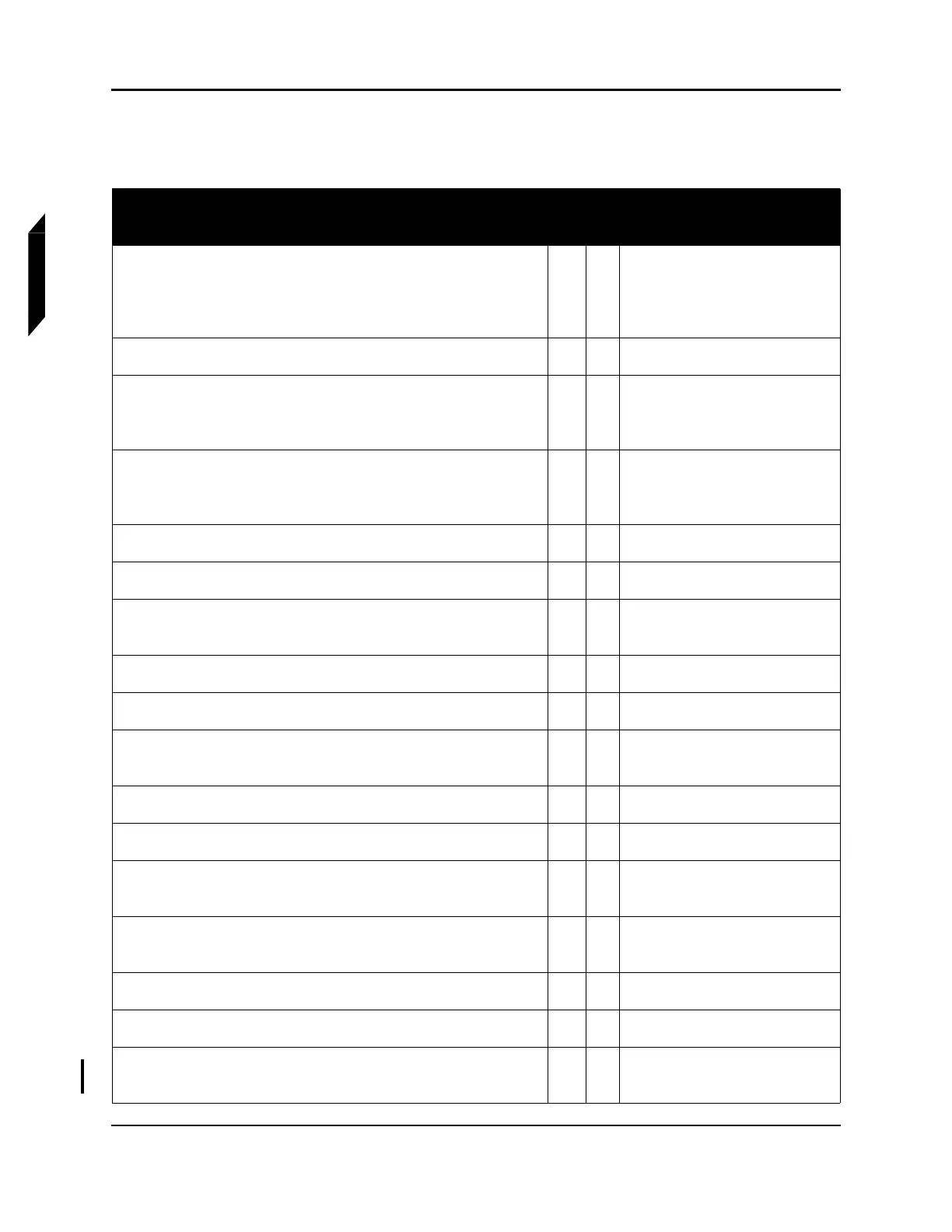

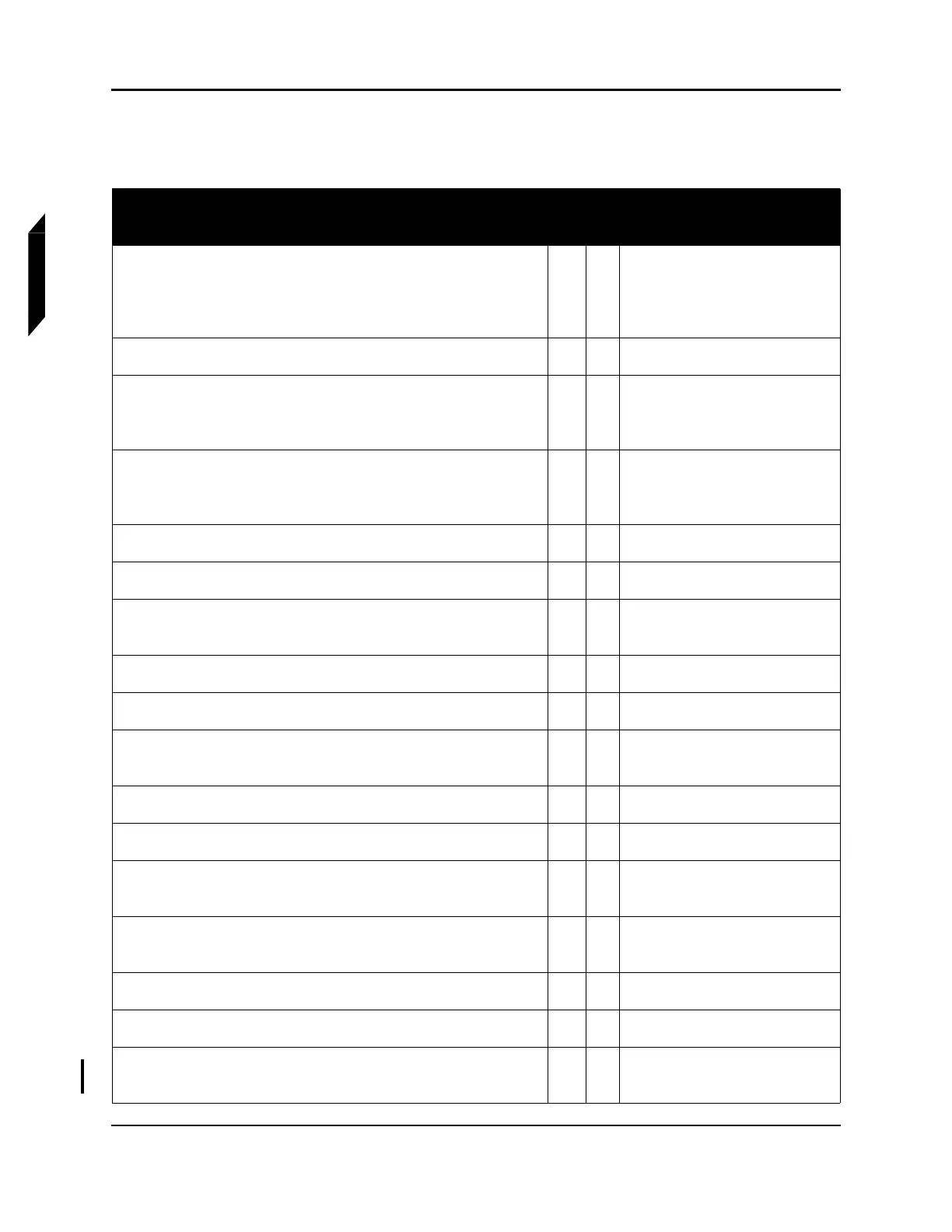

3-14 INSPECTIONS / CONDITION INSPECTIONS AND 100-HOUR INSPECTIONS

ICON A5 / MAINTENANCE MANUAL CHANGE C2

3.3.4 Condition and 100-Hour Inspection—Landing Gear

Correct all unsatisfactory items prior to flight

S=Satisfactory, U=Unsatisfactory

S U Comments

Check for rigging of all components, extended and

retracted (See “Check Landing Gear Extended Position”

on page 14-5.)(See “Check Landing Gear Retracted

Position” on page 14-6.)

Test/check indicator lights

Perform retraction/extension, note and investigate

anything unusual (See “Retraction and Extension Time” on

page 14-12.)

Inspect struts/trunnions/pushrods/bellcranks/actuator for

attachment (See “Main Landing Gear Inspection” on page

14-8.)

Inspect spring gear legs for cracks

Check all bushings/bearings for wear/free play

Check composite structure near mounts for

cracks/disbonds

Inspect tires for cracks, wear, and serviceability

Check wheel bearings for smooth operation

Check tire pressure (See “Tire Inflation Pressures” on

page 2-25.)

Brake pads within limits (replacement recommended)

Check brake disks for wear (min thickness 2.8mm)

Check radial play between disc and internal rim per

Berringer Maintenance Manual

Check brake fluid level (use only fluid that meets

MIL-PRF-83282)

Check brake hydraulic lines for leaks and security

Test toe brake pedals for sponginess

Check rigging of pedals (See “General Brake Line

Termination Procedure” on page 14-29.)

Loading...

Loading...