THE TORQUE SERVER CAN BE GREASED WHETHER

WITH BEARINGS FITTED OR WHEN THEY ARE BEING RE-

PLACED; UNDERTAKING THE OPERATION WHEN THE

BEARINGS ARE BEING SERVICED MIGHT BE EASIER.

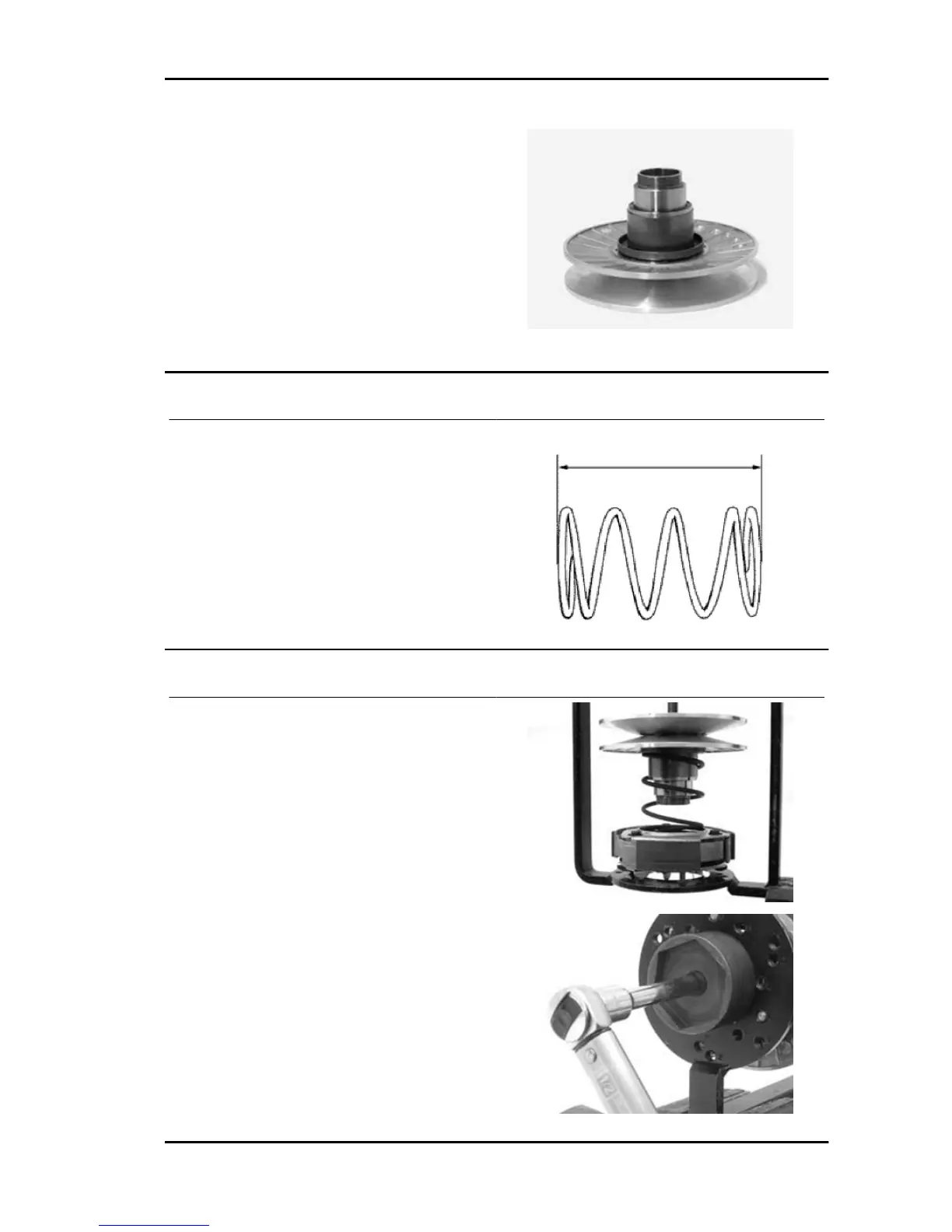

Specific tooling

020263Y Driven pulley assembly sheath

Recommended products

AGIP GREASE SM 2 Gray black smooth-tex-

tured lithium grease, containing molybdenum

disulphide.

-

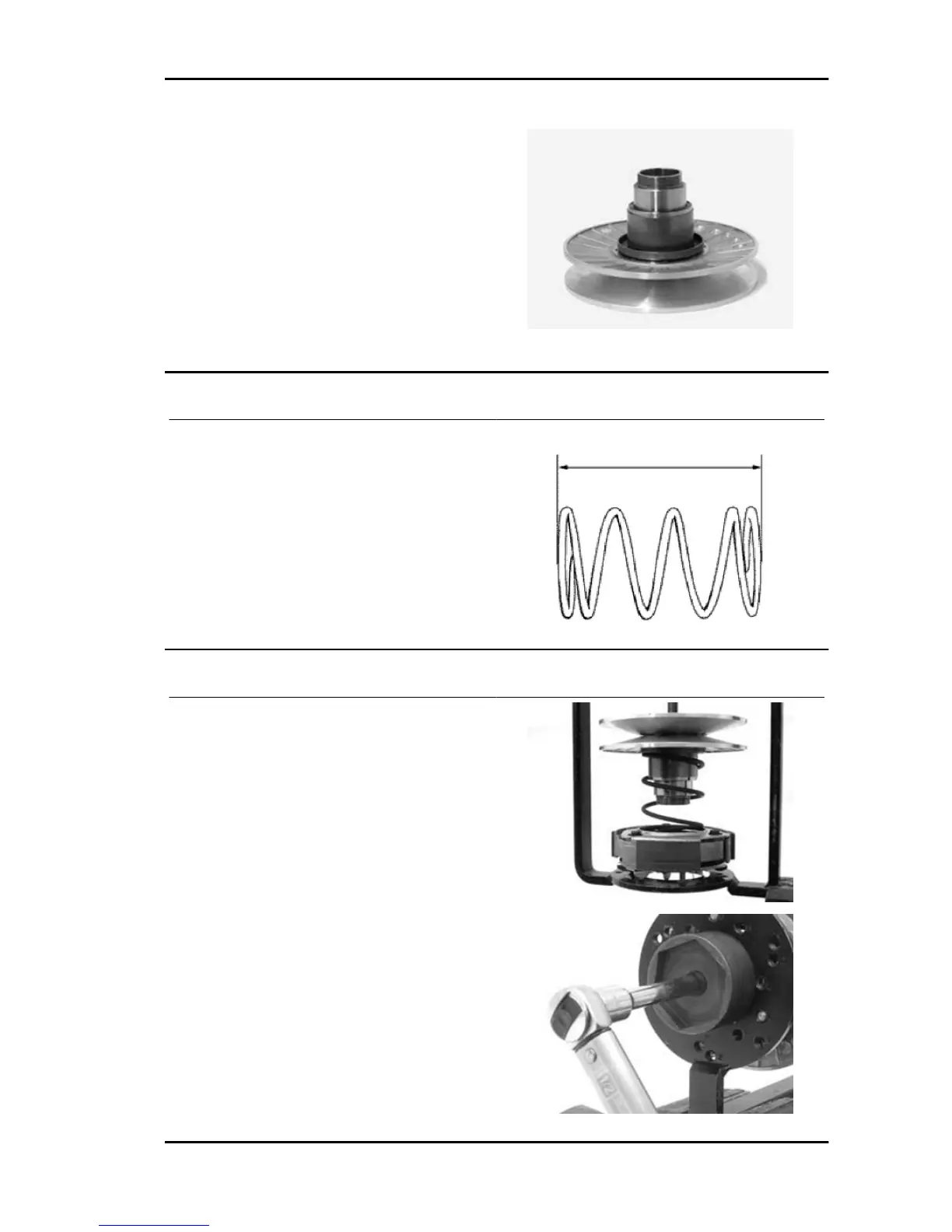

Inspecting the clutch spring

- Measure the length of the spring when it is re-

laxed.

Characteristic

Standard length

145 mm

Acceptable limit after use

140 mm

Refitting the clutch

- Support the driven pulley spring compressor spe-

cific tool with the control screw in vertical axis.

- Arrange the tool with the medium length pins

screwed in position "C" on the inside.

- Introduce the adapter ring No. 11 with the cham-

fering facing upwards.

- Insert the clutch on the adapter ring.

- Lubricate the end of the spring that abuts against

the torque server closing collar.

- Insert the spring with its plastic holder in contact

with the clutch.

- Insert the drive belt into the pulley unit according

to their direction of rotation.

- Insert the pulley unit with the belt into the tool.

- Slightly preload the spring.

Beverly 300 i.e. Engine

ENG - 117

Loading...

Loading...