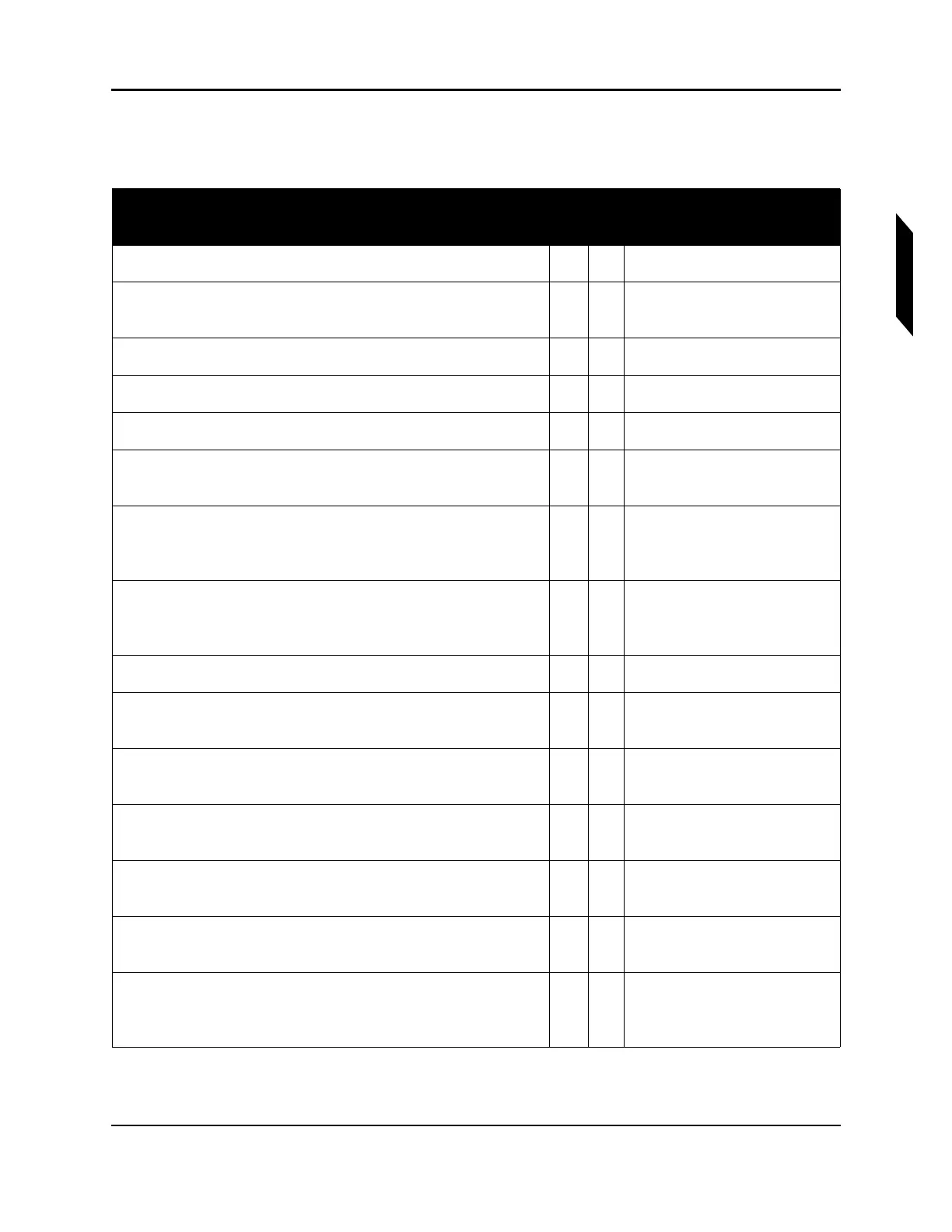

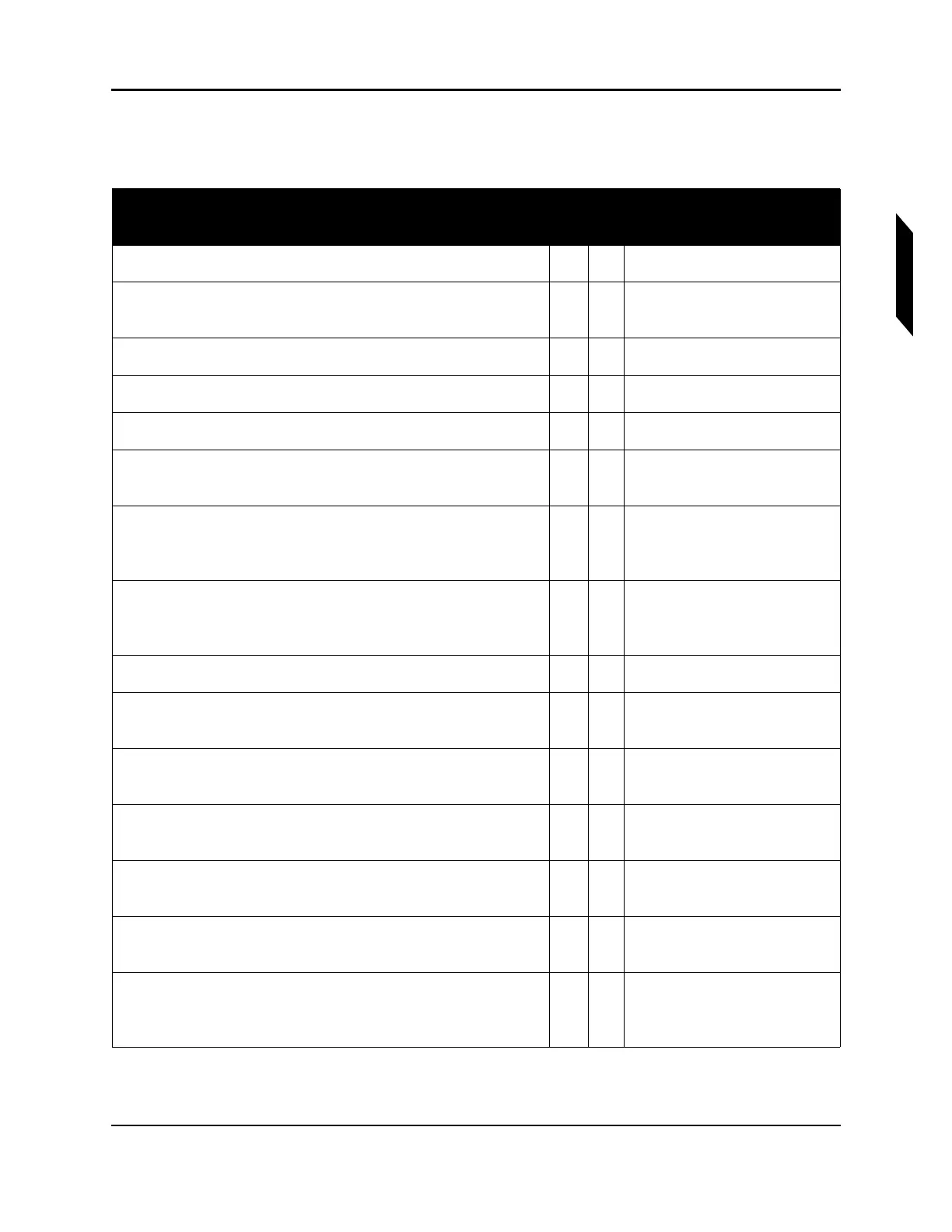

INSPECTIONS / CONDITION INSPECTIONS AND 100-HOUR INSPECTIONS 3-23

CHANGE C2 ICON A5 / MAINTENANCE MANUAL

3.3.9 Condition and 100-Hour Inspection—Avionics and Electrical

Correct all unsatisfactory items prior to flight

S=Satisfactory, U=Unsatisfactory

S U Comments

Battery, load test, free of corrosion, secure

Perform ELT inspection/functional check per FAR 91.207.

See “ELT Inspection and Function Check” on page 13-44.

Inspect antenna mount and wiring for security

Check wires to battery ground

Inspect radio/leads/wires for attachment and security

Inspect wiring instrument panel for attachment and

security

Check bilge pump for function, clear of debris.

See “Check Bilge Pump Function” on page 6-42. See

“Bilge Pump Debris Removal” on page 7-6.

Check wiring harness for chafing/security/condition.See

“Inspect, Repair, and Secure Wiring Harness with Signs of

Chafing” on page 6-34.

Check for wire/connector strains

Calibrate AOA pressure transducer. See “Calibrate AOA

Pressure Transducer” on page 13-25.

Verify regulator B fan is operating with master power

turned on

Inspect regulator B wires for browning near connector.

See “Inspect Regulator Wires” on page 16-84.

Inspect regulator A wire for browning near connector. See

“Inspect Regulator Wires” on page 16-84.

Inspect Rotax fuse box for blown fuses and correct sized

fuses are installed

Inspect overhead panel for blown fuses and correct sized

fuses are installed.

See “Replace Overhead Console Fuses” on page 13-18.

Loading...

Loading...