OIL PAN

D–11

D

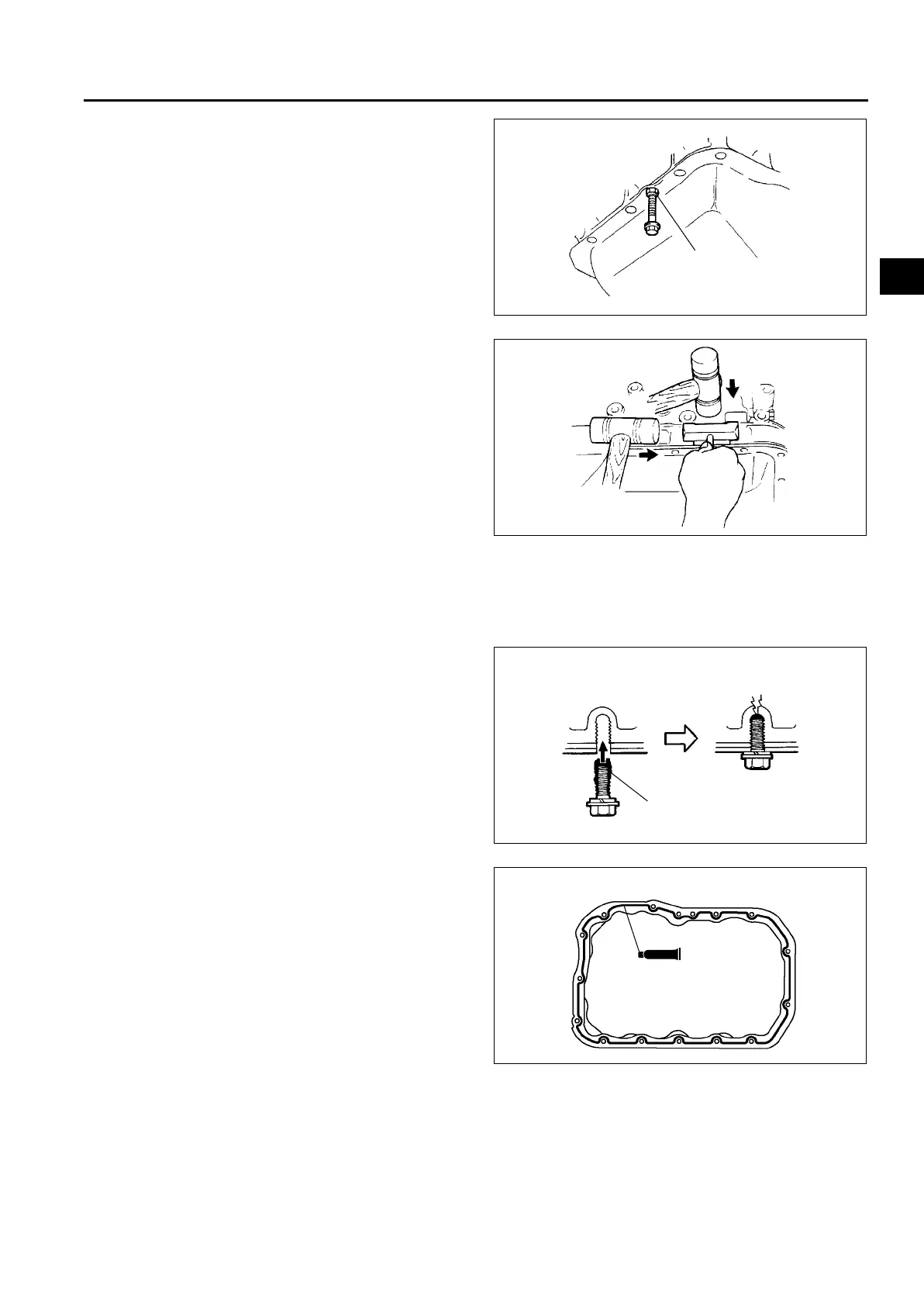

3. Screw an oil pan bolt into the weldnut to make a

small gap between the cylinder block and the oil

pan.

4. Remove the oil pan using the separator tool.

Oil Pan Installation Note

Caution

• If the bolts are reused, remove the old sealant from the bolt threads. Tightening a bolt that has old

sealant on it can cause bolt hole damage.

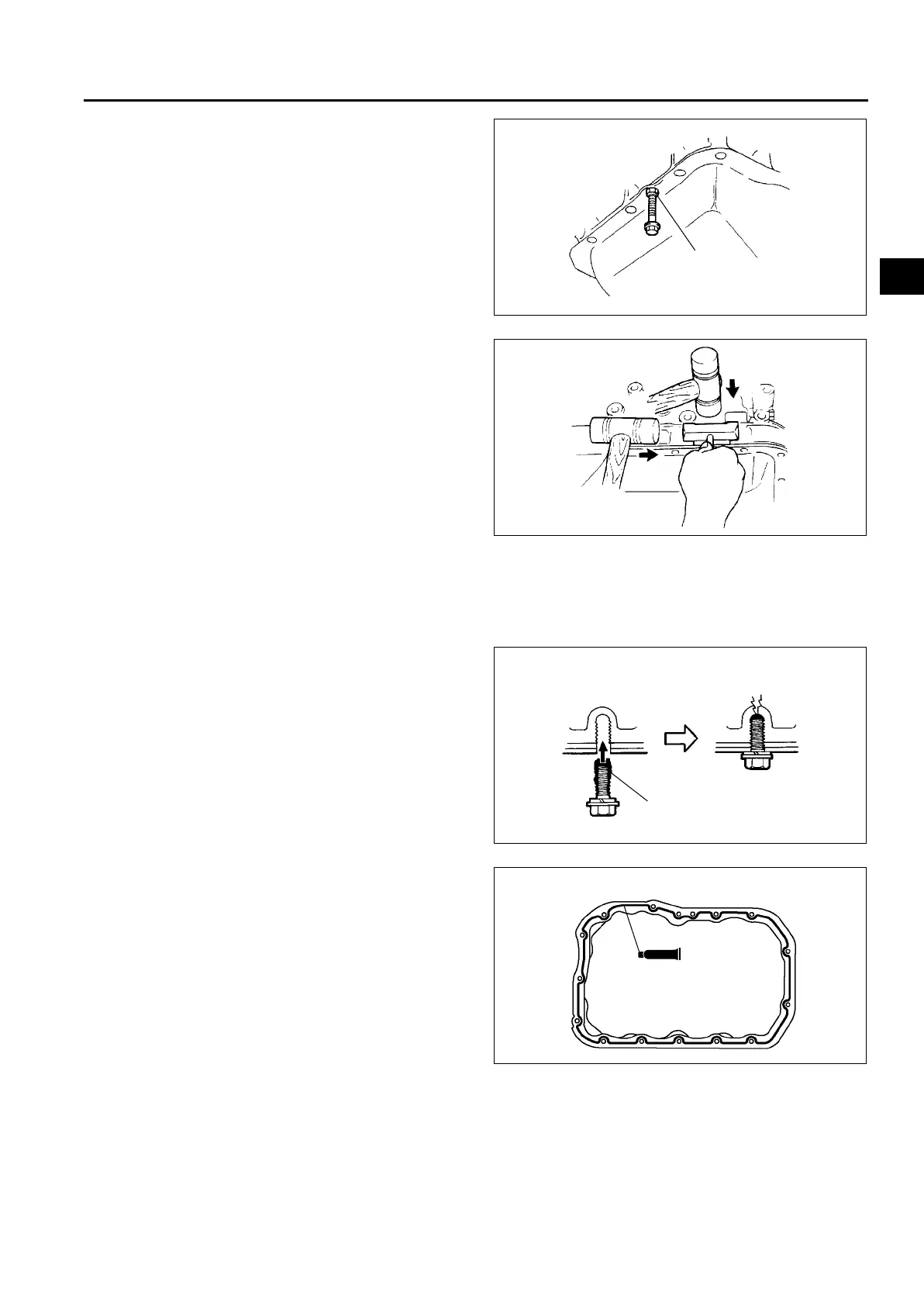

1. Apply silicone sealant to the oil pan along the

inside of the bolt holes and overlap the ends.

Thickness

2.5—3.5 mm {0.099—0.137 in}

2. Install the oil pan.

3. Hand tighten the flangeless bolts and tighten the

flanged bolts

Tightening torque

7.9—10.7 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf}

End Of Sie

WELD NUT

A6E3320W101

A6E3320W102

OLD SEALANT

CRACKS

A6E3320W103

SEALANT

A6E3320W104

Loading...

Loading...