Apr. 2007

2

-47

DSC48

417W291A

417W290A

417W289A

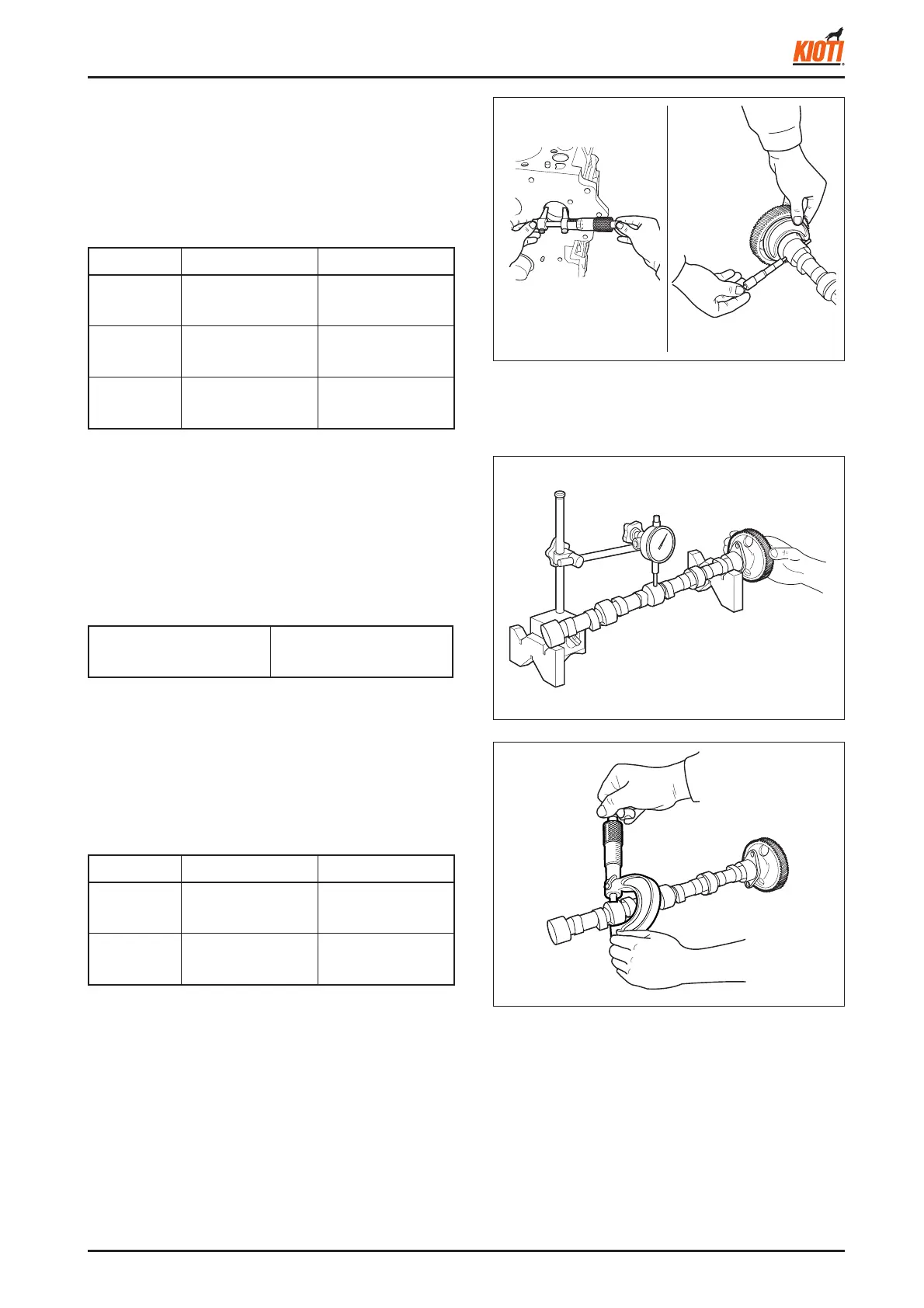

► CAMSHAFT OIL CLEARANCE

1. Measure the I.D. of the camshaft bore on the crank-

case with an inside micrometer.

2. Measure the O.D. of the camshaft journal with an out-

side micrometer.

3. If the clearance exceeds the allowable limit, replace the

shaft.

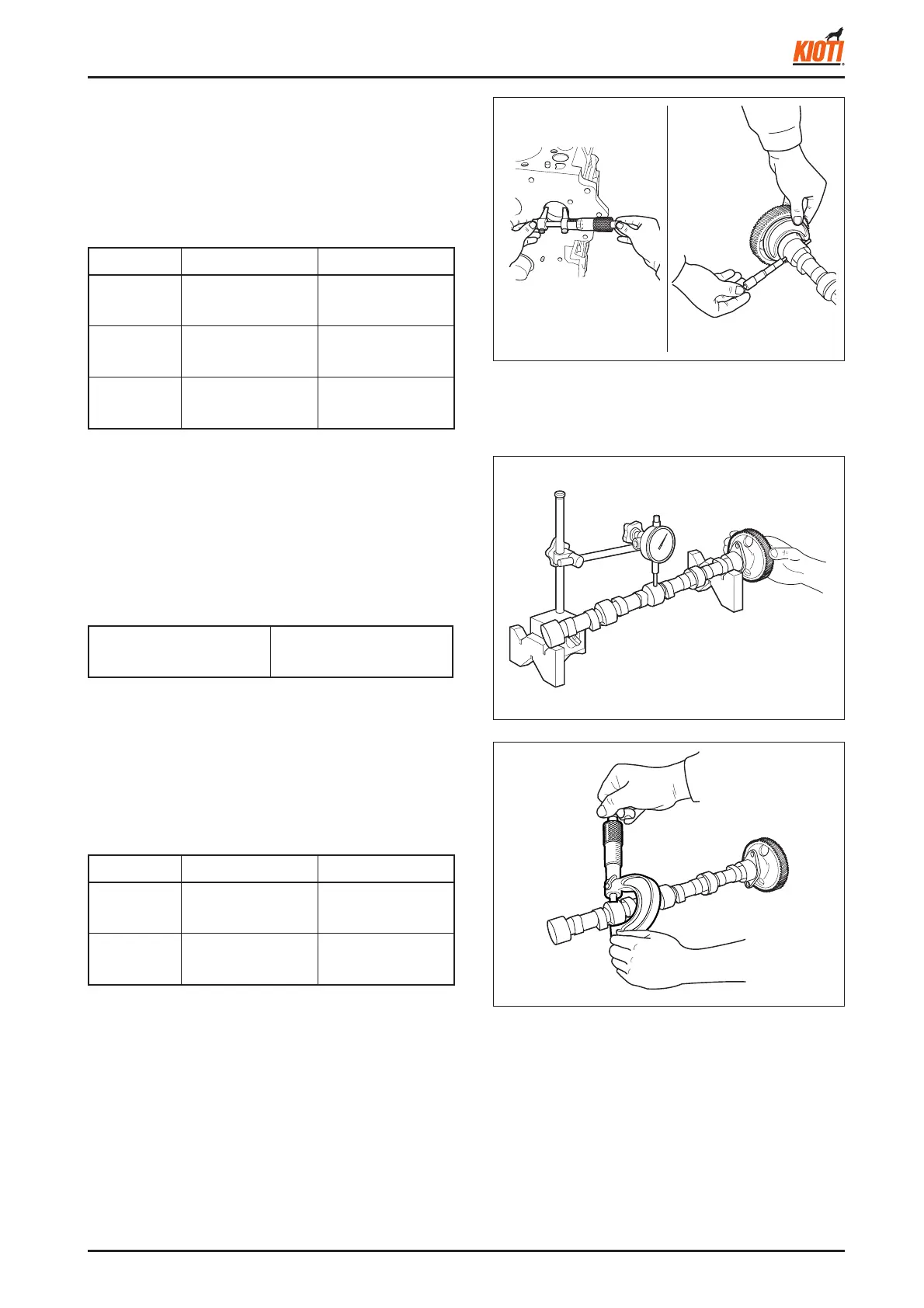

► CAMSHAFT ALIGNMENT

1. Support the camshaft's both end journals with V blocks

on a fl at table. And set a dial indicator with its tip on the

intermediate journal.

2. Rotate the camshaft on the V block and get the eccen-

tricity (half of the measurement).

3. If the eccentricity exceeds the allowable limit, replace

the camshaft.

► CAM HEIGHT

1. Measure the height of the camshaft lobes at their larg-

est O.D. with an outside micrometer.

2. If the measurement is less than the allowable limit, re-

place the camshaft.

Factory spec. Allowable limit

Oil clearance

0.050 ~ 0.091 mm

0.002 ~ 0.004 in.

0.15 mm

0.006 in.

Journal O.D.

39.934 ~ 39.950 mm

1.572 ~ 1.573 in.

-

Bore I.D.

40.000 ~ 40.025 mm

1.575 ~ 1.576 in.

-

Allowable limit

0.05 mm

0.002 in.

Factory spec. Allowable limit

(IN.)

33.59 mm

1.322 in.

33.54 mm

1.320 in.

(EX.)

33.69 mm

1.326 in.

33.64 mm

1.324 in.

Loading...

Loading...