Theory 7

Agilent Nano Indenter G200 User’s Guide 7-3

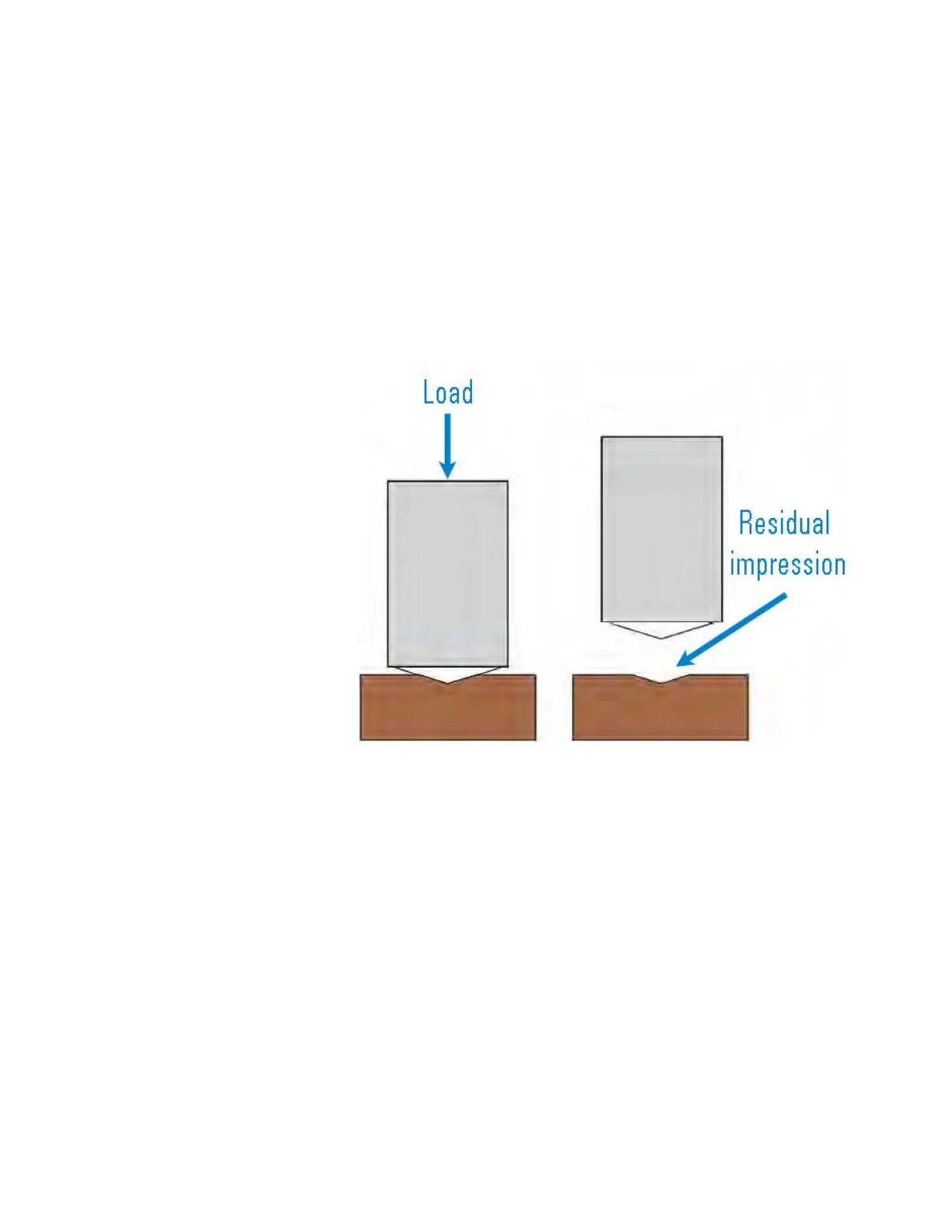

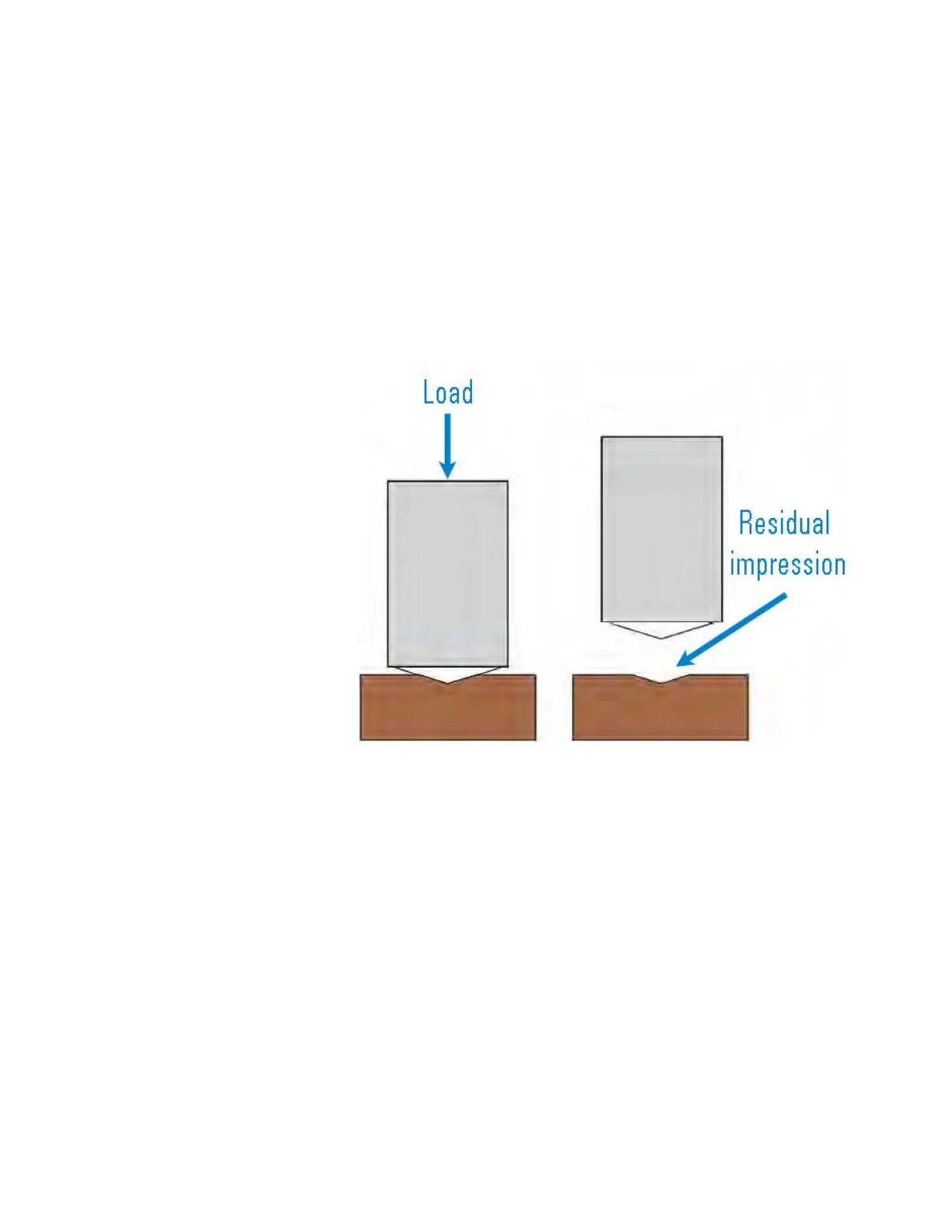

Indentation Process Overview

As the indenter is driven into the material, both elastic and plastic

deformation cause the formation of a hardness impression conforming

to the shape of the indenter to some contact depth, h

c

, as shown in

Figure 7-1. As the indenter is withdrawn, only the elastic portion of the

displacement is recovered; this recovery enables one to determine the

elastic properties of a material.

Figure 7-1Schematic of indentation load (left) and residual impression

(right)

Continuous Load-Displacement Data

A set of continuous load-displacement data is shown in Figure 7-2 on

page 7-4. Some important quantities are:

• Peak load (P

max

)

• Displacement (h

max

)

• Residual depth after unloading (h

f

)

• Slope (S) of the initial portion of the unloading curve, where

S= dP/dh (4)

Loading...

Loading...