SERVICE PROGRAM MODE 26 July 2002

5-18

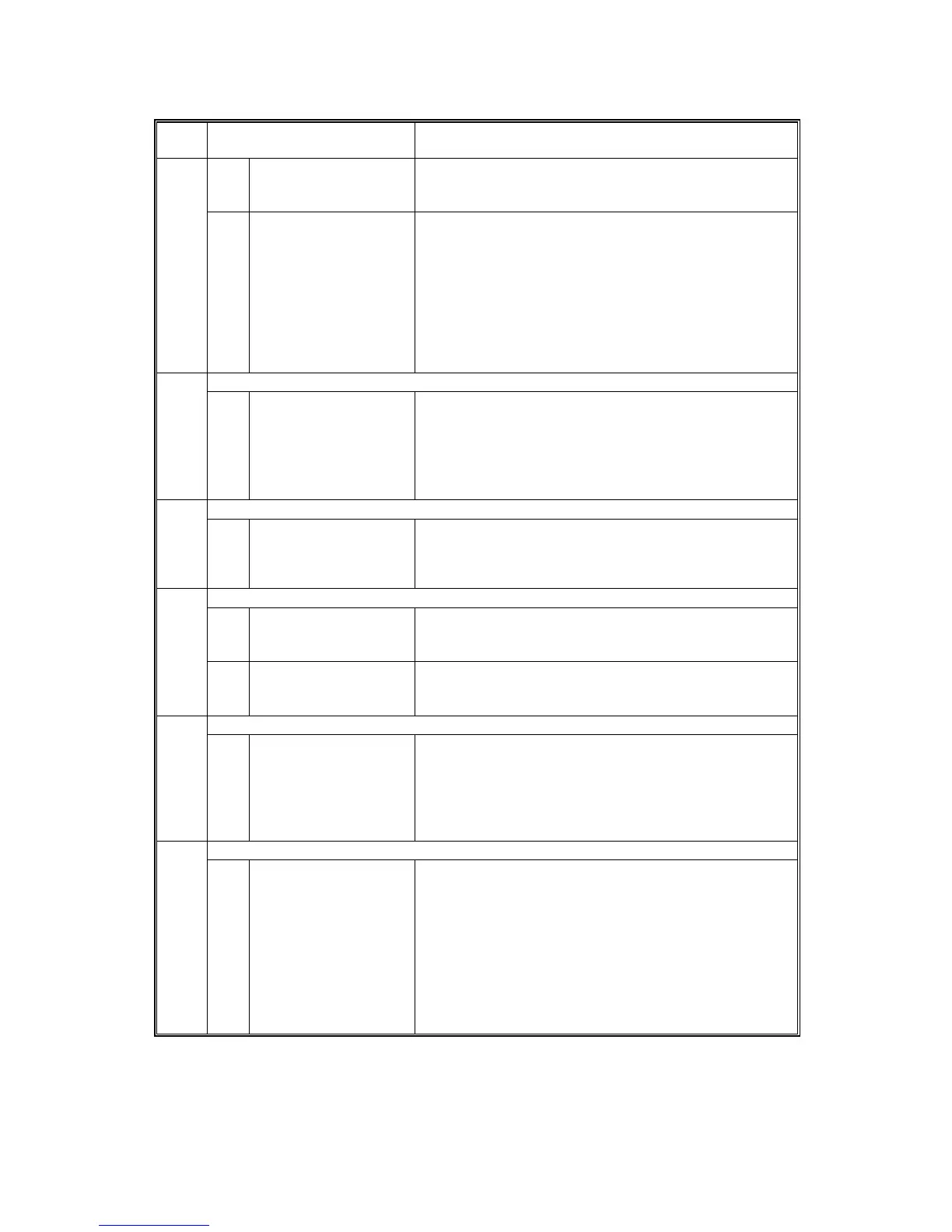

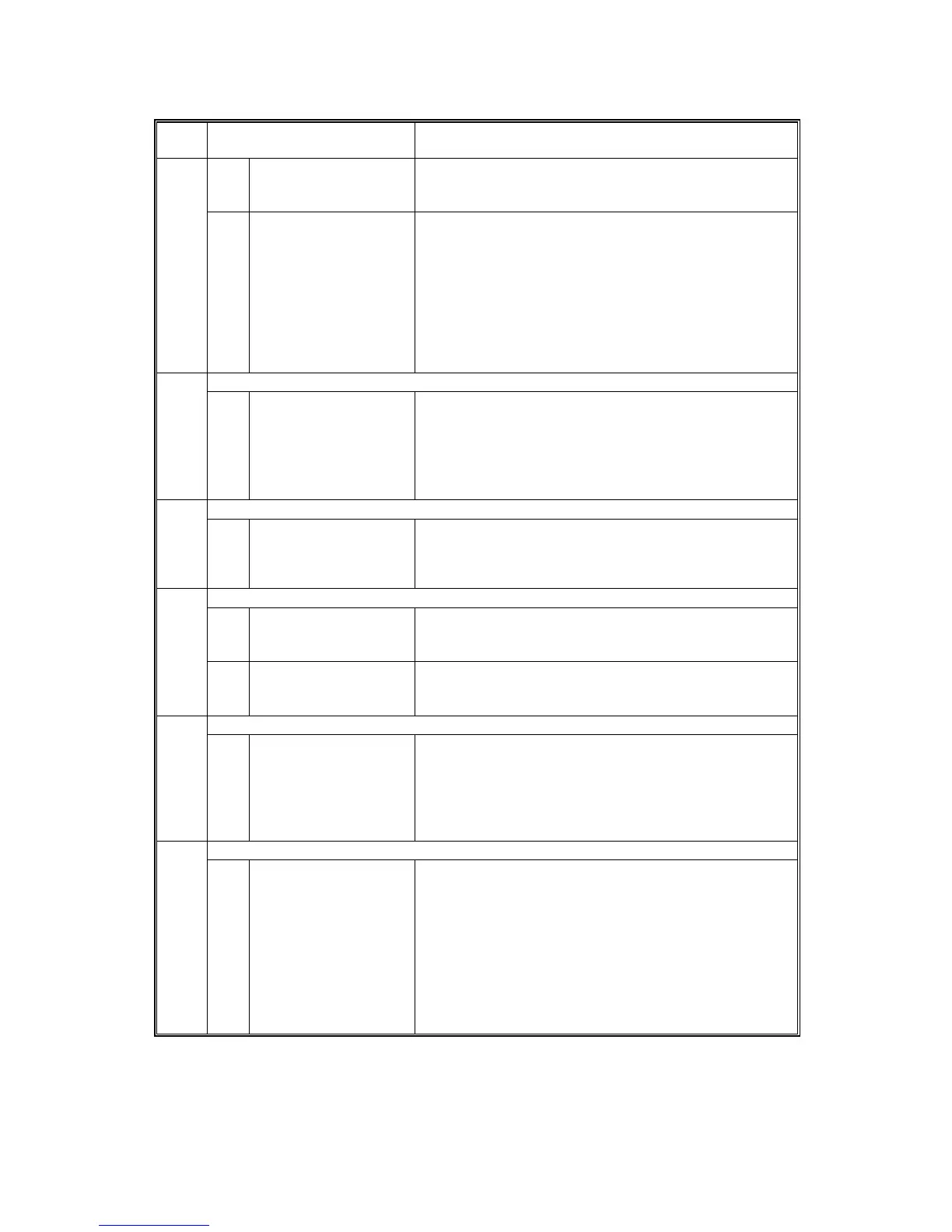

2

Mode No.

(Class 1, 2, and 3)

Function / [ Setting ]

3 Humidity 2

Displays the absolute humidity calculated from the

temperature/humidity sensor readings.

[0 ~ 65535 / 0 / 0.1 g/m

3

/step]

912*

4 Environment Level

Displays the current humidity level calculated from the

absolute humidity.

[0 ~ 1 / 0 / 1/step]

• LL1: 0 < AH

≤

3.5

• LL2: 3.5 < AH

≤

8.0

• NN1: 8.0 < AH

≤

14

• NN2: 14 < AH

≤

19

• HH: 19 < AH

* AH = absolute humidity

OPC lubricant interruption (Forced OPC lubrication) 939

1

Enables/disables forced OPC lubrication at a certain

interval. DFU

[0 ~ 1 / 0 / 1 /step]

• 0: Disabled

• 1: Enabled

The OPC lubrication interval is specified with SP2-942-1.

OPC Lubricant Mode 940

1 OPC Lubricant Mode

Executes a forced OPC lubrication to reduce the friction

on the OPC belt. DFU

The OPC belt and the lubricant brush operate for 2

minutes.

OPC Lubricant Time

1 Interrupt

Determines how long the OPC belt is lubricated for after

the end of every job (☛ SP3–940).

[0 ~ 30 / 20 / 1 s/step]

941

2 No Interrupt

Determines how long the OPC belt is lubricated at the

forced lubrication.

[0 ~ 60 / 10 / 1 s/step]

OPC Lubricant Interval 942

1 OPC Lubricant Interval

The machine lubricates the OPC belt and image transfer

belt at the interval (number of prints) set with this SP.

Incoming print jobs do not interrupt the lubrication.

[10 ~ 65535 / 50 / 10/step] DFU

Set SP2-939-1 to 1 to execute the forced OPC

lubrication.

OPC Lubrication: High Coverage 944

1 Setting

Enables/disables OPC lubrication after a certain amount

of images are printed. The lubrication timing depends on

SP2-944-2 to -5.

[0 ~ 1 / 1 / 1 /step]

• 0: Disables

• 1: Enables

When high coverage images are continuously printed,

cleaning of the OPC may not be enough. To correct this,

OPC lubrication is carried out during printing (lubrication

time: around 34 seconds).

Loading...

Loading...