3.7 Address Configuration

A3-31

ME0384-4A

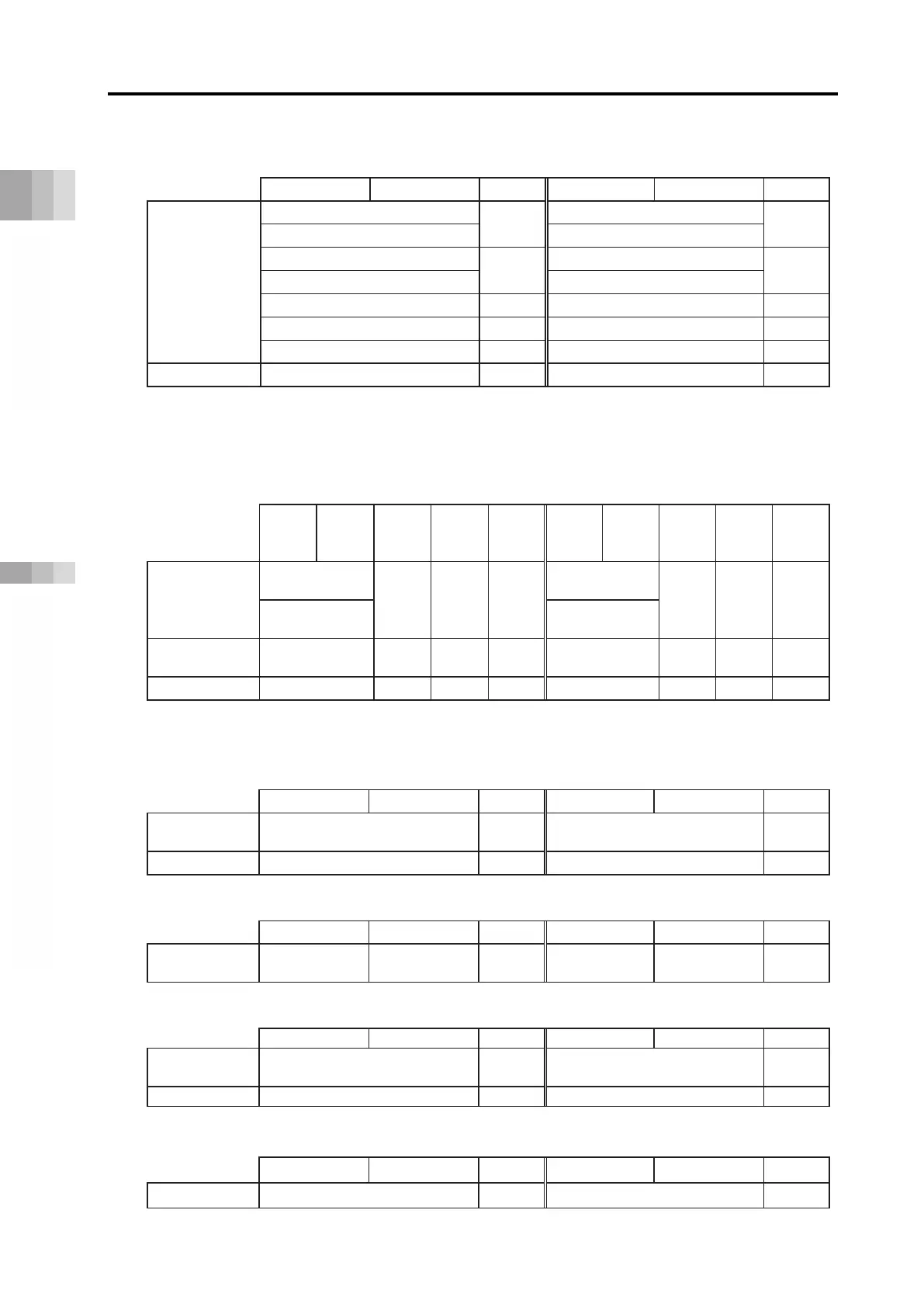

(2) Direct numerical control mode data region configuration

PLC output

each axis input Each axis output

PLC input

High byte Low byte

Word count

High byte Low byte

Word count

Direct

specified

region

Specified position data (L)

*

2

Present position data (L))

*

2

Specified position data (H))

*

Present position data (H))

*

Specified positioning width (L))

*

2

Present current value (L))

*

2

Specified positioning width (H))

*

Present current value (H))

*

(Note 1)

Specified acceleration/deceleration

Pushing current limit value

*(L) is the low word of a 2-word datum while (H) is the high word of a 2-word datum.

Note 1:

The present current value should be the command current value for the stepper motor and be the

feedback current value for the AC servomotor (including AC servomotor connected to SCON-CB).

(3) Simple direct mode and positioner 1 mode data region configuration

PLC output ⇒ each axis input

Each axis output ⇒ PLC input

High

byte

Low

byte

Word

count

direct

1 mode

High

byte

Low

byte

Word

count

direct

1 mode

Position data

specified

region

Specified

position data (L)

2 ○ x

*

Present position

data (L)

2 ○ ○

Specified

position data (H)

Present position

data (H)

Position

specified region

1 ○ ○

1 ○ ○

* Positioner 1 mode does not use the position data specified region (PLC ⇒ each axis input),

but it is occupied as a data region.

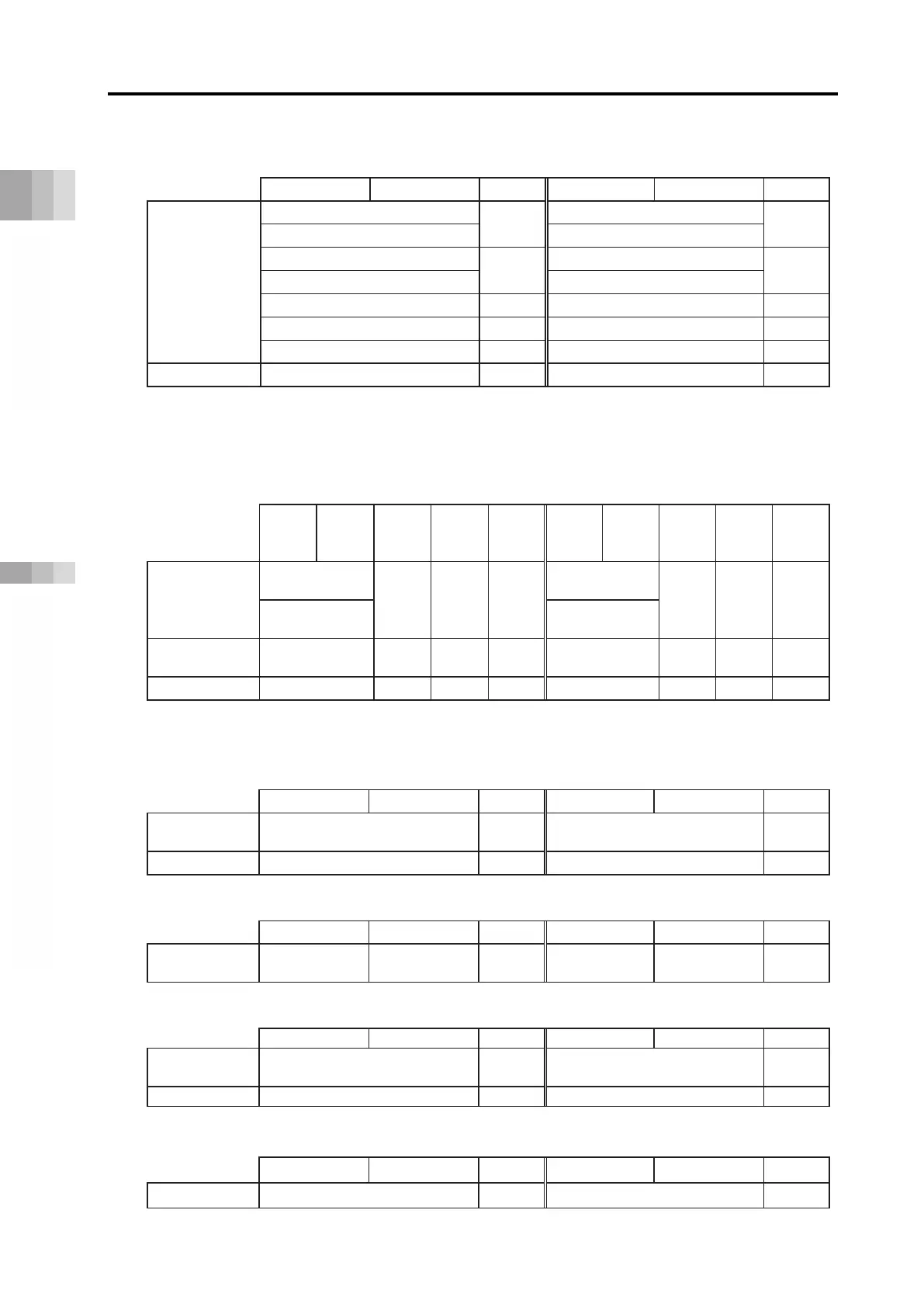

(4) Positioner 2 mode data region configuration

Position

specified region

Command position No. 1 Completed position No. 1

Control signal region

Control signal 1 Status signal 1

(5) Positioner 3 mode data region configuration

Control signal region

Control signal

1 Status signal

1

(6) Positioner 5 mode data region configuration

Position

specified region

Command position No. 1

Present position data

(0.1 mm increments)

1

(7) EC connection unit data region configuration

High byte Low byte

Word count

High byte Low byte

Word count

Control signal (for four axes).

Status signal (for four axes)

Loading...

Loading...