1 689 989 300 2020-03-24| Robert Bosch GmbH

82 | EPS 118 | Maintenanceen

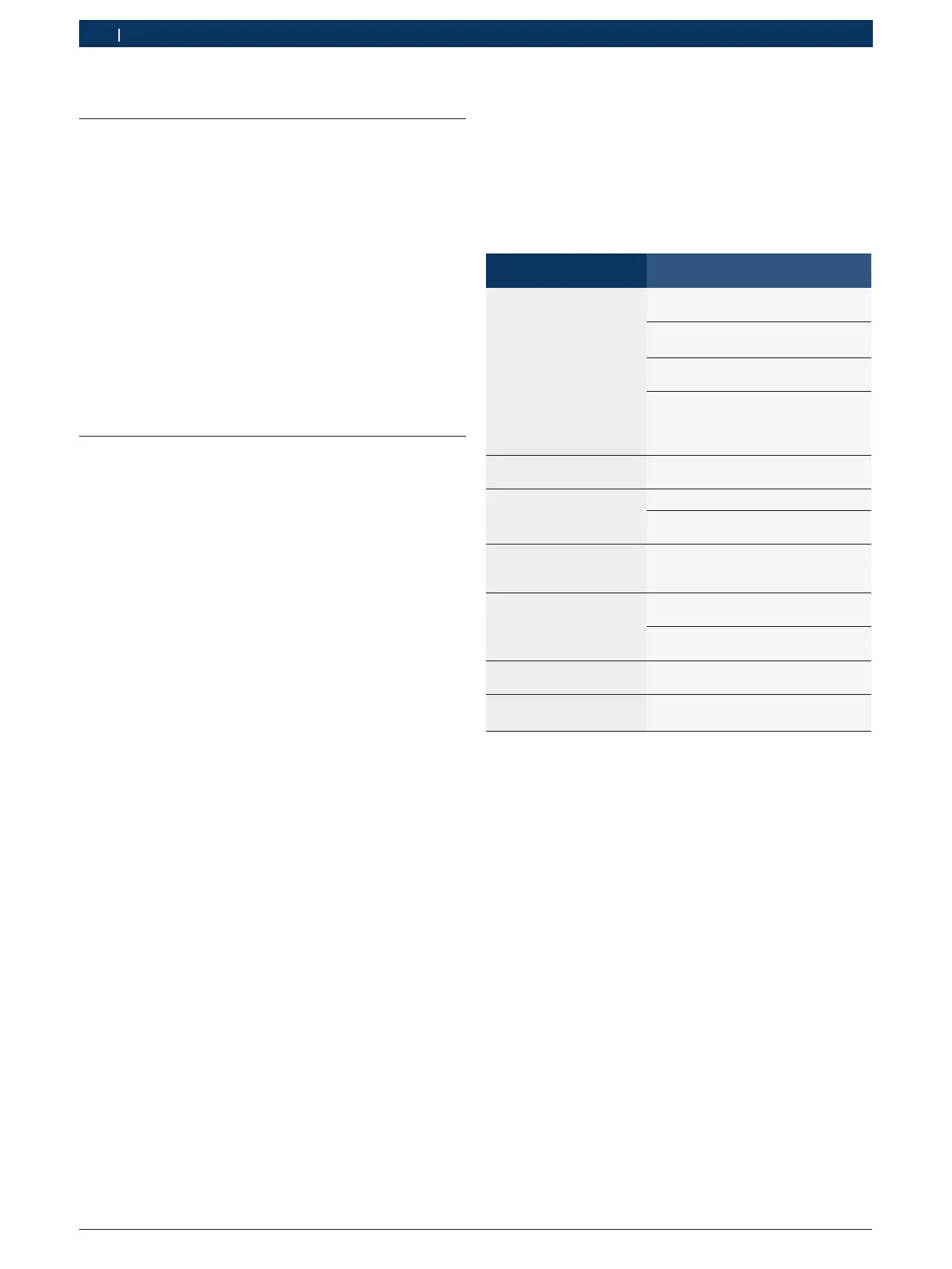

8.2.1 Service intervals

All of the maintenance intervals for the EPS 118are

listed below.

i All use-related maintenance intervals for the

EPS 118 are monitored anddisplayed on themain-

tenance screen (see section 6.7.8).

Service intervals Maintenance work

Daily

1)

Performing a leak test (see sec.

8.2.2)

Check hose assemblies

(see sec. 8.2.4)

Check the O-ring on the injection

nozzle seat (see sec.8.2.6)

Check the maintenance unit (Fig. 2,

item 2) for cracks and damage and

use the drain plug (Fig. 2, item 4) to

drain the condensate if necessary.

After 12 operating hours Change the strainer in all hose as-

semblies

(see sec.8.2.10)

Monthly

1)

Clean vent grilles (see sec. 8.1)

Clean injection chamber (see sec.

8.2.5)

After 100 operating

hours or 6 months at the

latest

Change the test oil (see sec. 8.2.7)

After 600 operating

hours

Change the test oil filter (see sec.

8.2.8)

Change the air filter in the water

separator (see sec. 8.2.11)

After 2400 operating

hours

2)

High-pressure pump maintenance

required. Inform customer service.

After 2 years at the la-

test

1)

Change the high-pressure hose as-

sembly (see sec. 8.2.3)

1)

Maintenance must be performed every 2 years during the main

inspection by the testing department/customer service.

2)

The operating hours meter can only be reset by customer ser-

vice.

8. Maintenance

8.1 Cleaning

Clean the protective hood with a damp cloth (water

and detergent only), or using a plastics cleaning agent.

! The protective hood may not be cleaned using alco-

hol-based cleaning agents such as glass cleaners.

Only use a soft cloth and neutral detergents to clean

the vent grille, housing and container of the mainte-

nance unit and the LCD touchscreen of the EPS 118.

Do not use abrasive cleaning agents and coarse work-

shop cloths.

! Always use clean/non-scratch cloths for cleaning

the LCD.

8.2 Service

As is the case with all technical devices, the EPS 118

requires expert servicing at regular intervals. The in-

dicated maintenance intervals (see section 8.2.1)as-

sume the daily8-hour operation of the EPS 118 with

a maximum 20 injector tests. if the operating time is

longer or if there are more injector tests, the mainte-

nance intervals should be shortened.

i Parts that are subject to wear from use or other na-

tural causes of wear or must be exchanged during

maintenance are not covered by the guarantee.

Loading...

Loading...