3-56 INSPECTIONS / GENERAL INSPECTION TASKS

ICON A5 / MAINTENANCE MANUAL CHANGE C2

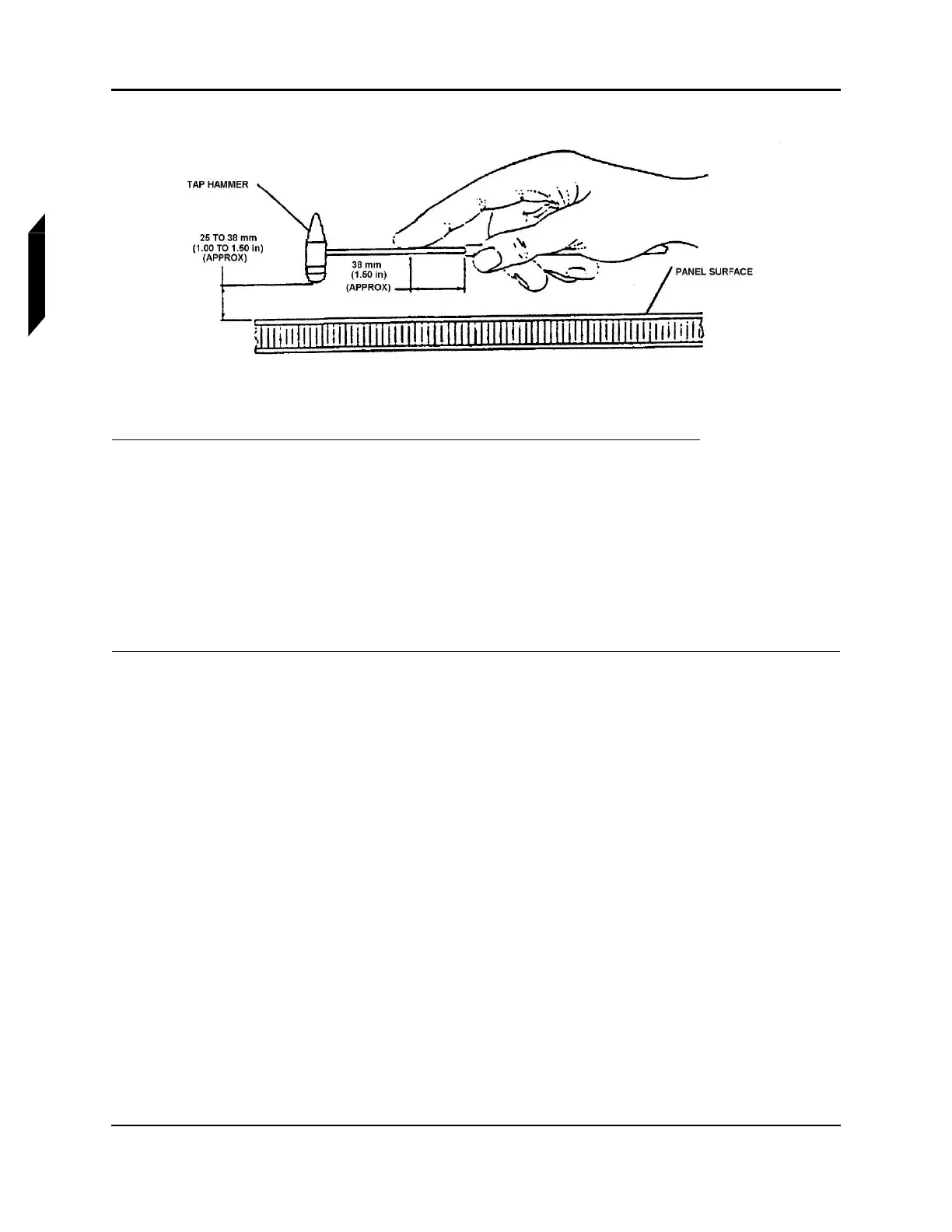

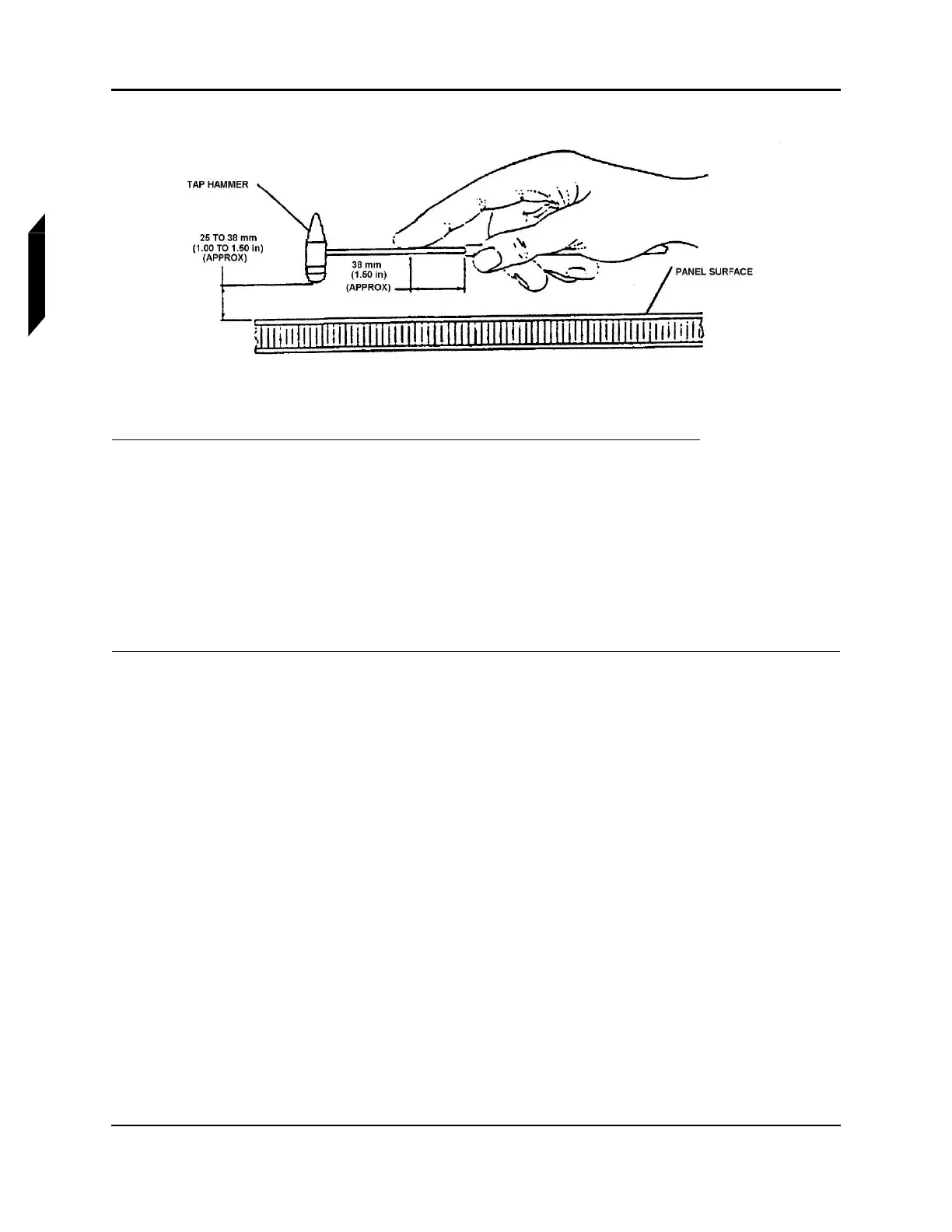

FIGURE 3-4

MANUAL TAP TEST PROCEDURE.

1. The inspection area should be relatively free from noise and distraction. A representative sample

of the part/structure being inspected must be present and used as a reference.

2. Tapping on the part/structure must be done lightly to avoid damage during the inspection

process. Recommended tapping stroke is approximately 1.0 inches to 1.5 inches.

3. Tap the reference sample lightly approximately 3-5 times per second in both the good and iden-

tified potential defect area to note the audible difference.

4. Systematically inspect the part/structure tapping approximately every 0.5-1.0 inch and returning

to the reference sample periodically to note any audible difference.

VERIFICATION METHOD:

If a defect is found, tap outward from the center of the defect until a change in sound is detected. Mark

the area of change and repeat until the entire defect area is identified. Contact ICON for repair instruc-

tions.

RELATED INFORMATION:

"Condition and 100-Hour Inspection—Wings" on page 3-11

"Condition and 100-Hour Inspection—Forward Fuselage and Hull" on page 3-16

"Inspect Empennage Skin" on page 12-4

"Wing Skins Delaminate/Voids" on page 17-4

Loading...

Loading...