Refitting the rocker-arms cover

- Refit the cylinder head cover and tighten the 5

clamping screws to the prescribed torque.

- Make sure the gasket is positioned properly.

Locking torques (N*m)

Tappet cover screws 5 - 6 Nm

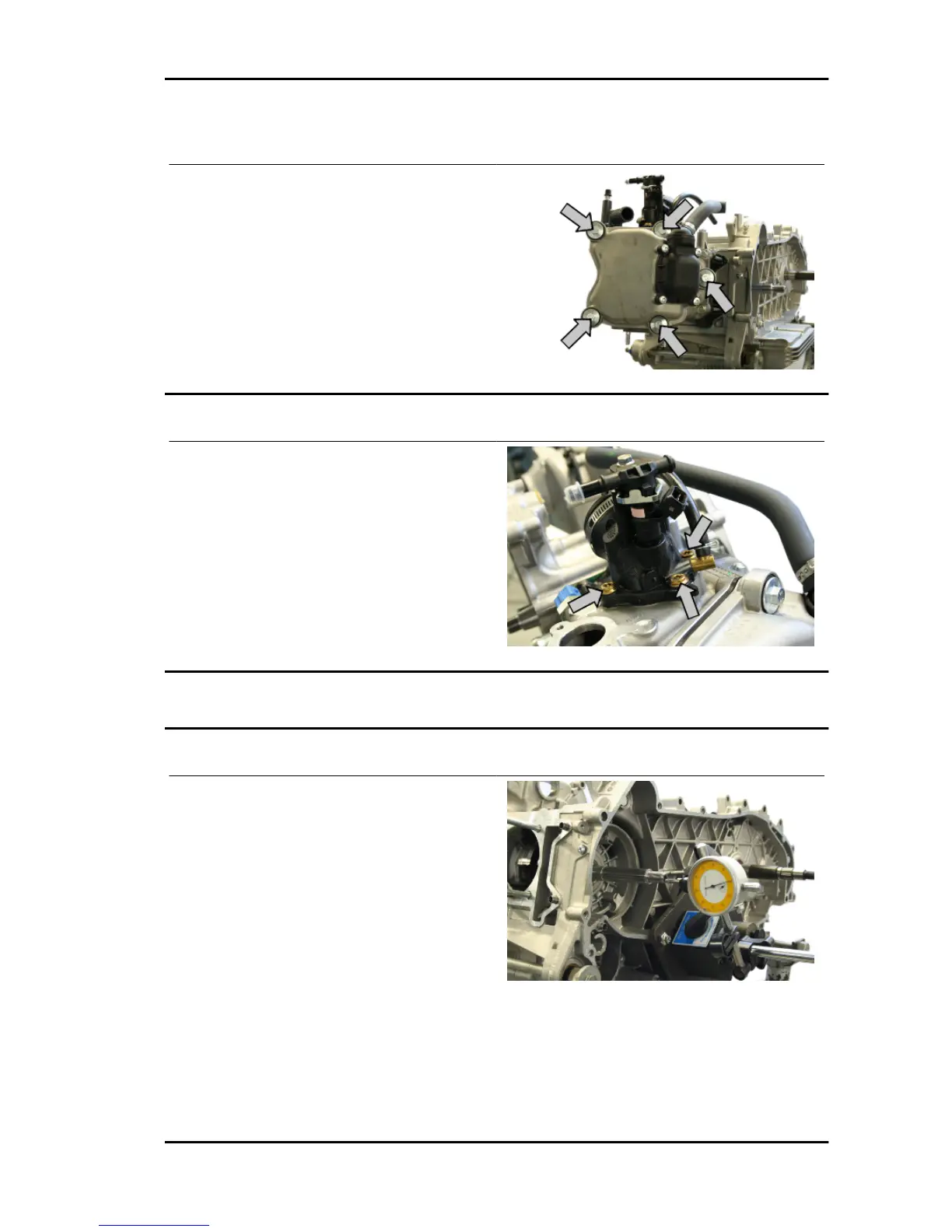

Refitting the intake manifold

- Fit the intake manifold and do up the three

screws.

Locking torques (N*m)

Intake manifold screws 11 ÷ 13

Crankcase - crankshaft

Splitting the crankcase halves

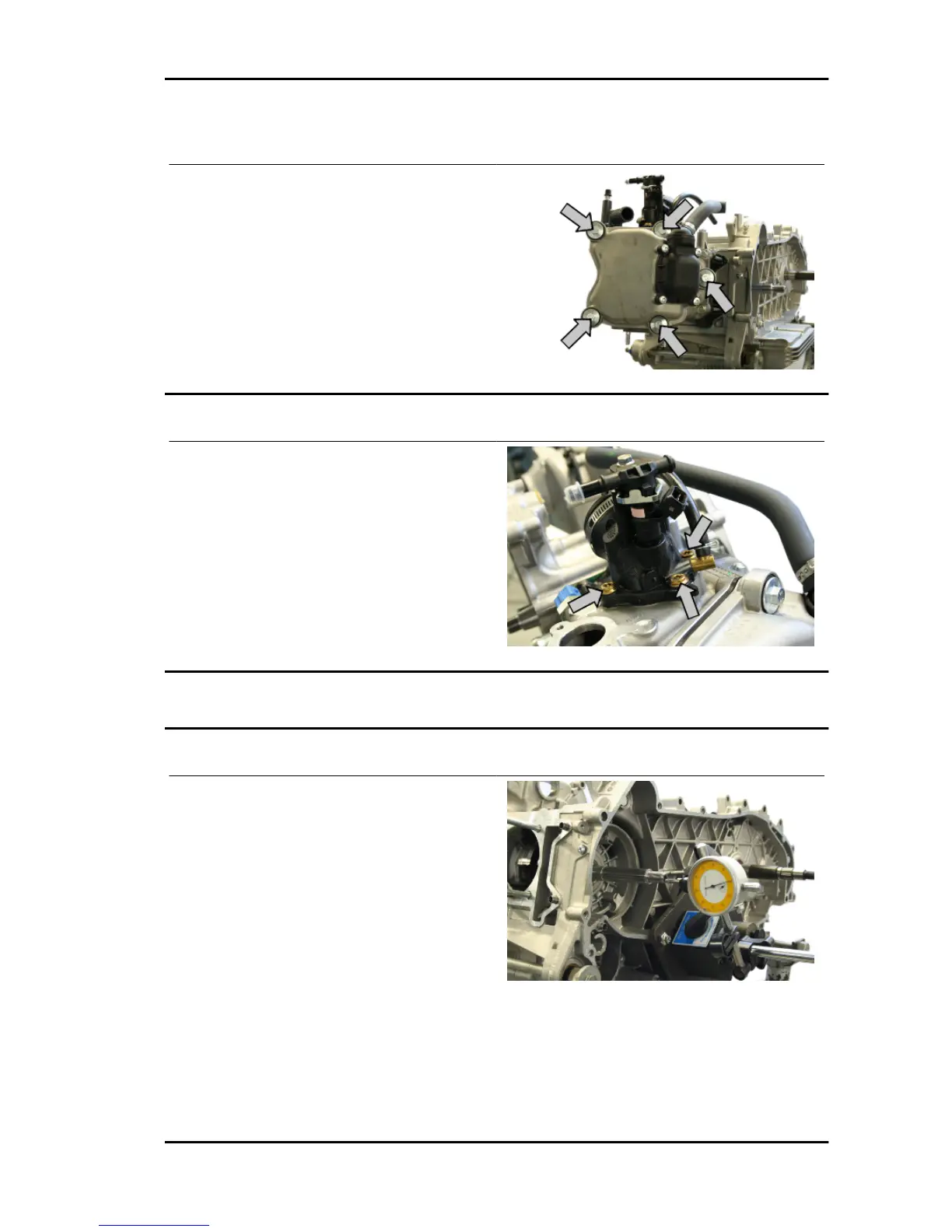

AXIAL CLEARANCE CHECK

- Before opening the engine crankcase, it is ad-

visable to check the axial clearance of the crank-

shaft. Use a specific tool to check axial clearance.

- Higher clearances are signs of wear on the crank-

shaft - crankcase supporting surfaces.

Specific tooling

020262Y Crankcase splitting plate

020335Y Magnetic support for dial gauge

Characteristic

Axial crankshaft/crankcase clearance: Stand-

ard clearance

0.15 - 0.40 mm (when cold)

Beverly 300 i.e. Engine

ENG - 151

Loading...

Loading...