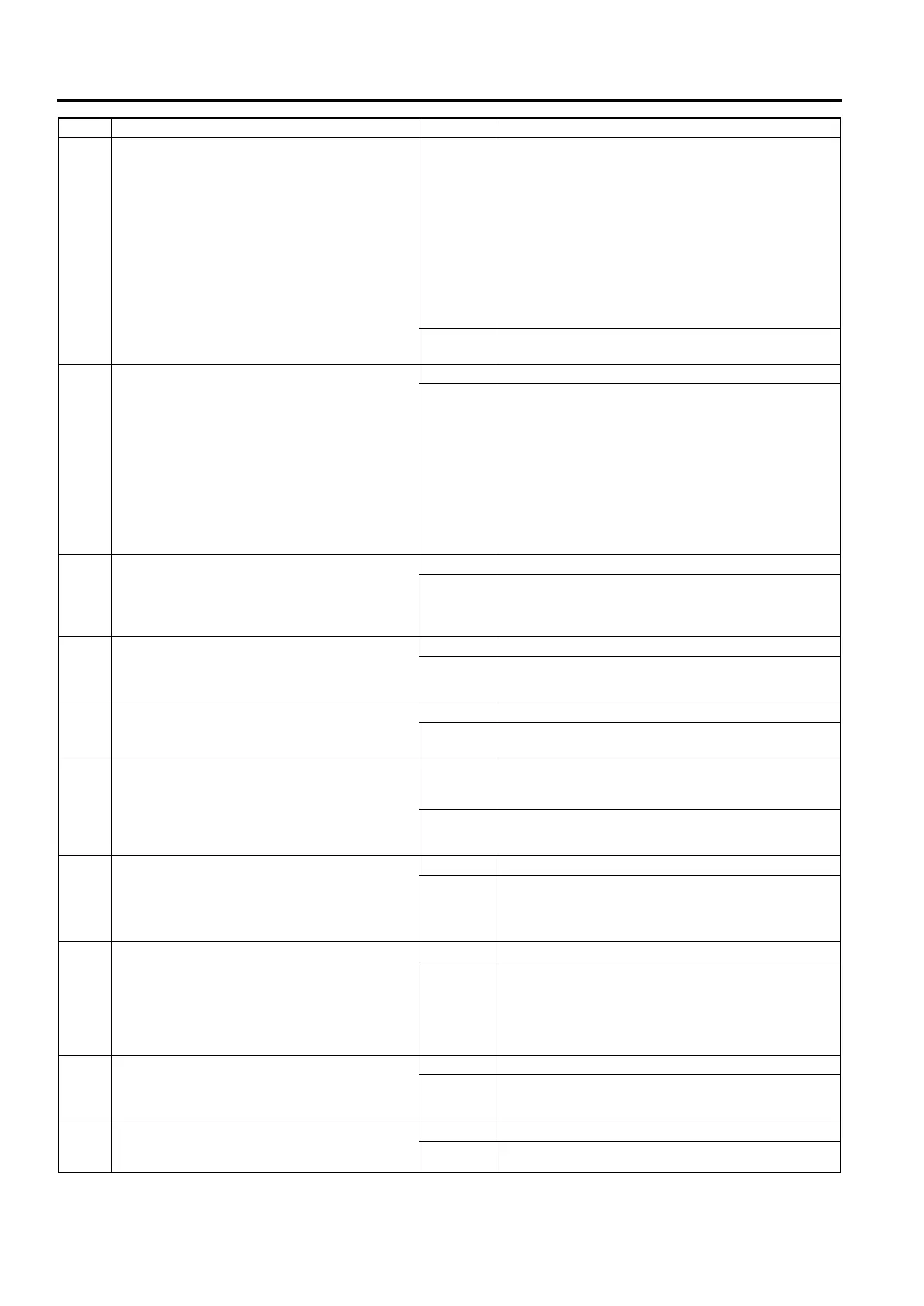

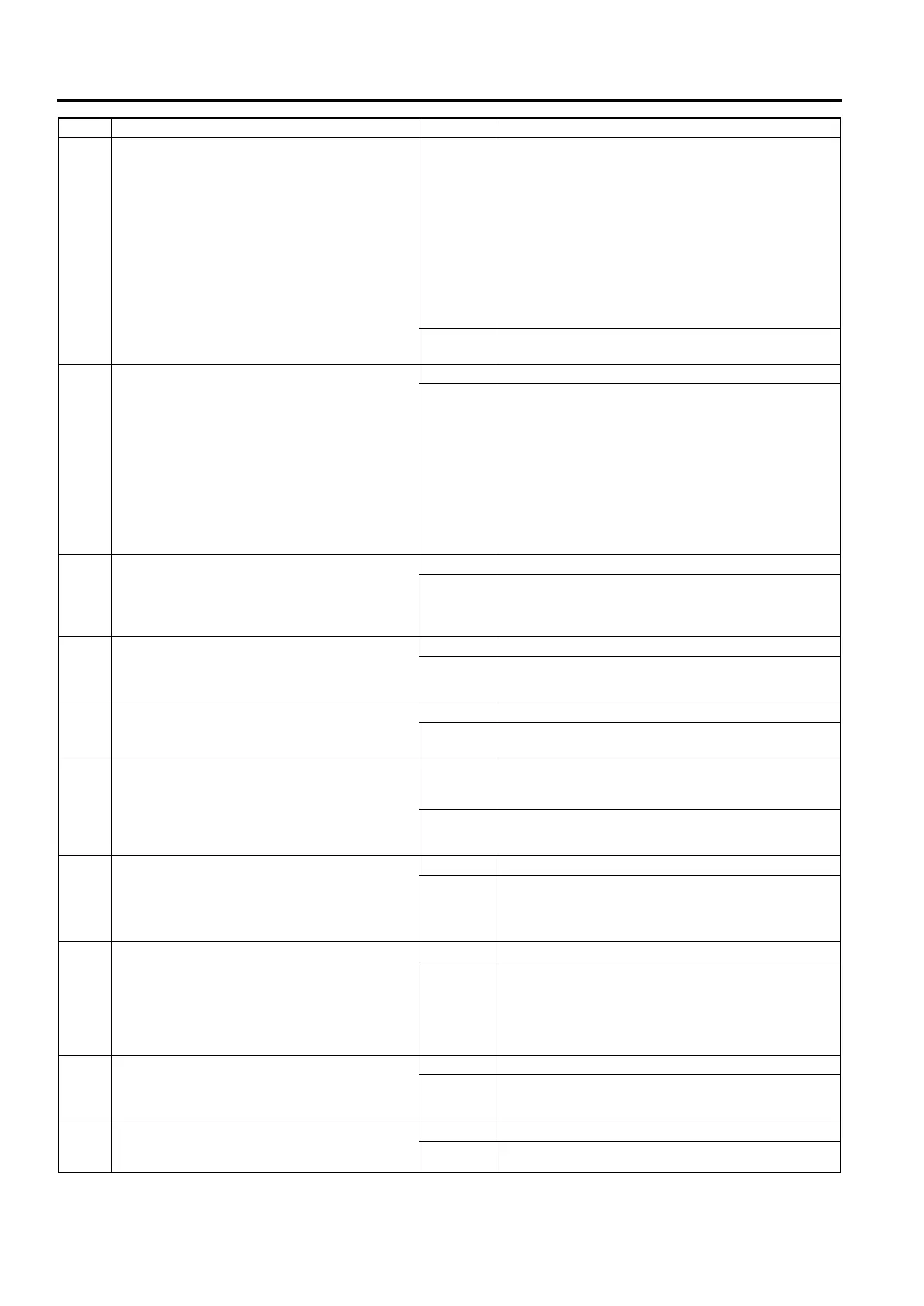

F2–196

TROUBLESHOOTING

3 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?

Yes DTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

• Open circuit between PCM control relay and PCM

terminal 53 or 79

• Open circuit PCM control relay and PCM terminal

69

• PCM control relay stuck open

• Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

• Poor connection vehicle body GND

No No DTC is displayed:

Go to next step.

4 Inspect for following:

• Fuel quality (e.g.: including water

contamination, winter/summer blend)

• Fuel line/fuel filter clogging and/or restriction

• Intake-air system restriction

• Exhaust system and/or catalyst converter

restriction

• Charge air cooler condition (restriction or

damaged)

• Vacuum leakage

• Cooling fan No.1 and cooling fan No.2 seat

Are all items okay?

Yes Go to next step.

No Service as necessary.

Repeat Step 4.

5 Inspect intake shutter valve and VSC valve

operations.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is there any problem?

Yes Repair or replace as necessary.

No Go to next step.

6 Inspect guide blade valve operation.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is there any problem?

Yes Repair or replace as necessary.

No Go to next step.

7 Inspect A/C cut-off operation.

Does A/C cut-off work properly?

Yes Go to next step.

No Repair or replace malfunctioning part according to A/C

cut-off system inspection results.

8 Inspect hose bands between following parts:

• Turbocharger compressor housing and air

cleaner

• Turbocharger compressor housing and

charge air cooler

Are hose bands loose?

Yes Retighten hose bands.

If concern is resolved, complete inspection.

If concern still exists, go to next step.

No Go to next step.

9 Inspect for improper operation, kinks, clogging or

disconnection on guide blade actuator.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is actuator okay?

Yes Go to next step.

No Repair or replace as necessary.

If concern is resolved, complete inspection.

If concern still exists, turbocharger is okay.

Go to next step.

10 Remove parts necessary to inspect

turbocharger.

Do not remove turbocharger.

Inspect if turbocharger compressor wheel is

bent, damaged, or interfering with housing on

vehicle.

Is there any problem?

Yes Replace turbocharger.

No Go to next step.

11 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?

Yes Replace turbocharger.

No Go to next step.

12 Inspect if turbocharger compressor wheel by

hand.

Does wheel turn easily and smoothly?

Yes Go to next step.

No Replace turbocharger.

STEP INSPECTION RESULTS ACTION

Loading...

Loading...