1 689 989 300 2020-03-24| Robert Bosch GmbH

84 | EPS 118 | Maintenanceen

1

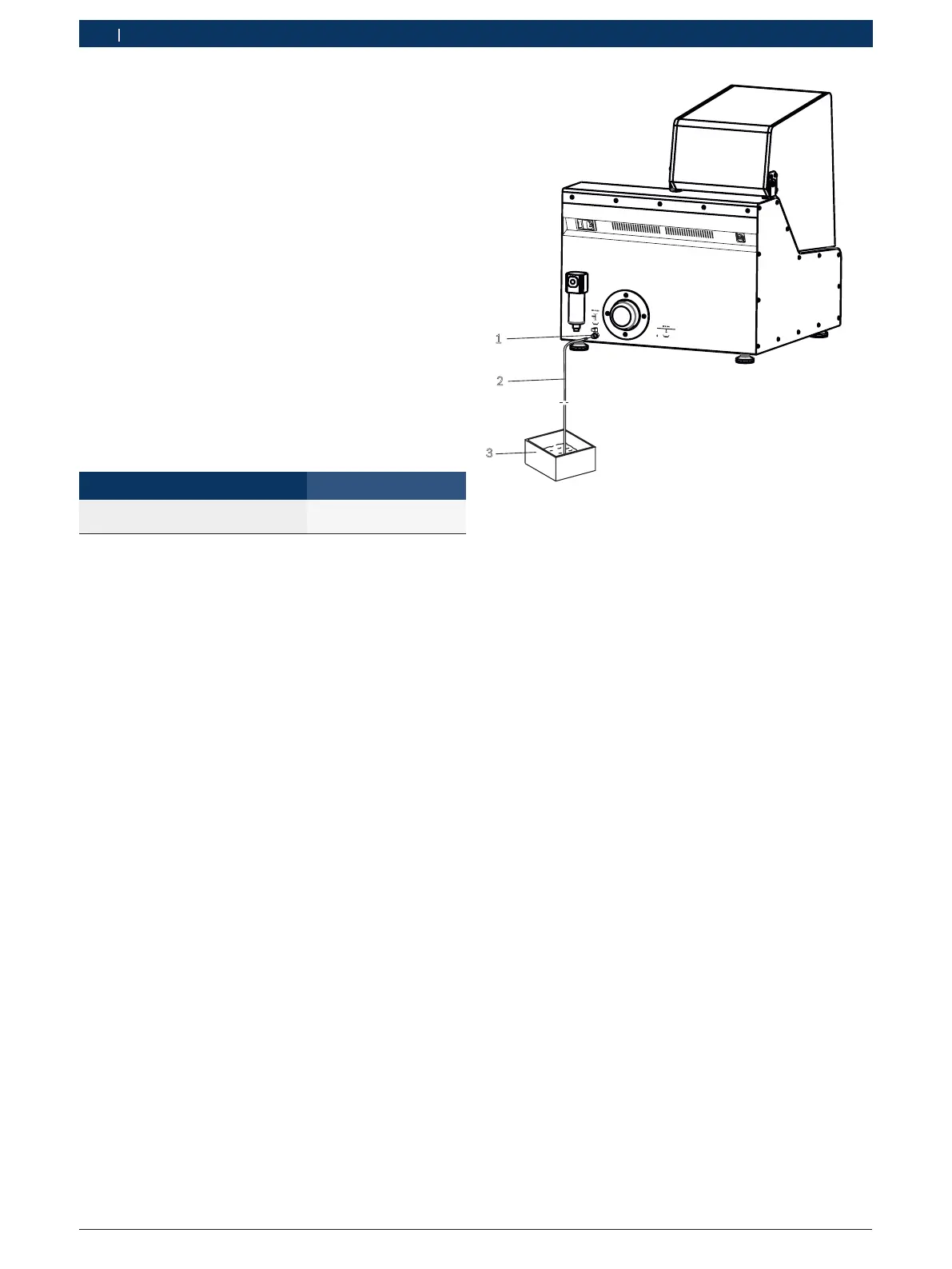

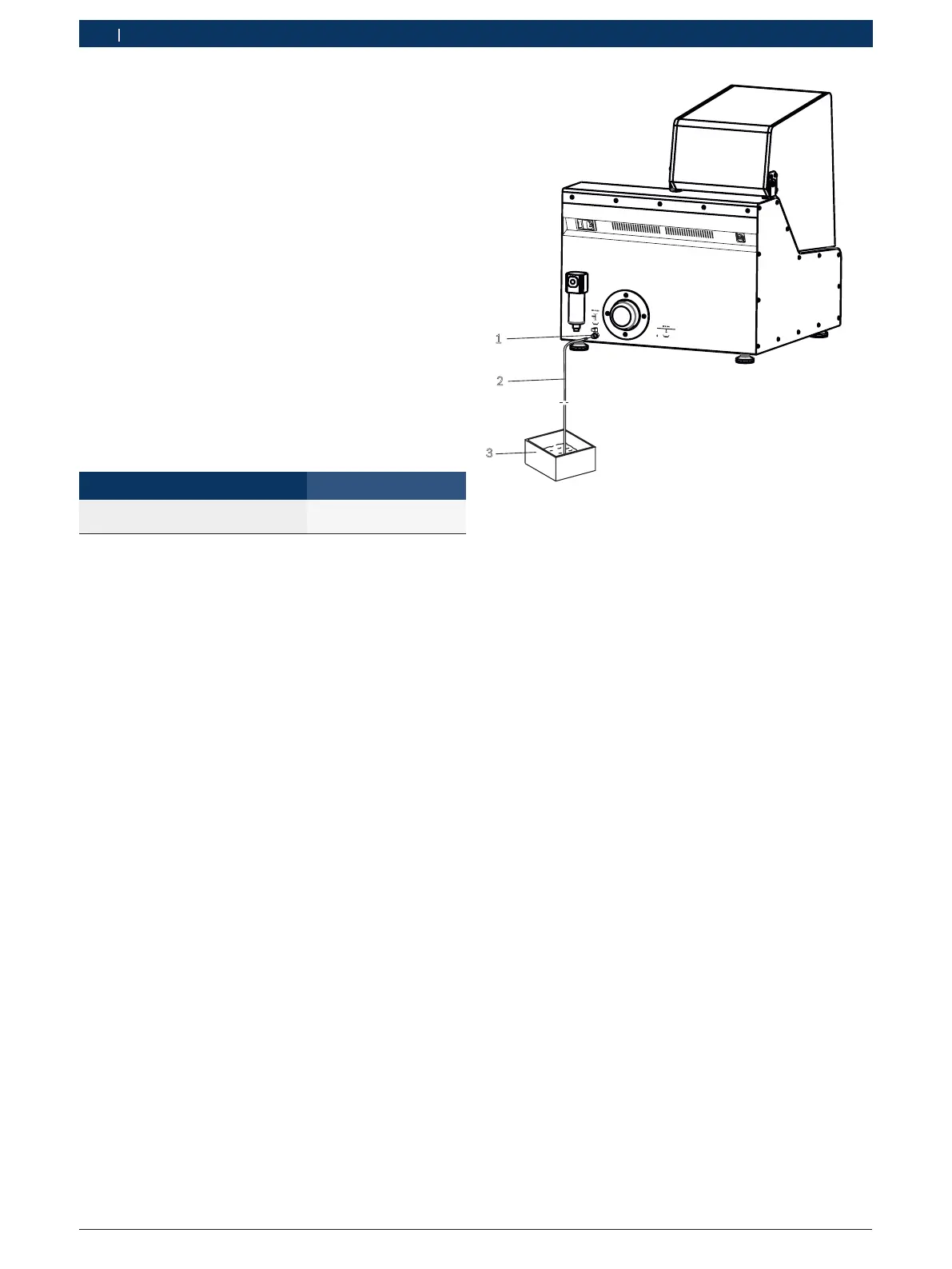

2

458900-07_Pal

Fig. 43: Draining test oil

1 Test oil drain shut-off valve

2 Hose assembly (not included in the scope of delivery)

3 Oil collector

6. Once the test oil has drained completely, turn off

the shut-off valve (Fig. 43, item1).

7. Remove the hose assembly.

8. Turn the knurled nuts counterclockwise and remove

them from the test oil filler port (Fig. 3, item9).

! If the test oil is poured in too quickly, it may run

out at the filler port. Immediately clean up test oil

spills with a cloth.

! Only fill the EPS 118 with test oil according to

ISO4113. Never use diesel fuel.

! The test oil level must be both above the mark of

the oil level indicator (Fig. 1, item. 4) and within

the sight glass. If the test oil level cannot be seen

in the within the sight glass, too much test oil has

been filled, which will distort the measured values.

9. Pour test oil (ISO4113) through the funnel very

slowly and carefully into the test oil filler port

(Fig. 3, item9). Pour in test oil until it is above

the mark on the oil level indicator (Fig. 1, item4)

(approximately 4,5l test oil).

10. Screw the knurled nut clockwise into the test oil

filler port (Fig. 3, item9).

11. Bleed the system (see sec. 8.2.10).

8.2.7 Changing test oil

! Before replacing the test oil, the EPS 118 must be

turned off and disconnected from the mains volta-

ge system.

! During use, the test oil is subject to the effects of

evaporation, temperature, pressure, oxidation and

the impact of foreign matter. Regular checking is

therefore essential to ensure compliance with the

necessary test oil quality standard when checking

injectors. Change the test oil at regular intervals

(see maintenance intervals). Always immediately

replace cloudy test oil even if the change interval

has not been reached. Contaminated test oil can

result in biased measured values and damage both

the EPS 118 and injectors during testing.

Permitted test oil types:

Test oil types Manufacturer

DIVINOL Calibration Fluid 2928V3 Zeller+Gmelin GmbH &

Co. KG

Procedure:

1. Switch off the EPS 118.

2. EPS 118 to be disconnected from the mains.

3. Connect the hose assembly (Fig. 43, item2, not

included in the scope of delivery) to the shut-off

valve (Fig. 43, item1). The shutoff valve has a 1/8"

thread for connecting a hose fitting.

4. Place the other end of the hose assembly in an oil

collector (Fig. 43, item3).

! Test oil starts to run through the hose assembly

immediately after releasing the shut-off valve. Al-

ways place the end of the hose assembly in the oil

collector beforehand.

5. Open the shutoff valve (Fig. 43, item1) and let the

test oil drain until the test oil tank is completely

empty.

Loading...

Loading...