AUTOMATIC TRANSAXLE

K2–59

K2

Operation

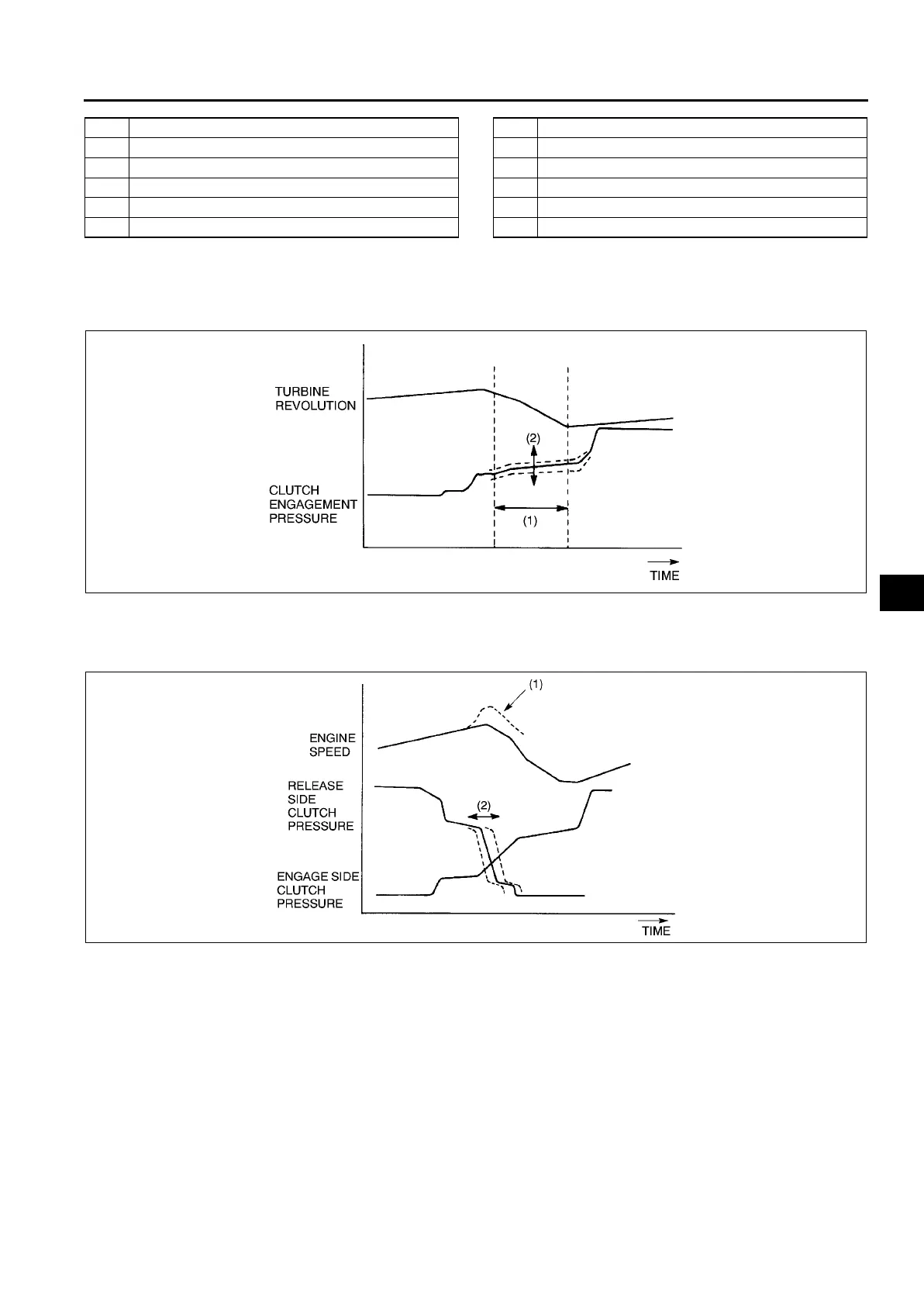

Upshift clutch engagement pressure feedback

• Clutch pressure (2) is learned so that gear shift time (1) becomes a predetermined target value, and thus

changes in performance and changes in the transaxle over time are minimized based on past gear shift results.

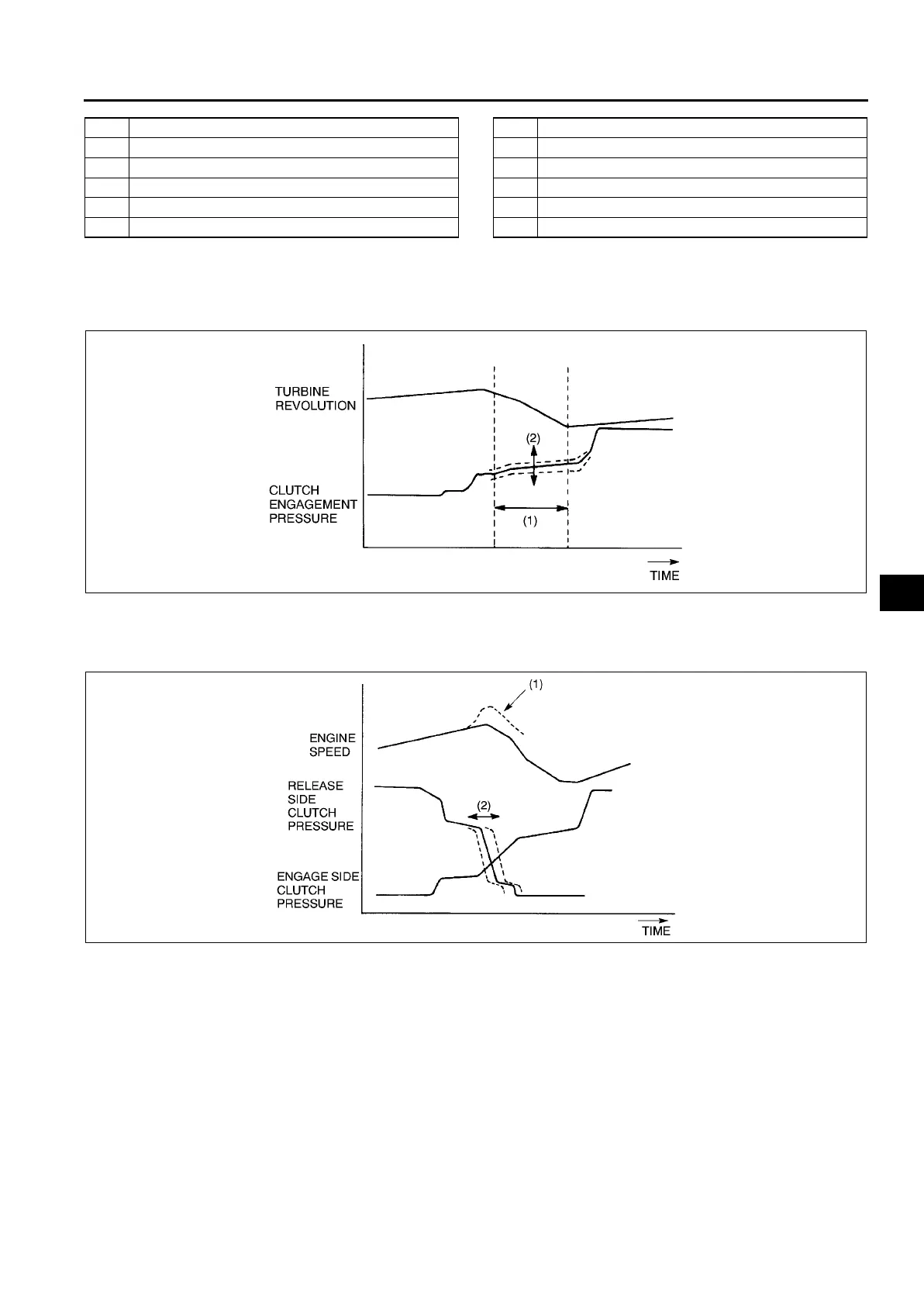

Upshift timing feedback (release-side clutch pressure)

• Clutch pressure release timing on the release side (2) is learned so that the change in engine speed (1) is

optimized, and thus clutch pressures on the engagement and release sides are optimized.

End Of Sie

N-D SELECT CONTROL DESCRIPTION

A6E571418901207

• When the selector lever is switched from the P or N position to the driving ranges, or vice versa, the engine

speed change is minimized by regulating fuel injection volume in order to improve select feel.

• Range signals are output to the PCM in the following instances:

When the selector lever is switched from the P or N position to the driving ranges, or vice versa, and the

specified time has elapsed.

• The PCM regulates fuel injection volume based on inhibitor signals prevent change in engine speed.

End Of Sie

TORQUE CONVERTER CLUTCH (TCC) CONTROL DESCRIPTION

A6E571418901208

Outline

Features

• The TCM selects the TCC schedule according to the gear selected by the transaxle. 50 Hz (20 ms cycle) on/off

signals are relayed from the TCC schedule and speed sensor and throttle opening angle to the duty cycle TCC

solenoid valve to control TCC.

8PCM

9 TFT sensor

10 TCM

11 TR switch

12 Pressure control solenoid

13 2-4 brake solenoid valve

14 High clutch solenoid valve

15 GND return

16 R

17 D

18 N

19 P

AMU0517S038

AMU0517S039

Loading...

Loading...