4.4 Address Configuration

B4-47

ME0384-4A

Chapter 4 Network Configuration

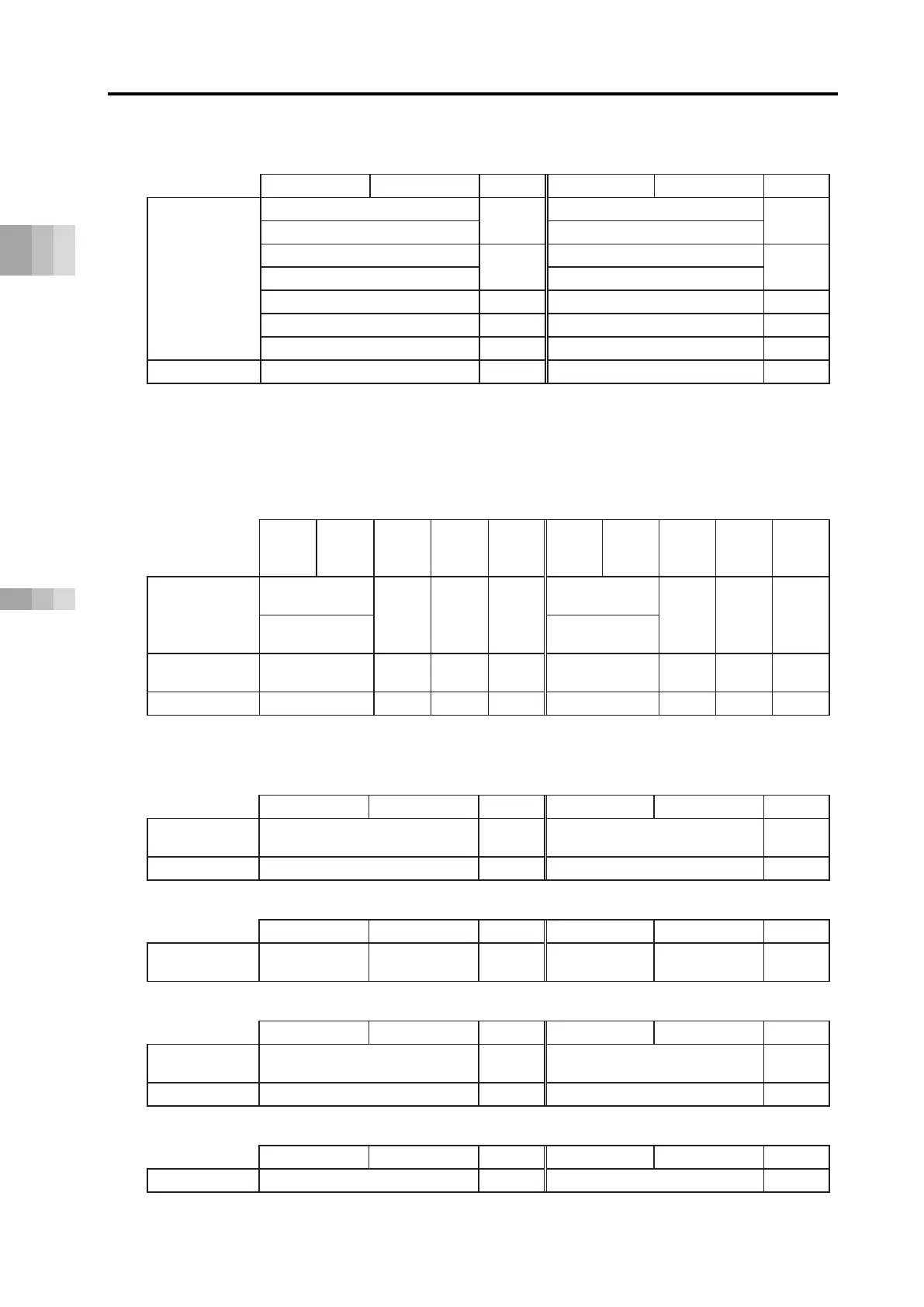

(2) Direct numerical control mode data region configuration

PLC output

each axis input Each axis output

PLC input

Direct

specified

region

Specified position data (L)

*

2

Present position data (L))

*

2

Specified position data (H))

*

Present position data (H))

*

Specified positioning width (L))

*

2

Present current value (L))

*

2

Specified positioning width (H))

*

Present current value (H))

*

Specified acceleration/deceleration

Pushing current limit value

*(L) is the low word of a 2-word datum while (H) is the high word of a 2-word datum.

Note 1: The present current value should be the command current value for the stepper motor

and be the feedback current value for the AC servomotor (including AC servomotor

connected to SCON-CB).

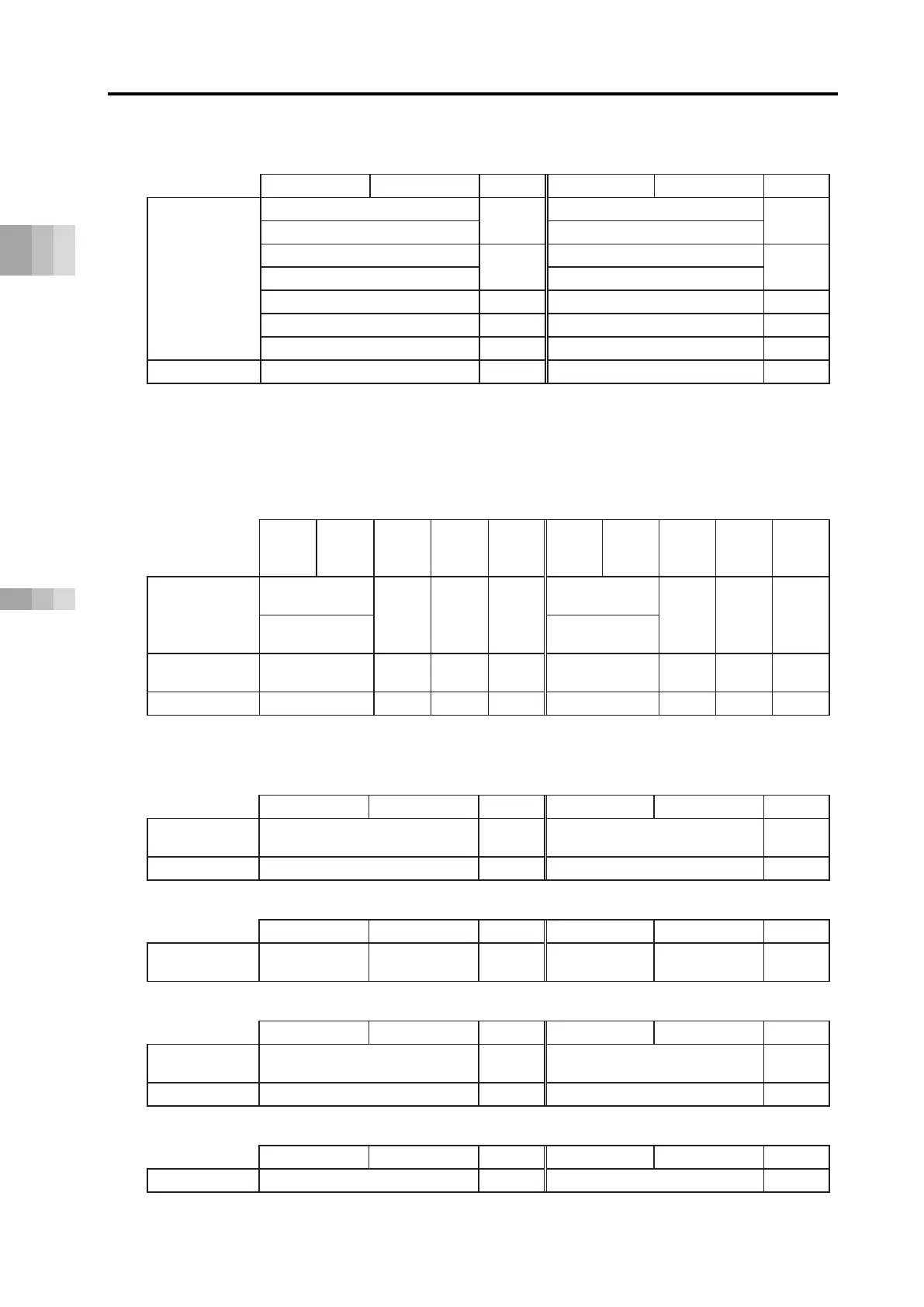

(3) Simple direct mode and positioner 1 mode data region configuration

PLC output ⇒ each axis input

Each axis output ⇒ PLC input

High

byte

Low

byte

Word

count

direct

1 mode

High

byte

Low

byte

Word

count

direct

1 mode

Position data

specified

region

Specified

position data (L)

2 ○ x

*

Present position

data (L)

2 ○ ○

Specified

position data (H)

Present position

data (H)

Position

specified region

1 ○ ○

1 ○ ○

* Positioner 1 mode does not use the position data specified region (PLC ⇒ each axis input), but

it is occupied as a data region.

(4) Positioner 2 mode data region configuration

Position

specified region

Command position No. 1 Completed position No. 1

(5) Positioner 3 mode data region configuration

High byte Low byte

Word count

High byte Low byte

Word count

Control signal region

Control signal

1 Status signal

1

(6) Positioner 5 mode data region configuration

Position

specified region

Command position No. 1

Present position data

(0.1 mm increments)

1

(7) Data Domain Construction of EC Connector Unit

Control signal (for four axes)

Control signal (for four axes)

Loading...

Loading...