1.1 Periodic Inspection

C1-2

ME0384-4A

Chapter 1 Maintenance and Inspection

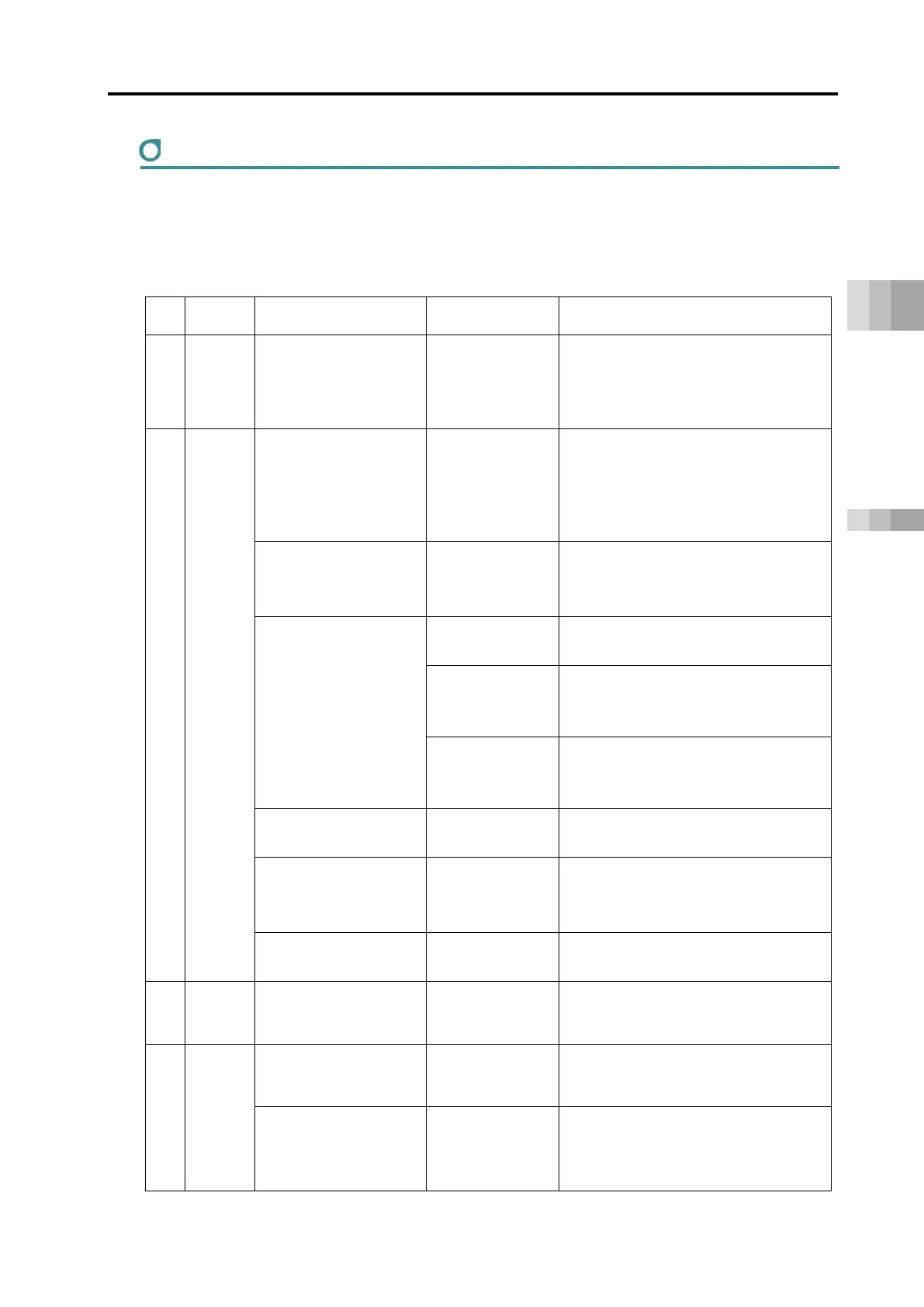

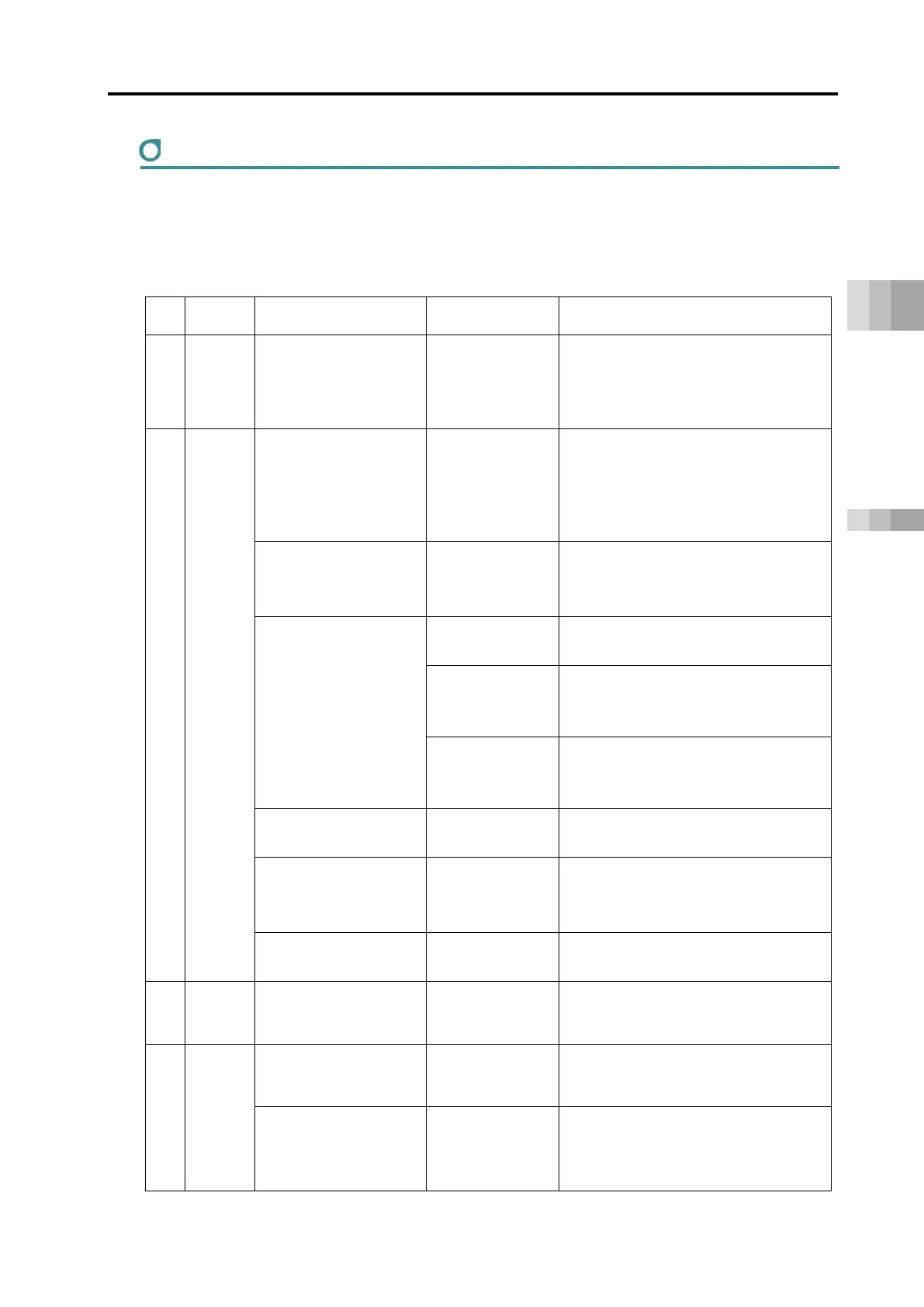

Periodic inspection items

The RCON systems contain electronic components that may degrade due to the operating

environment and require periodic inspection.

It is standard to conduct periodic inspection once every 6 months to one year, but the interval

should be shortened in accordance with operating environment.

No.

Inspection details

Countermeasures

1

Power

supply

power supply terminal

block to check that the

voltage fluctuation is

within the reference range

Within voltage

fluctuation range

24 V ±10%

Adjust so that the power supply

voltage falls within the judgment

criteria.

2

Operating

environment

Ambient temperature

(If used in a panel, the

panel temperature is

the ambient

temperature)

0 to 55°C

Measure the operating temperature

with a thermometer and adjust the

environment so that it falls within the

ambient operating temperature.

However, simple absolute units and

SCON controllers are 0 to 40°C.

Operating humidity

(Panel humidity if using

in a panel)

95% RH or less,

non-condensing

Measure the operating humidity with a

hygrometer and adjust the

environment so that it falls within the

ambient operating humidity.

No corrosive or

flammable gas

Check with an odor or gas sensor.

No splatters of

water, oil, or

chemicals

Remove and shield.

No accumulated

dust, debris, salt,

or metal powder

Remove and shield.

Directly exposed to

sunlight?

Out of direct

sunlight

Shield.

Subjected to direct

vibrations or impacts?

and shock-resistant

specifications should

Install a cushion, etc., for vibration

damping and shock resistance.

Close to a noise

source?

None

Move the noise source further away or

take shielding countermeasures.

3

Mounting

status

DIN rail

No slack in unit

mounting

Re-attach and lock.

4

Connection

status

Units firmly connected?

The connector

should be

tightened firmly

Tighten so that it is no longer loose.

Cable between simple

absolute unit and

unit securely inserted?

Insert completely Insert again.

Loading...

Loading...