ON-BOARD DIAGNOSTIC

F2–111

F2

DTC P0117

A6E407001082214

Diagnostic procedure

DTC P0117 ECT sensor circuit low input

DETECTION

CONDITION

• PCM monitors input voltage from ECT sensor while engine is running. If input voltage from ECT sensor is

below 0.1 V, PCM determines ECT sensor circuit low input.

POSSIBLE

CAUSE

• ECT sensor malfunction

• Connector or terminal malfunction

• Short to GND in wiring between ECT sensor terminal A and PCM terminal 87

• ECT sensor signal and GND circuits short each other

• PCM malfunction

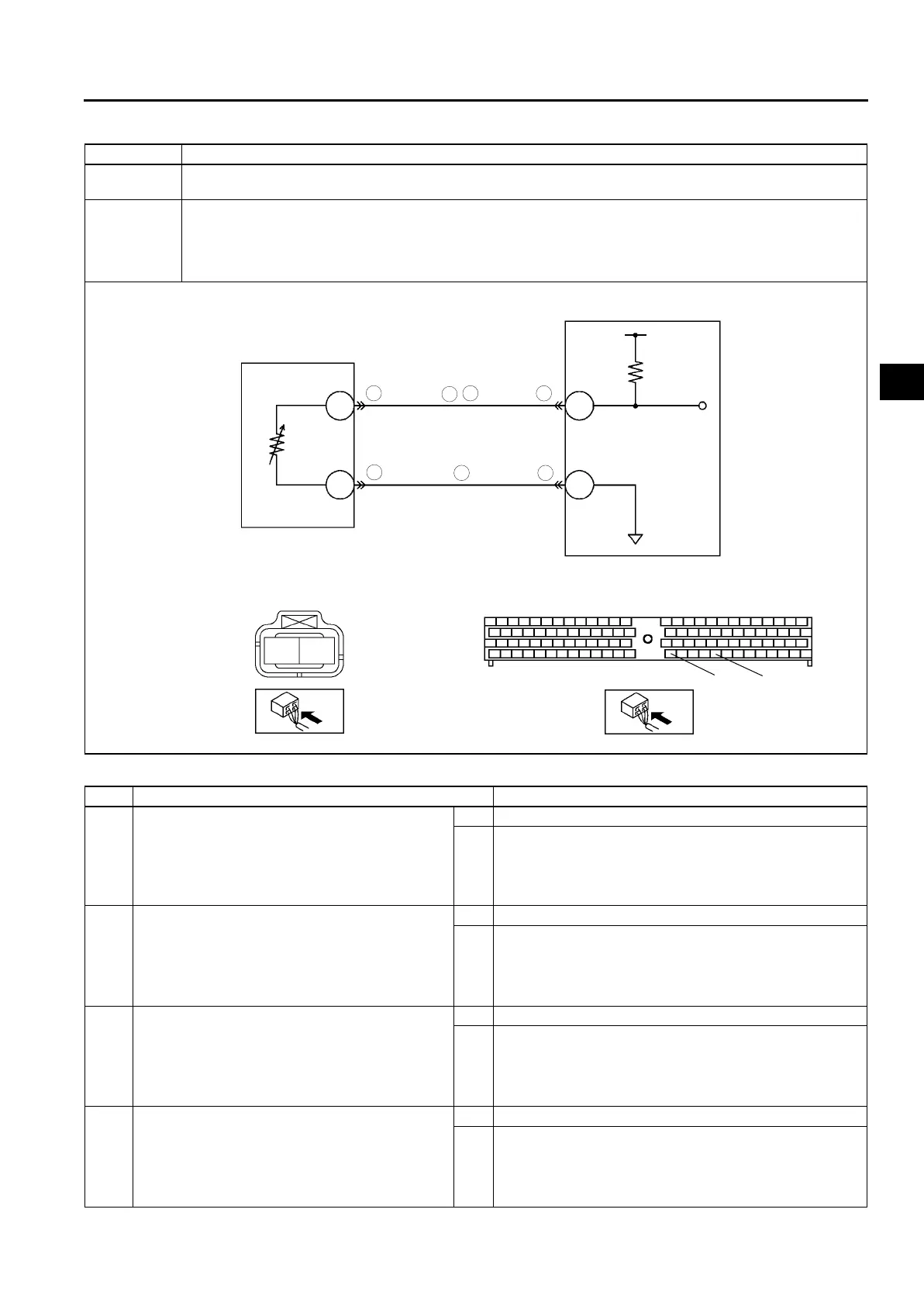

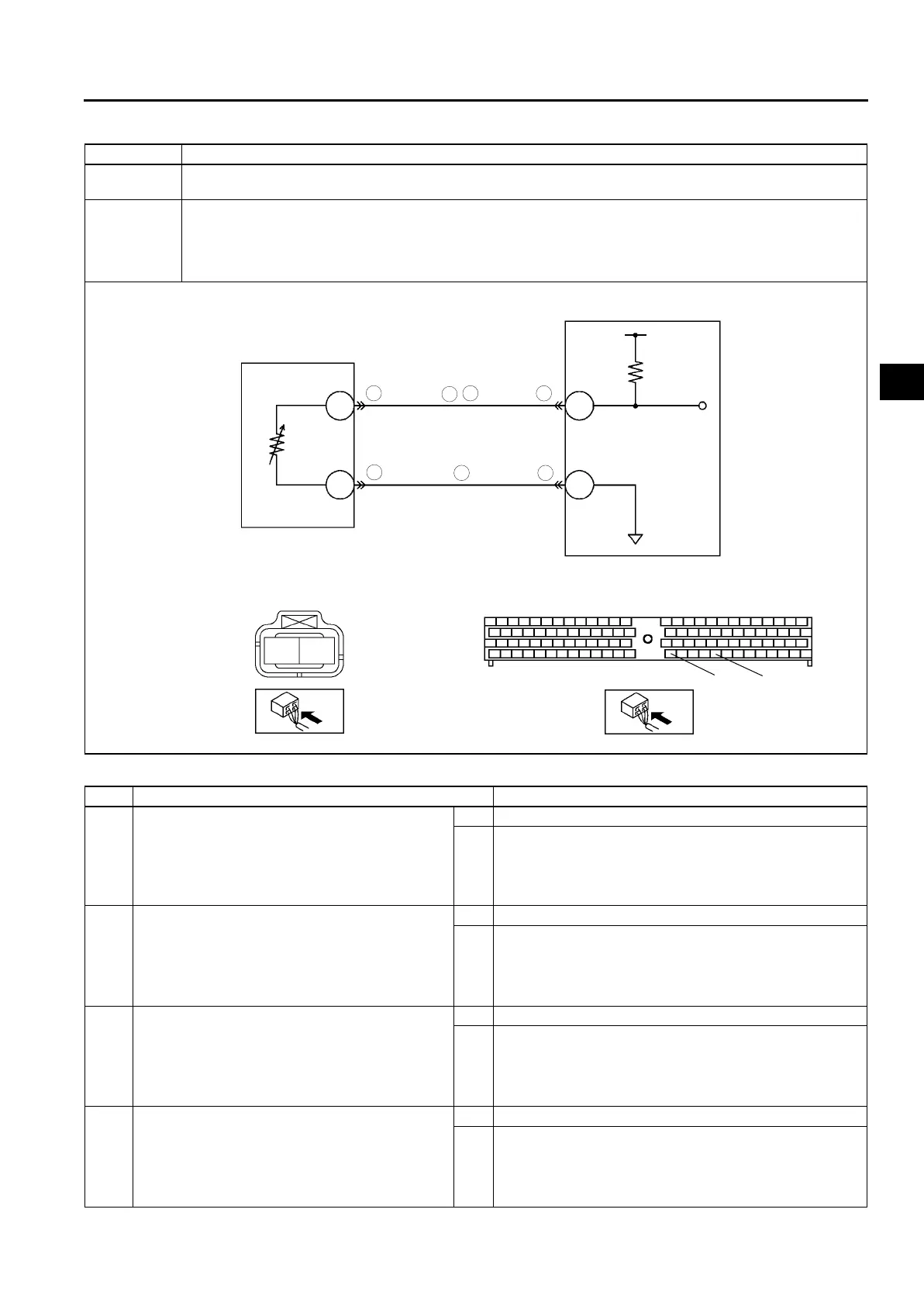

ECT SENSOR

A

B

5 6

2

5

4

6

2

87

91

B

A

PCM

91

87

ECT SENSOR

HARNESS SIDE CONNECTOR

PCM

HARNESS SIDE CONNECTOR

STEP INSPECTION ACTION

1 PERFORM DTC CONFIRMATION PROCEDURE

• Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

• Is same DTC present during KOEO or KOER

self-test?

Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2 INSPECT POOR CONNECTION OF ECT

SENSOR CONNECTOR

• Turn engine switch to OFF.

• Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

• Is there any malfunction?

Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3 CLASSIFY ECT SENSOR MALFUNCTION OR

HARNESS MALFUNCTION

• Turn engine switch to ON (Engine OFF).

• Disconnect ECT sensor connector.

• Access ECT PID using WDS or equivalent.

• Is ECT PID below 0.1 V?

Yes Go to next step.

No Replace ECT sensor, go to Step 7.

(See F2–76 ENGINE COOLANT TEMPERATURE (ECT)

SENSOR REMOVAL/INSTALLATION)

4 INSPECT ECT SENSOR SIGNAL CIRCUIT FOR

SHORT TO GND

• Turn engine switch to OFF.

• Inspect continuity between ECT sensor

terminal A and body GND.

• Is there continuity?

Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

Loading...

Loading...