Apr. 2007

2

-51

DSC48

417W2A3A

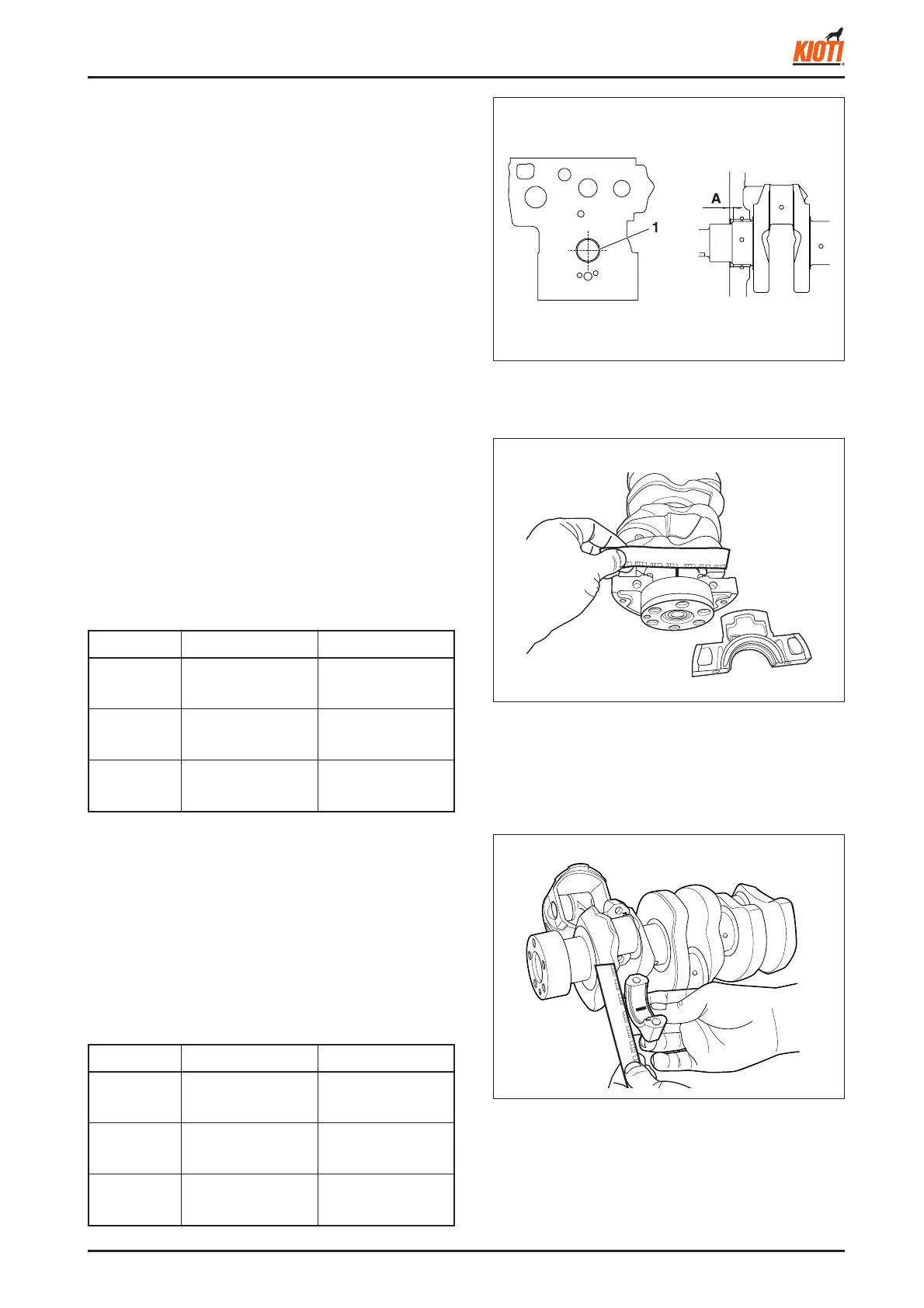

► OIL CLEARANCE BETWEEN CRANKPIN AND

CONNECTING ROD BIG END BEARING

1. Put a strip of plastigage lengthwise in the center of the

crankpin.

2. Install the connecting rod cap and tightened the bolt to

the specifi ed torque. Remove the cap again.

3. Measure the amount of fl attening with the scale and get

the oil clearance.

4. If the clearance exceeds the allowable limit, replace the

bearing.

417W2A1A

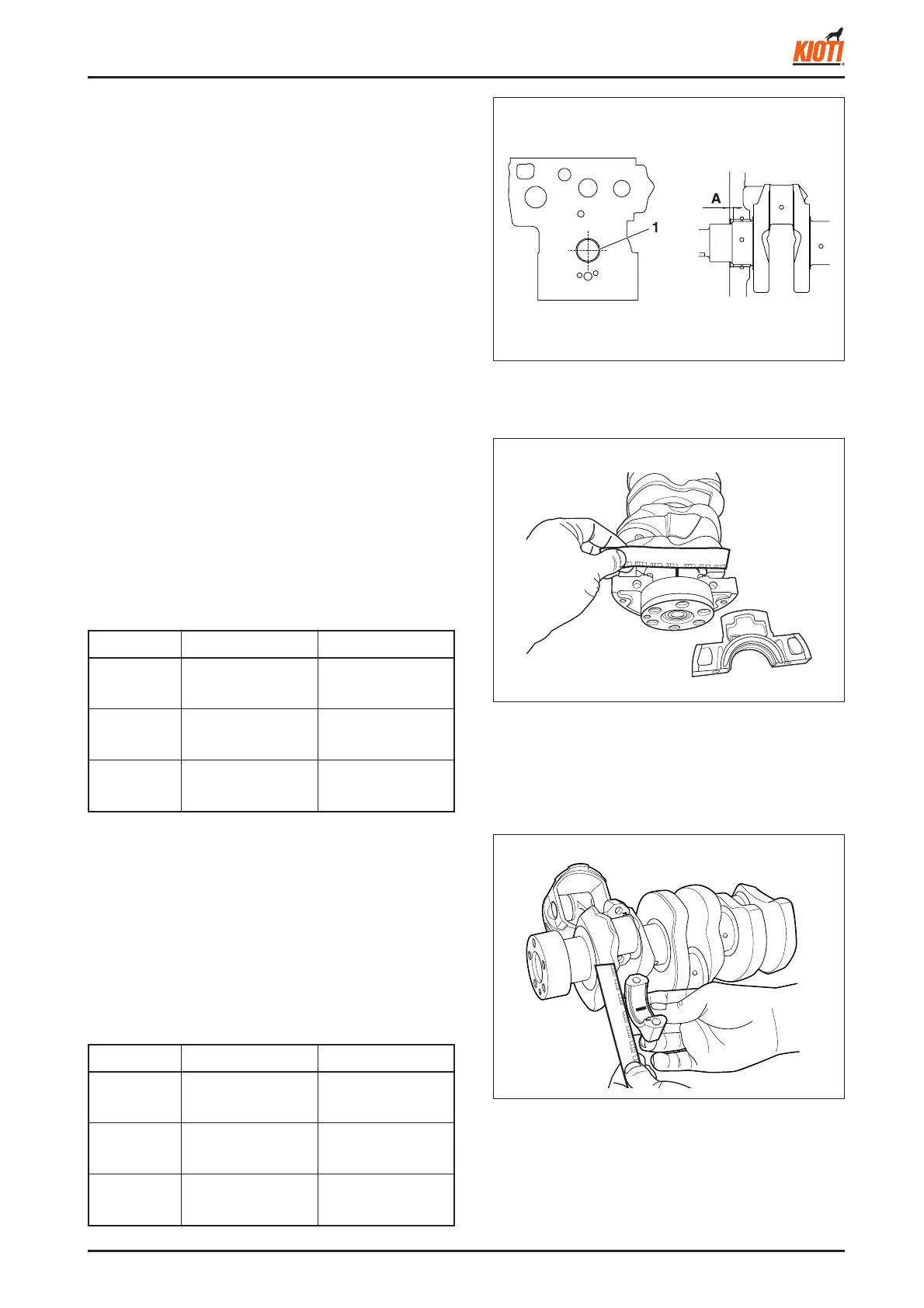

► REPLACING CRANKSHAFT BEARING 1

1. Press out the crankshaft bearing 1 using the replacing

tool.

2. Clean the cylinder block bore and crankshaft bearing 1.

And apply engine oil to them.

3. Install the crankshaft bearing 1 to the cylinder block so

that its seam faces the exhaust manifold side.

(1) Seam

(a) 4.2 ~ 4.5 mm

417W2A2A

► OIL CLEARANCE BETWEEN CRANKSHAFT

JOURNAL AND BEARING 2

1. Put a plastigage lengthwise in the center of the journal.

2. Install the bearing cap and tightened the bolt to the

specifi ed torque. Remove the cap again.

3. Measure the amount of fl attening with the scale and get

the oil clearance.

4. If the clearance exceeds the allowable limit, replace the

bearing.

Factory spec. Allowable limit

Clearance

0.040 ~ 0.104 mm

0.002 ~ 0.004 in.

0.20 mm

0.008 in.

Journal O.D.

51.921 ~ 51.940 mm

2.044 ~ 2.045 in.

-

Bearing 2 I.D.

51.980 ~ 52.025 mm

2.046 ~ 2.048 in.

-

Factory spec. Allowable limit

Oil clear-

ance

0.025 ~ 0.087 mm

0.001 ~ 0.003 in.

0.20 mm

0.008 in.

Crankpin

O.D.

46.959 ~ 46.475 mm

1.849 ~ 1.830 in.

-

Pin bearing

I.D.

47.000 ~ 47.046 mm

1.850 ~ 1.852 in.

-

Loading...

Loading...