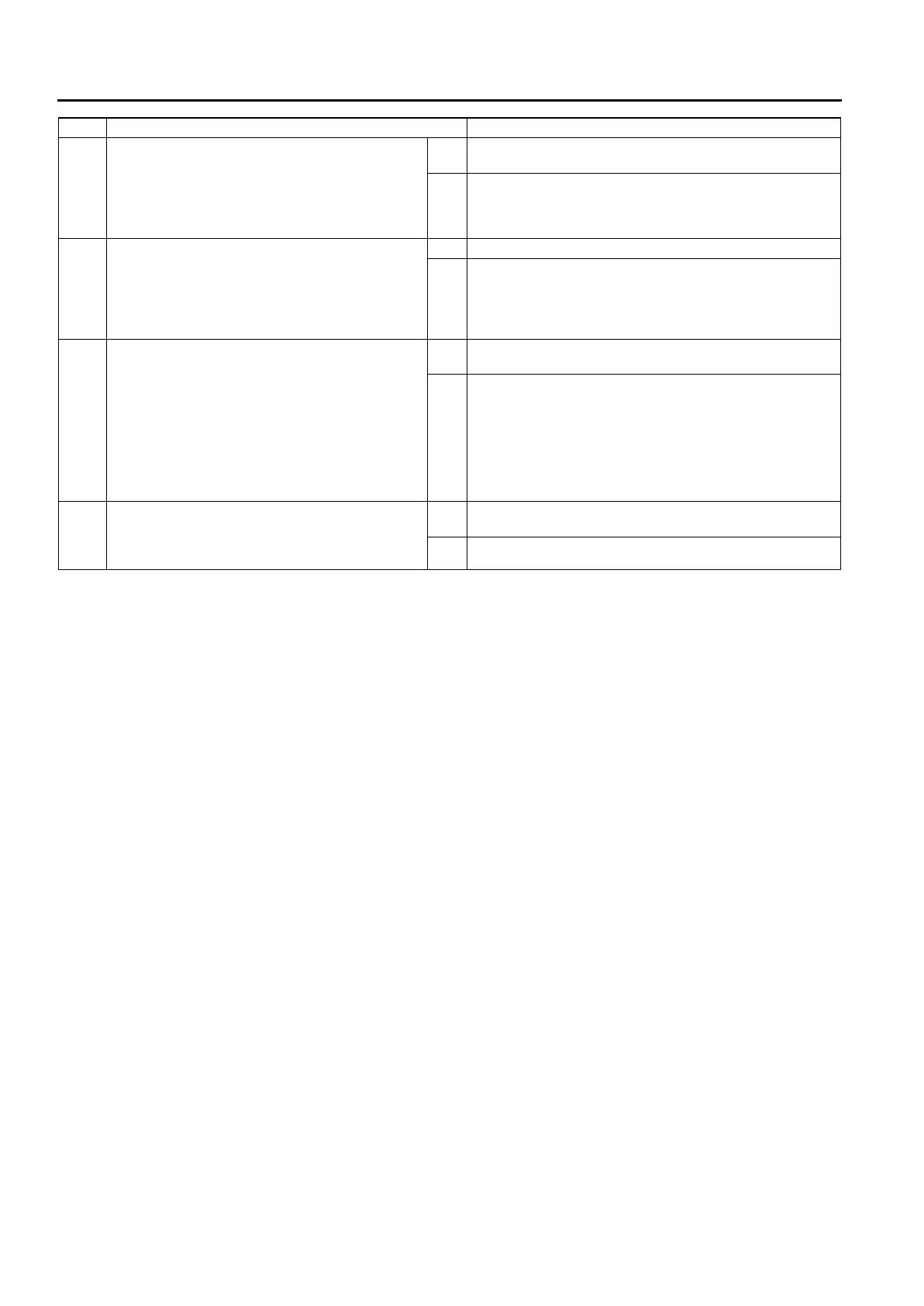

F2–112

ON-BOARD DIAGNOSTIC

End Of Sie

5 INSPECT ECT SENSOR CIRCUIT FOR SHORT

WITH EACH OTHER

• Turn engine switch to OFF.

• Inspect continuity between ECT sensor

terminals A and B.

• Is there continuity?

Yes Repair or replace harness for short with each other, go to

Step 7.

No Go to next step.

6 INSPECT POOR CONNECTION OF PCM

CONNECTOR

• Turn engine switch to OFF.

• Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

• Is there any malfunction?

Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

7 VERIFY TROUBLESHOOTING OF DTC P0117

COMPLETED

• Make sure to reconnect all disconnected

connectors.

• Clear DTC from PCM memory using WDS or

equivalent.

• Perform KOEO/KOER self-test.

(See F2–86 KOEO/KOER SELF-TEST

PROCEDURE)

• Is same DTC present?

Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8 VERIFY AFTER REPAIR PROCEDURE

• Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

• Is there any DTC present?

Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

STEP INSPECTION ACTION

Loading...

Loading...