Commonly Used Procedures 6

Agilent Nano Indenter G200 User’s Guide 6-31

Frame Stiffness and Area Function Calibration

The first step in calibrating the frame stiffness and area function is to

acquire data on fused silica over a range of displacements.

There are three methods from which the user may determine machine

compliance. These methods are:

• Frame Stiffness and Area Function Calibration: Express Test using

rapid indentation.

• Frame Stiffness Calibration: ISO 14577 Method using quasi-static

indentation.

• Frame Stiffness Calibration: CSM Method using dynamic

indentation.

See Frame Stiffness and Indenter Area Function Theory in Chapter 7,

"Theory" for more theoretical information.

General Information

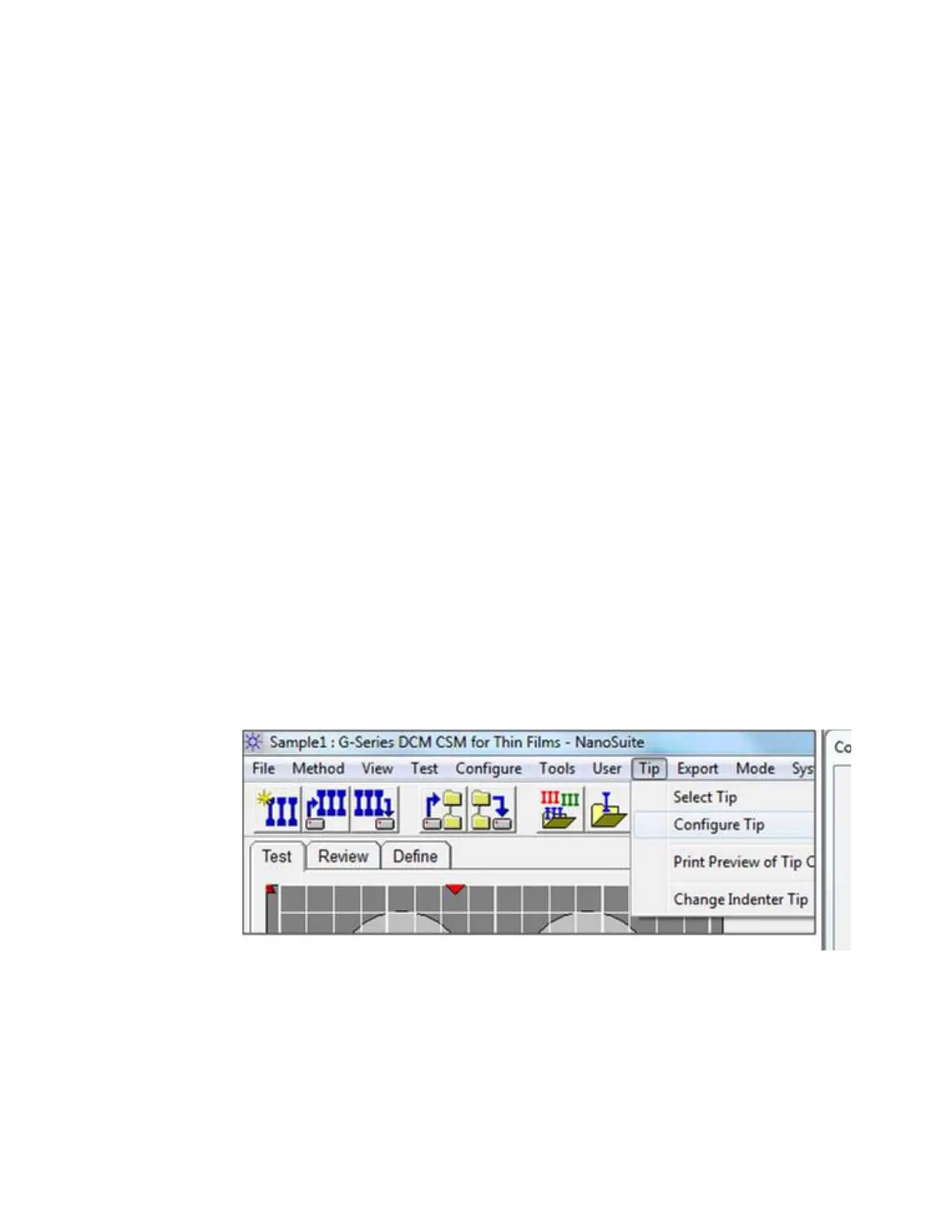

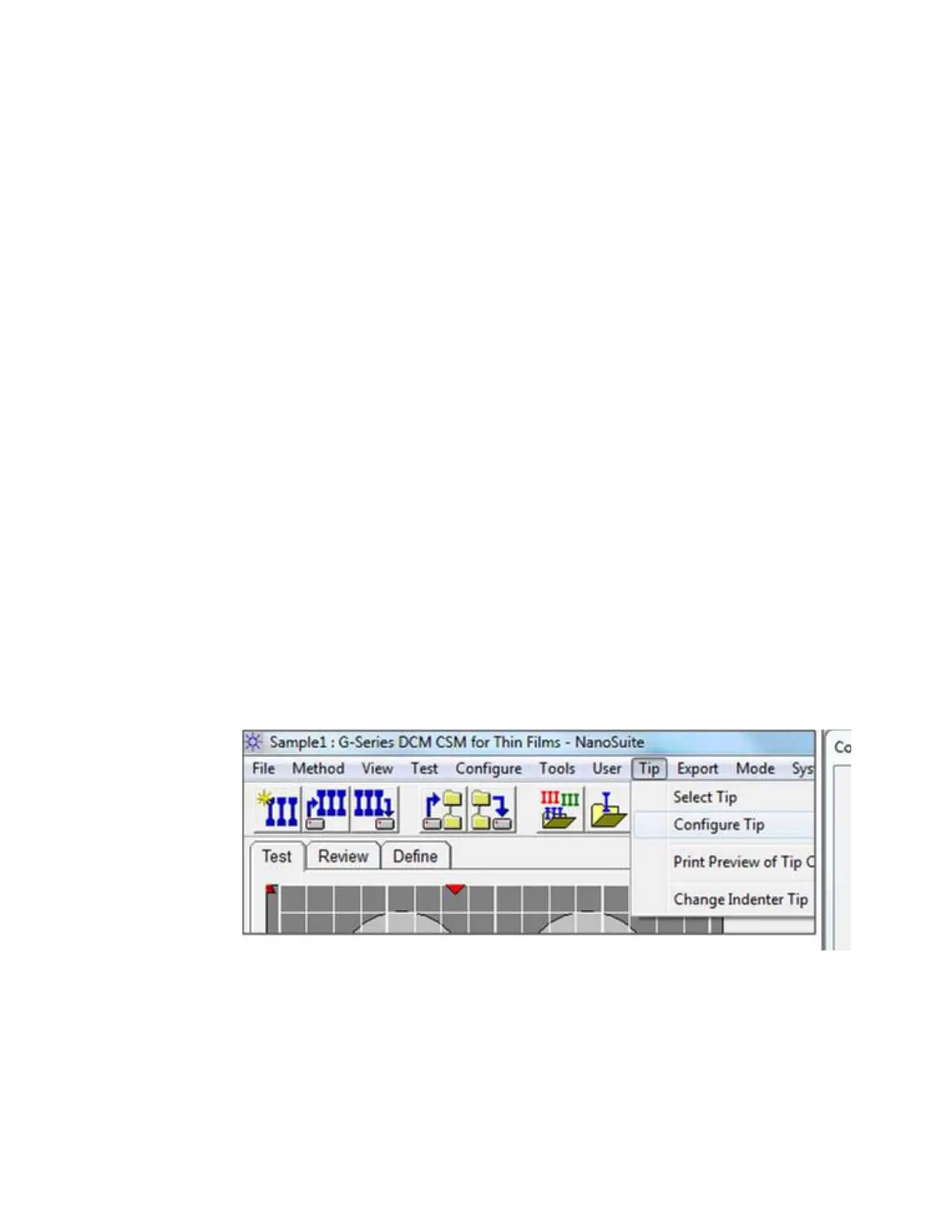

Frame stiffness and area function information are stored in the same

location. To access the information, choose Tip > Configure Tip from

the main menu as shown in

Figure 6-45.

Figure 6-45Select Configure Tip from the Tip menu

Tip definitions are stored by user-defined names. The recommended

convention to use is Serial No.

Date Method (ie TB12938 042812

Express Test) as shown in

Figure 6-46 on page 6-32.

Loading...

Loading...