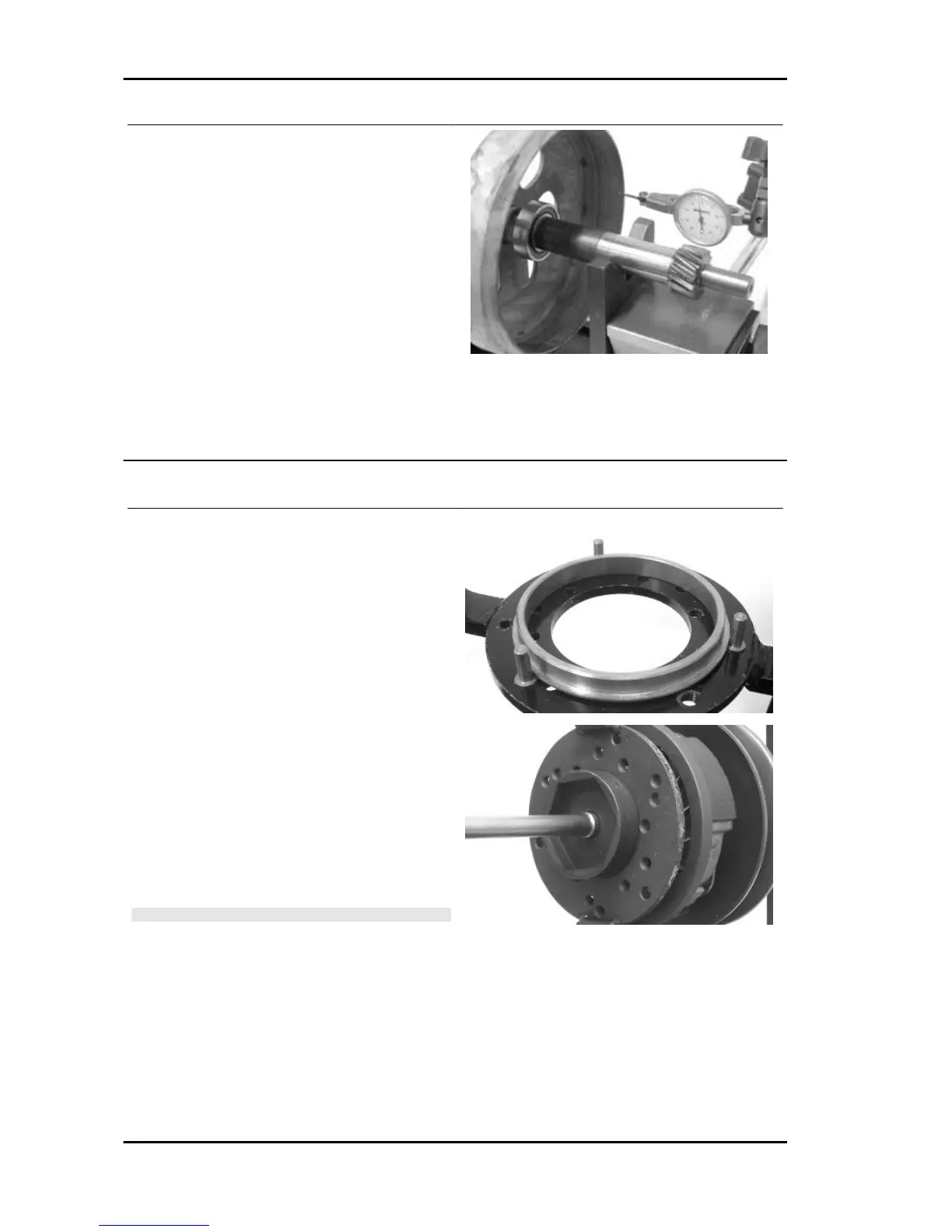

- Using a feeler dial gauge and the magnetic base,

measure the bell eccentricity.

- Repeat the measurement in 3 positions (Central,

internal, external).

- If faults are found, replace the bell.

Specific tooling

020074Y Support base for checking crankshaft

alignment

020335Y Magnetic support for dial gauge

Characteristic

clutch housing inspection: Limit eccentricity.

Admissible limit eccentricity: 0.15 mm

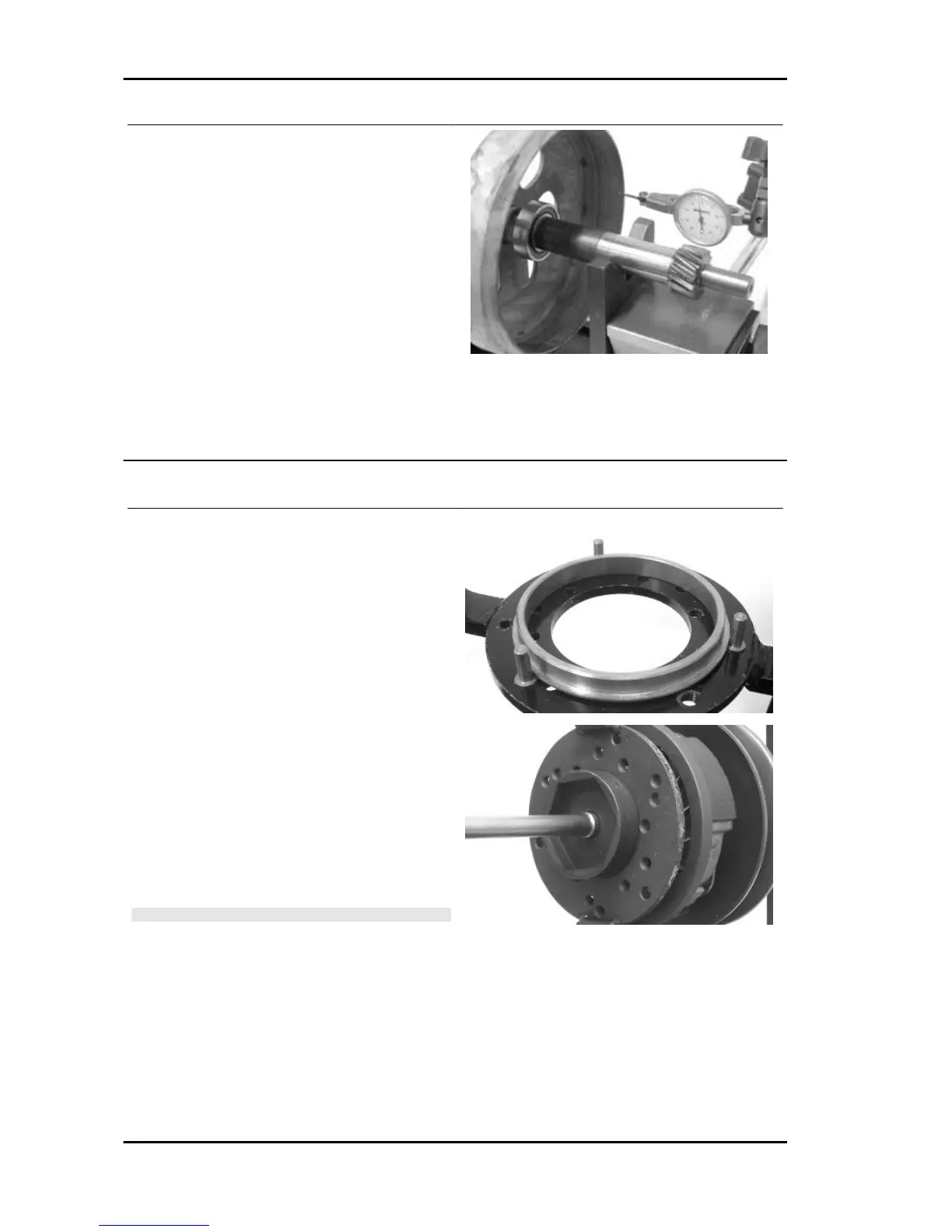

Removing the clutch

Fit the driven pulley spring compressor specific

tool with medium length pins screwed in position

«C» on the tool internal side.

- Introduce the adapter ring 11 with the chamfering

facing the inside of the tool.

- Fit the driven pulley unit on the tool with the in-

sertion of the 3 pins in the ventilation holes in the

mass holder support.

- Make sure that the clutch is perfectly inserted into

the adapter ring before proceeding to loosen/tight-

en the clutch nut.

- Use the special 46x55 wrench component 9 to

remove the nut fixing the clutch in place.

- Dismantle the driven pulley components (Clutch

and spring with its plastic holder)

CAUTION

THE TOOL MUST BE FIRMLY FIXED IN THE CLAMP AND

THE CENTRAL SCREW MUST BE BROUGHT INTO CON-

TACT WITH THE TOOL. EXCESSIVE TORQUE CAN CAUSE

THE SPECIFIC TOOL TO BUCKLE.

Specific tooling

020444Y011 adapter ring

020444Y009 wrench 46 x 55

020444Y Tool for fitting/ removing the driven

pulley clutch

Engine Beverly 300 i.e.

ENG - 112

Loading...

Loading...