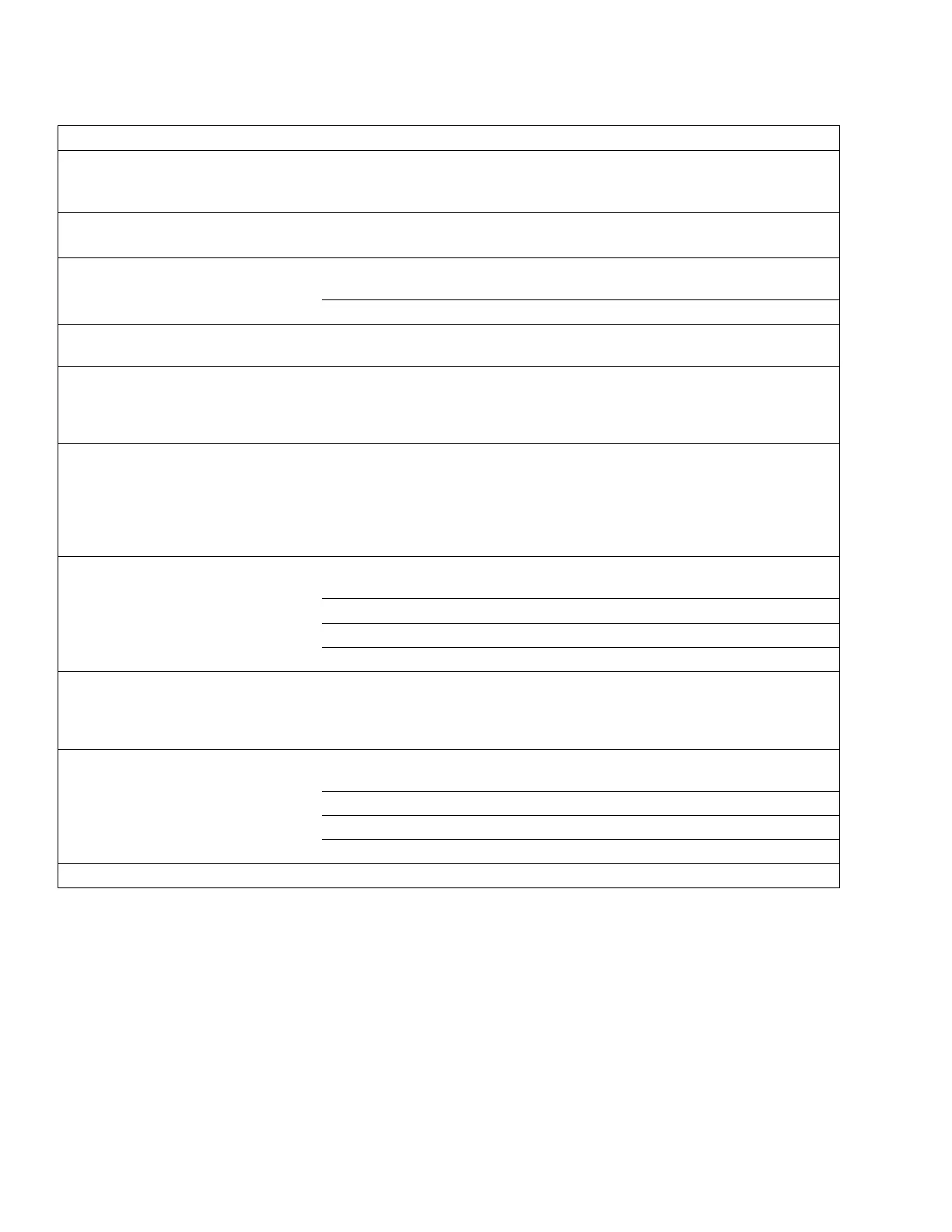

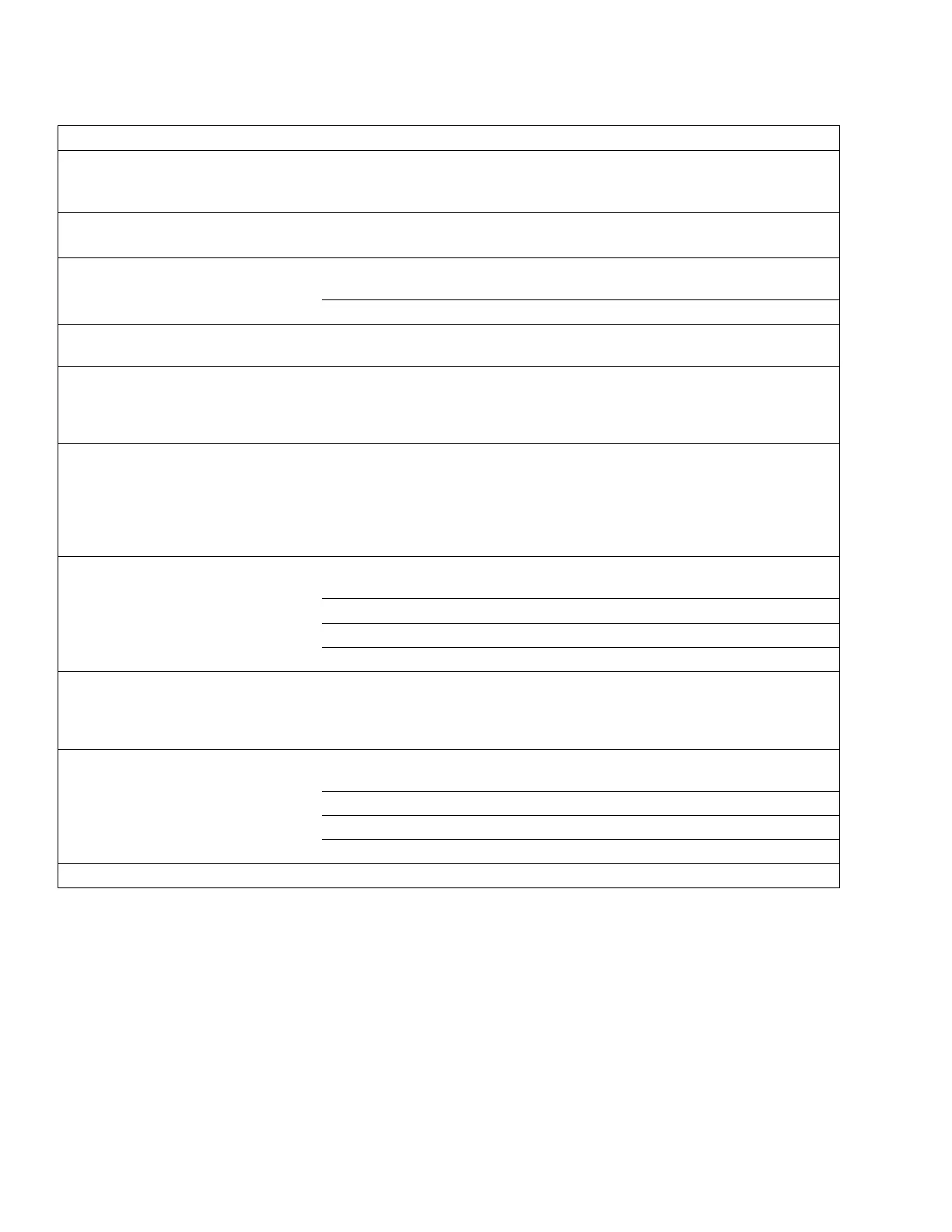

Chapter 12 - Troubleshooting Alarm – Cause – Remedy

200 Apollo Operator’s Manual

Part Number: 90 38 237, 5th edition

Priority Message Cause Remedy

Advisory FAN FAIL Fan for evacuating gases inside the

device is defective.

Workstation must be switched off as

quickly as possible!

1

Call DrägerService.

Caution FG FLOW TOO HIGH Total fresh-gas flow is above 19 L/min. Reduce fresh-gas flow.

Check vaporizer setting.

Caution

Warning

2

FG LOW OR LEAK

3

fresh gas setting too low. Increase fresh-gas flow.

Leak. Repair leak.

Advisory GAS SENSOR FAIL

4

Complete gas measurement system

failure.

Use external gas measuring system.

Call DrägerService.

Warning/

Advisory

GAS MIXER FAIL* Fresh gas measurement is probably

inaccurate or failed.

Switch-over to auxiliary CGO may have

failed.

Use only oxygen as fresh gas and check

total flow meter.

Call DrägerService.

Warning/

Advisory

GAS + VENT FAIL.* Ventilator failed.

Fresh gas measurement is probably

inaccurate or failed.

Switch-over to auxiliary CGO may have

failed.

Patient must immediately be ventilated

manually!

Use only oxygen as fresh gas and check

total flow meter.

Call DrägerService.

Warning HIGH AIRWAY PRESSURE High alarm limit for the airway pressure

has been exceeded.

Ventilation hose kinked. Check hose system and tube.

Stenosis.

Ventilation settings are not correct. Correct the ventilation settings.

Caution INCORRECT FG FLOW Reduced accuracy of fresh-gas flow

measurement.

Reduce fresh-gas flow for each gas to

below 12 L/min.

Check total flow meter.

Call DrägerService.

Caution INSP CO

2 HIGH Soda lime in circle system exhausted. Increase fresh-gas flow.

Replace soda lime.

Leak or fault in breathing system. Replace breathing system.

High ventilation frequencies

5

. Adjust alarm limits if necessary.

Dead space ventilation. Check ventilation settings.

Advisory INSP. FLOW SENSOR FAIL Inspiratory flow sensor is faulty. Replace flow sensor (see page 170).

1. Defective fans in combination with an internal leakage may lead to elevated O2 concentrations inside the workstation.

Risk of fire!

2. The priority of the alarm message depends on the severity of the fresh gas shortage.

3. If the alarms “VT NOT ACHIEVED” or “PINSP NOT ACHIEVED” occur additionally, a fresh gas deficiency in the system is remedied by

entraining ambient air. Monitor concentrations carefully as the breathing gas will be diluted.

4. Displayed in Standby mode only.

5. At high ventilation frequencies, the measured value cannot keep up completely with the gas concentration for reasons due to the system.

* Alarm can be downgraded to specified lower priority or canceled.

Loading...

Loading...