Removing the driven half-pulley bearing

- Check there are no signs of wear and/or noisi-

ness; - Replace with a new one if there are.

- Remove the retainer ring using two flat blade

screwdrivers.

- Support the pulley bushing adequately from the

threaded side using a wooden surface.

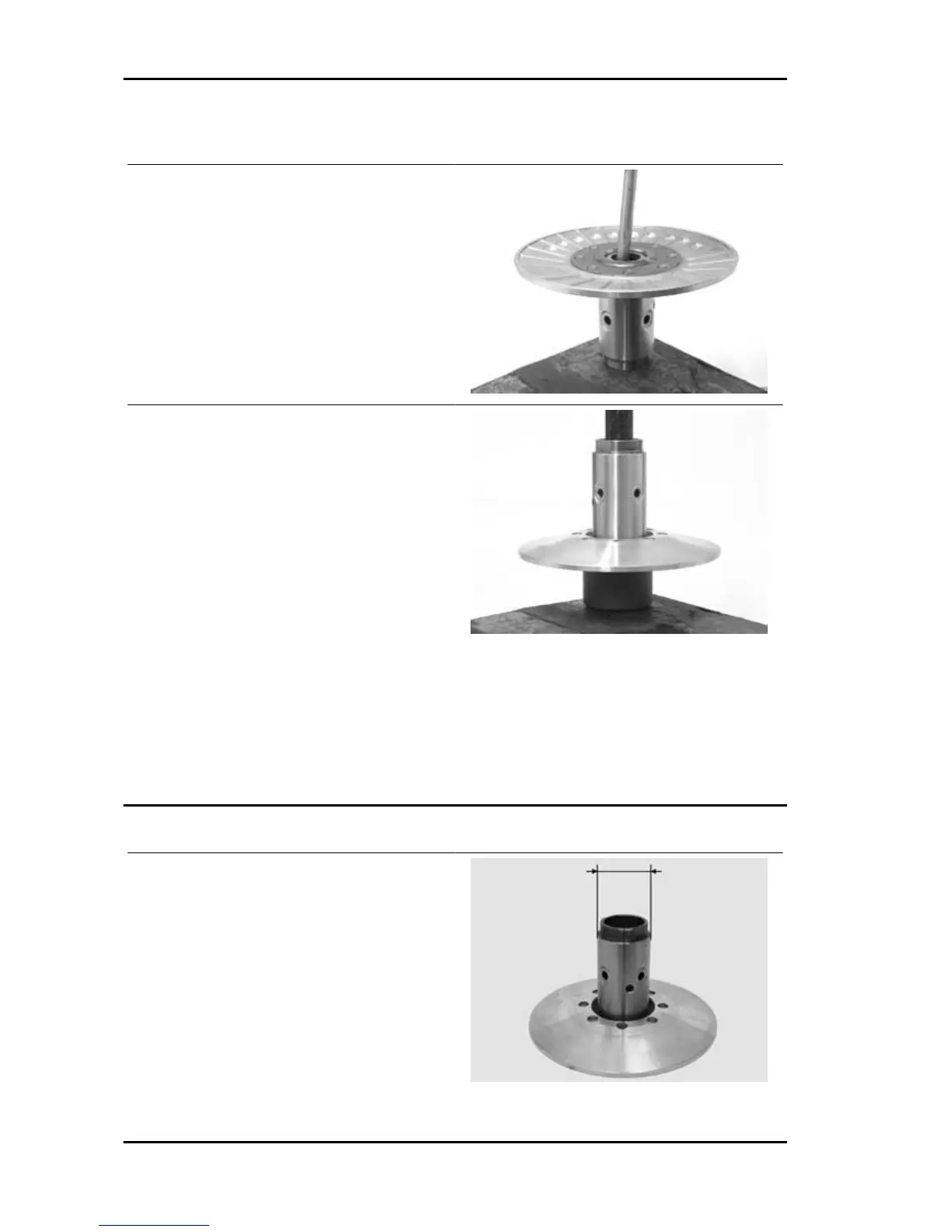

- Using a hammer and pin, knock the ball bearing

out as shown in the figure.

- Support the pulley properly using the bell as

shown in the figure.

Specific tooling

001467Y035 Bearing housing, outside ø 47 mm

- Remove the roller bearing using the modular punch.

Specific tooling

020376Y Adaptor handle

020456Y Ø 24-mm adaptor

020363Y 20-mm guide

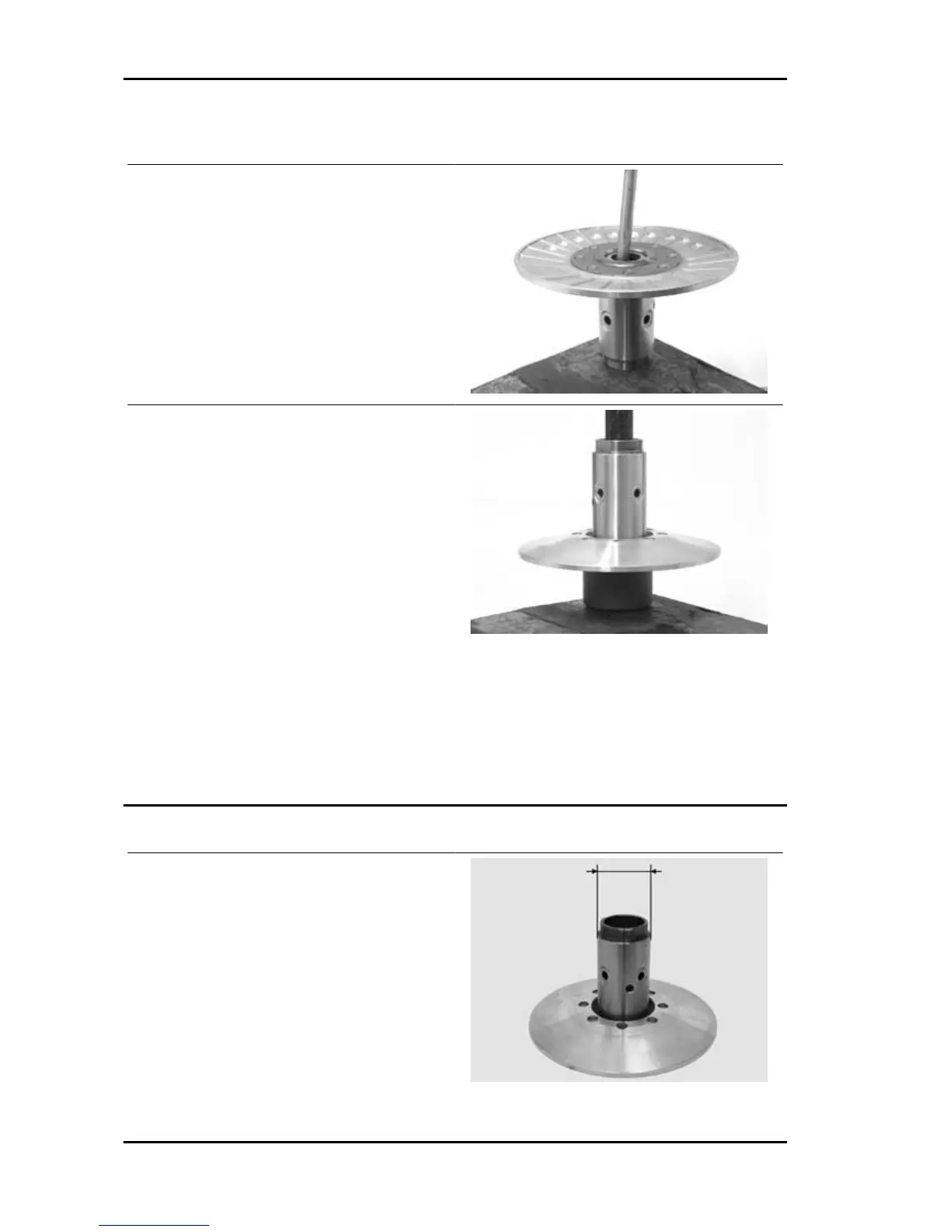

Inspecting the driven fixed half-pulley

Version 250

- Measure the outside diameter of the pulley bush-

ing.

- Check the faying surface with the belt to make

sure there are no flaws.

- Check the riveted joints are functional.

- Check the evenness of the belt contact surface.

Characteristic

Half-pulley minimum diameter

Minimum admissible diameter: Ø 40.96 mm

Engine Beverly 300 i.e.

ENG - 114

Loading...

Loading...