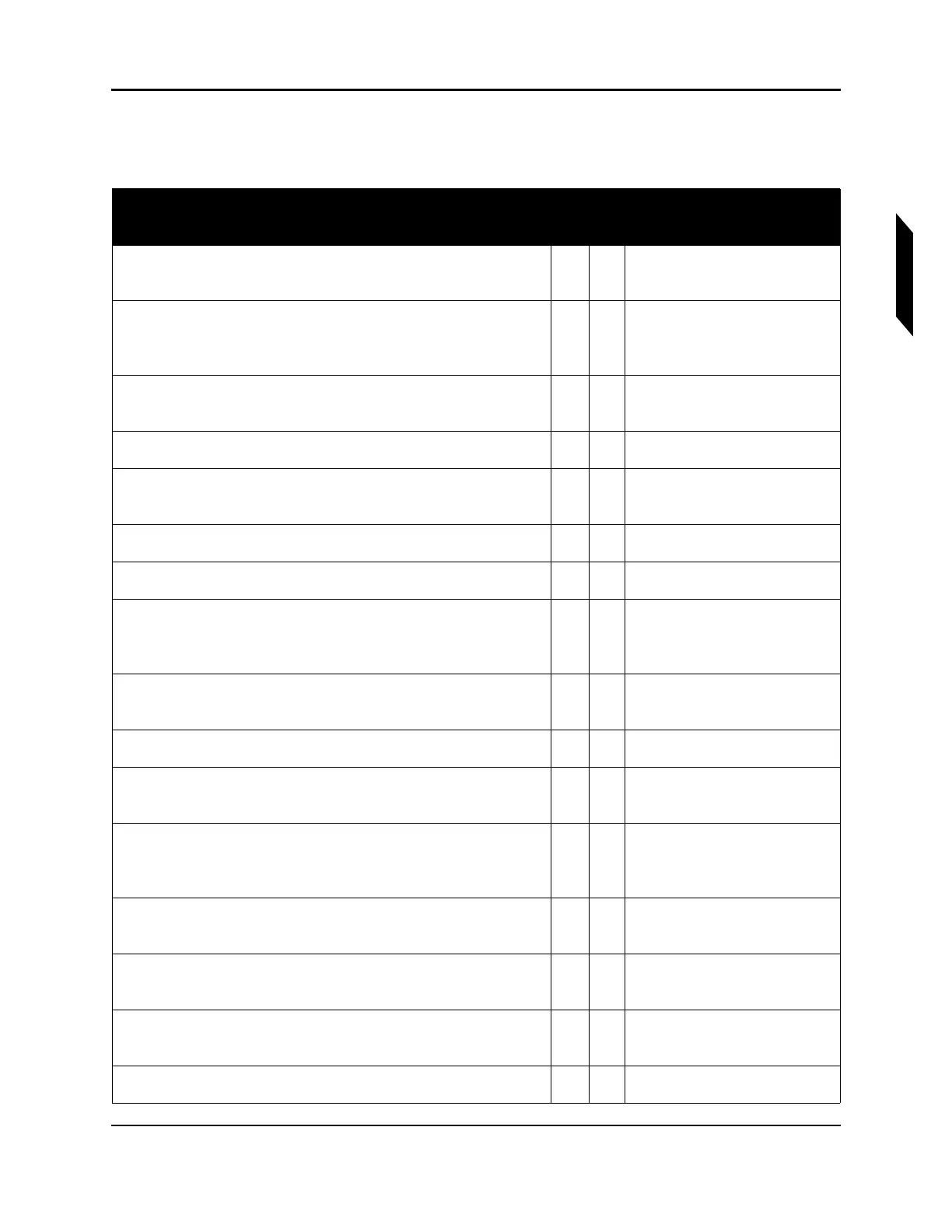

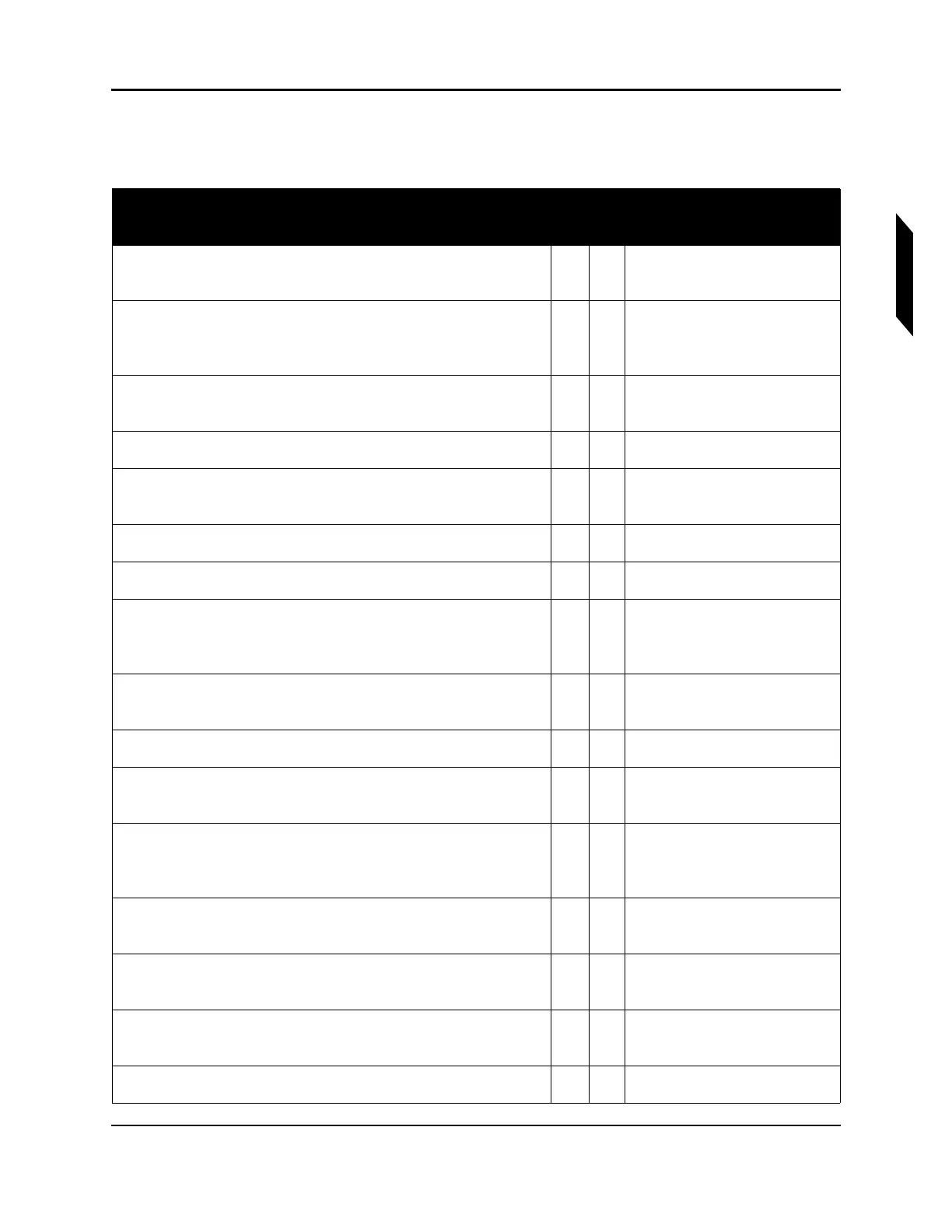

INSPECTIONS / CONDITION INSPECTIONS AND 100-HOUR INSPECTIONS 3-21

CHANGE C2 ICON A5 / MAINTENANCE MANUAL

3.3.8 Condition and 100-Hour Inspection—Engine and Propeller

Correct all unsatisfactory items prior to flight

S=Satisfactory, U=Unsatisfactory

S U Comments

Inspect engine per Rotax 912iS Maintenance Manual’s

maintenance schedule

Inspect engine mount for wear, cracking, missing paint,

general condition. See “Inspect Engine Mount” on page

16-30.

Check engine mount attachments (10 places) are secure.

See “Inspect Engine Mount” on page 16-30.

Check for oil leaks from line fittings and oil tank drain valve

Check firewall for condition and coverage (gaps between

airframe and firewall)

Check oil tank/mounting brackets for security

Inspect oil cooler and radiator for leaks and condition

Inspect throttle control for proper travel and security (See

“Inspect Throttle Control for Proper Travel and Security”

on page 16-32.)

Check exhaust system for attachment, cracks, general

condition

Clean engine air filter

Check cowling for cracks and condition and security of

fasteners. See “Install Engine Cowlings” on page 16-16.

Inspect propeller/hub/extension/fan per Sensenich 3B0R5

Installation Instructions, rev-a8 and verify that hardware is

secure

Remove spinner dome (See “Remove Spinner Dome” on

page 16-105.)

Torque propeller bolts per Sensenich 3B0R5 Installation

Instructions, rev-a8

Reinstall spinner dome (See “Install Spinner Dome” on

page 16-106.)

Check security and condition of engine grounding wires

Loading...

Loading...