2

-50

Apr. 2007

DSC48

417W298A

D. CRANKSHAFT

► FLYWHEEL DEFLECTION AND CRANKSHAFT

END PLAY

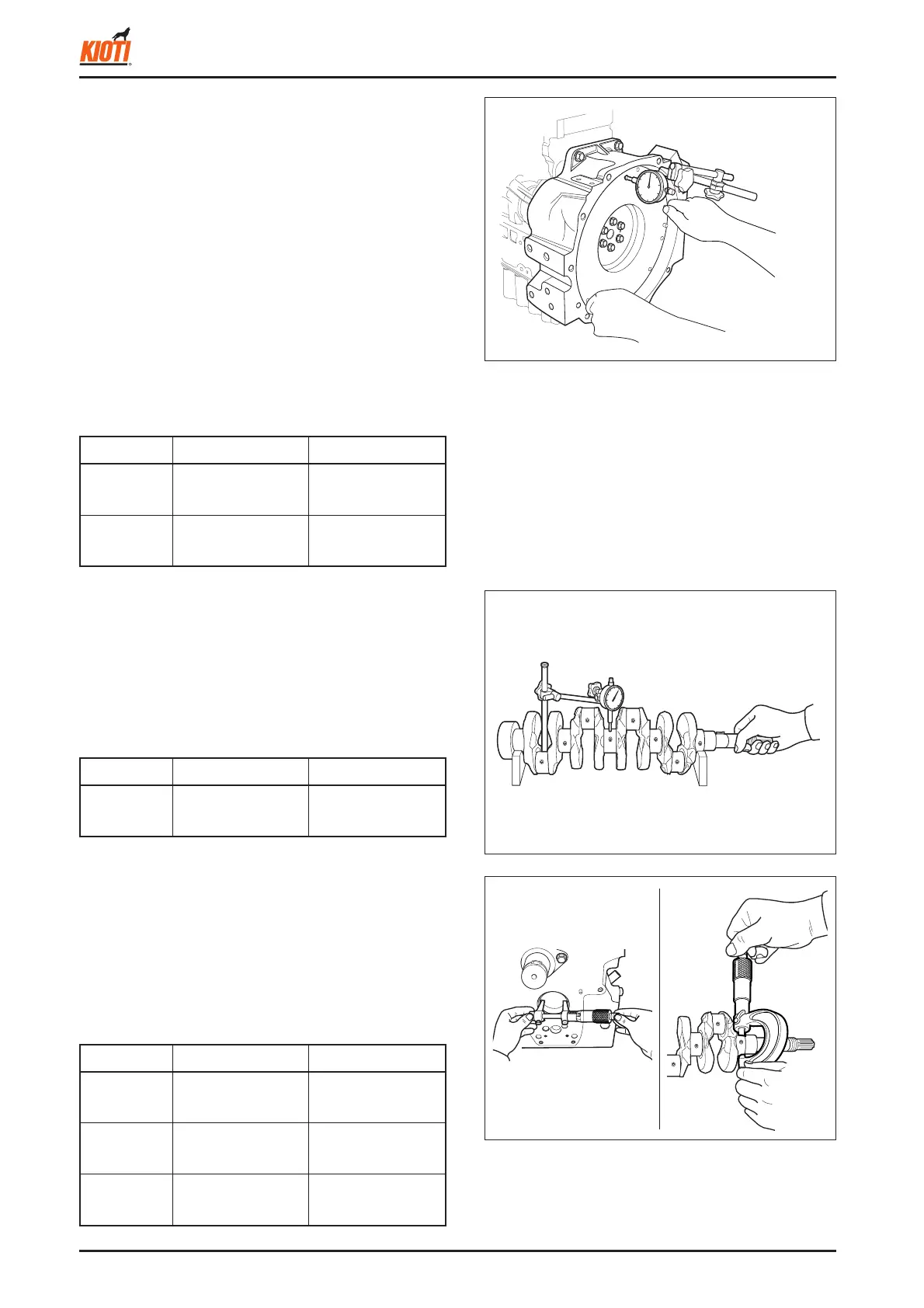

1. Set a dial indicator's top on the rear friction face of the

fl ywheel near the edge.

2. Turn the fl ywheel and measure the defl ection or uneven

wear.

3. If the measurement exceeds the allowable limit, re-

move the fl ywheel and check the mating faces of the

crankshaft and fl ywheel.

4. If the mating faces are cracked or excessively worn,

resurface or replace the fl ywheel.

5. Move back and forth the crankshaft and flywheel to

their ends. And measure the end play.

6. If the play exceeds the allowable limit, replace the side

bearing.

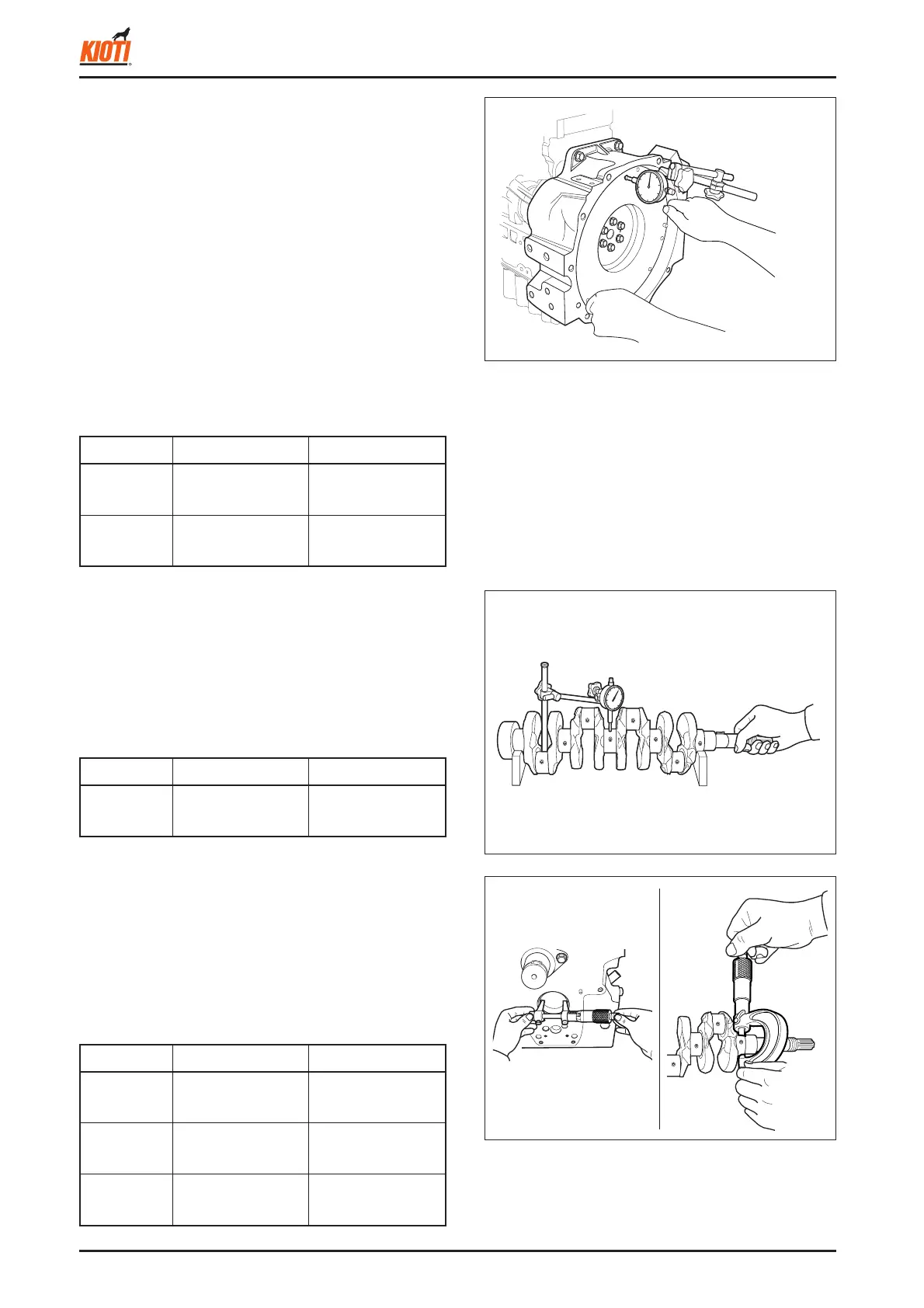

► CRANKSHAFT ALIGNMENT

1. Support the camshaft's both end journals with V blocks

on a fl at table. And set a dial indicator with its tip on the

intermediate journal.

2. Rotate the crank shaft on the V block and get the ec-

centricity (half of the measurement).

3. If the misalignment exceeds the allowable limit, replace

the crankshaft.

417W299A

1

1

10

9

417W2A0A

► CRANKSHAFT JOURNAL AND BEARING 1 OIL

CLEARANCE

1. Measure the I.D. of the crankshaft bearing 1 with an

inside micrometer.

2. Measure the O.D. of the crankshaft journal with an out-

side micrometer.

3. If the clearance exceeds the allowable limit, replace the

crankshaft bearing 1.

Factory spec. Allowable limit

Valve stem

clearance

-

0.05 mm

0.002 in.

End play

0.15 ~ 0.31 mm

0.006 ~ 0.012 in.

25.05 mm

0.986 in.

Factory spec. Allowable limit

Defl ection -

0.02 mm

0.001 in.

Factory spec. Allowable limit

Clearance

0.040 ~ 0.118 mm

0.002 ~ 0.005 in.

0.20 mm

0.008 in.

Journal O.D.

51.921 ~ 51.940 mm

2.044 ~ 2.045 in.

-

Bearing 1 I.D.

51.980 ~ 52.039 mm

2.046 ~ 2.049 in.

-

Loading...

Loading...