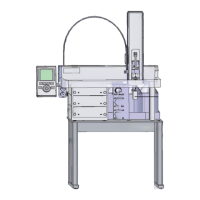

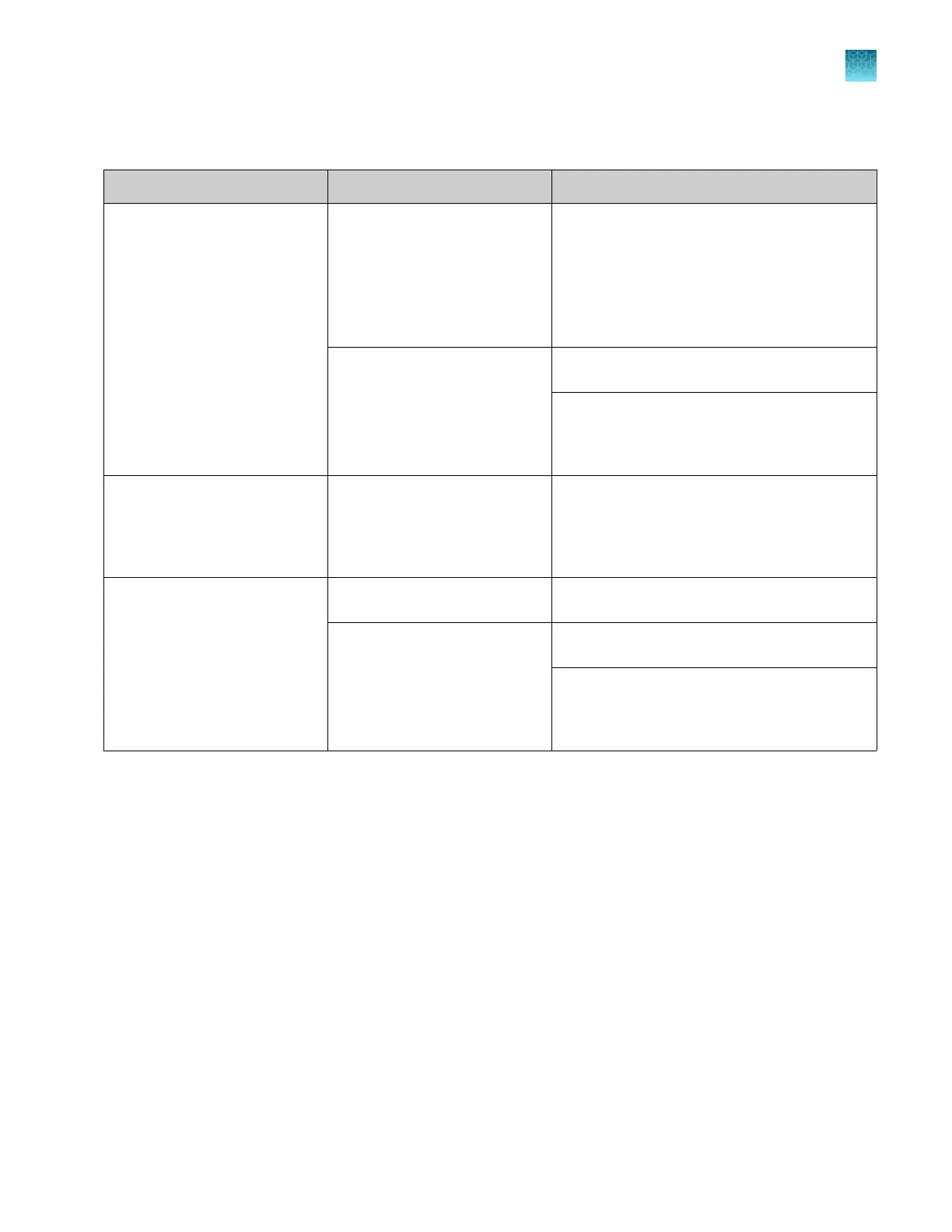

Troubleshoot calibration failure

Observation Possible cause Recommended action

Calibration failed

The plate was improperly

prepared.

Ensure the following:

•

The correct plate was used for the

calibration performed.

•

The plate was properly thawed.

•

The plate was properly centrifuged.

•

The plate was properly sealed.

The plate is damaged or

contaminated.

Check for damage, improper plate seal, or

contamination.

Order a replacement plate. Use Smart Help

if the replacement plate fails (see “Request

technical support with Smart Help” on

page 172).

High fluorescence signal in

individual wells

Signals that exceed the

limit of normal fluorescence

may indicate fluorescent

contaminants on the plate or the

sample block.

See “Identify contamination” on page 95.

Calibration failed but plate is

undamaged

The incorrect plate was used for

calibration performed.

Use the plate that matches the calibration

performed.

The plate was improperly

prepared.

Repeat the calibration with the plate properly

prepared.

If the calibration fails again, order a replacement

plate. Use Smart Help if the replacement plate

fails (see “Request technical support with Smart

Help” on page 172).

Identify contamination

Signals that exceed the limit of normal fluorescence may indicate fluorescent contaminants on the

calibration plate or the sample block. Common contaminants include ink residue from permanent pens,

powder from disposable gloves, and dust.

1.

View the calibration data and note the wells that failed the calibration.

2.

Remove the plate from the instrument, rotate the plate 180°, then perform the calibration again.

Chapter 7 Calibrate and verify instrument performance

Perform ROI/uniformity, background, and dye calibrations for plate blocks

7

QuantStudio

™

6 Pro Real-Time PCR System and QuantStudio

™

7 Pro Real-Time PCR System User Guide

95

Loading...

Loading...