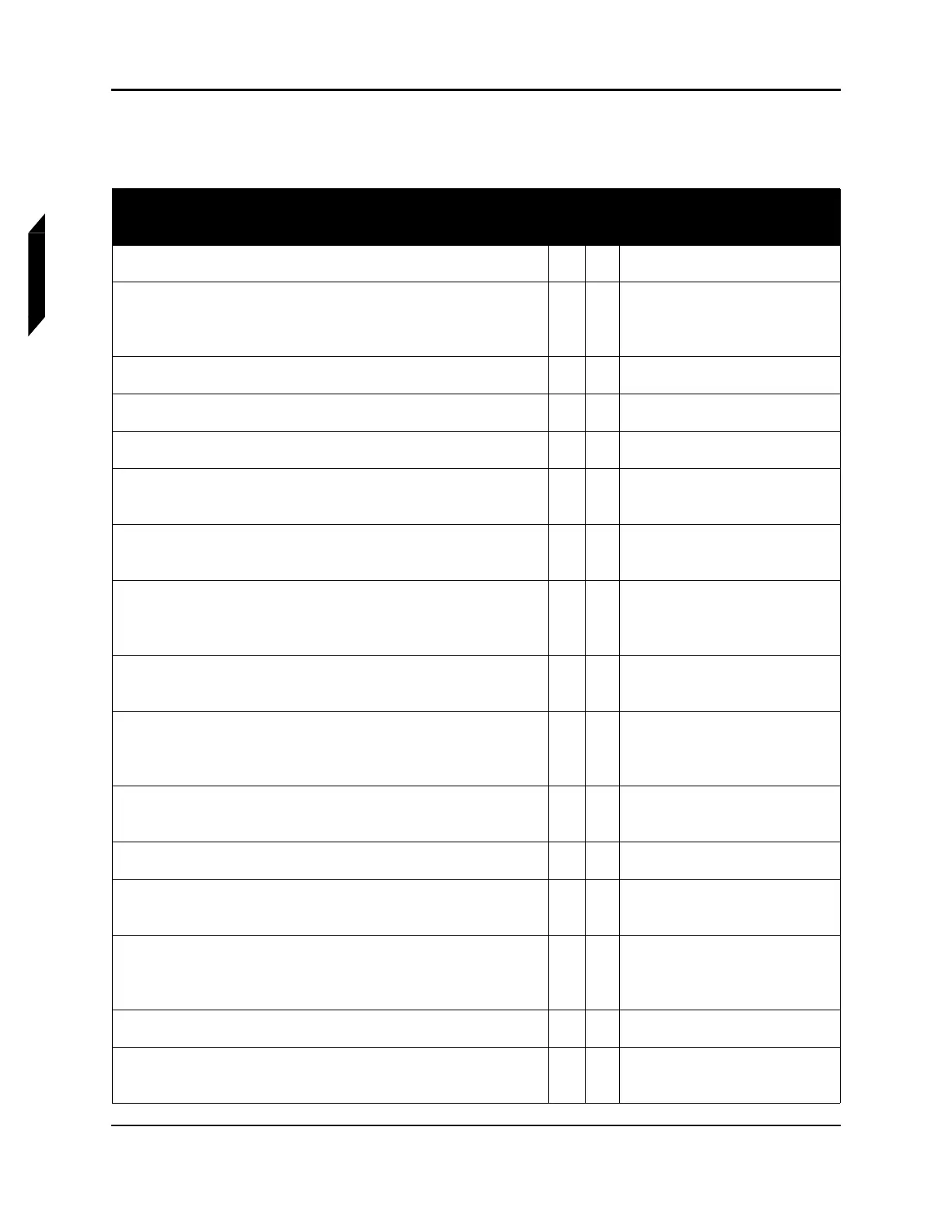

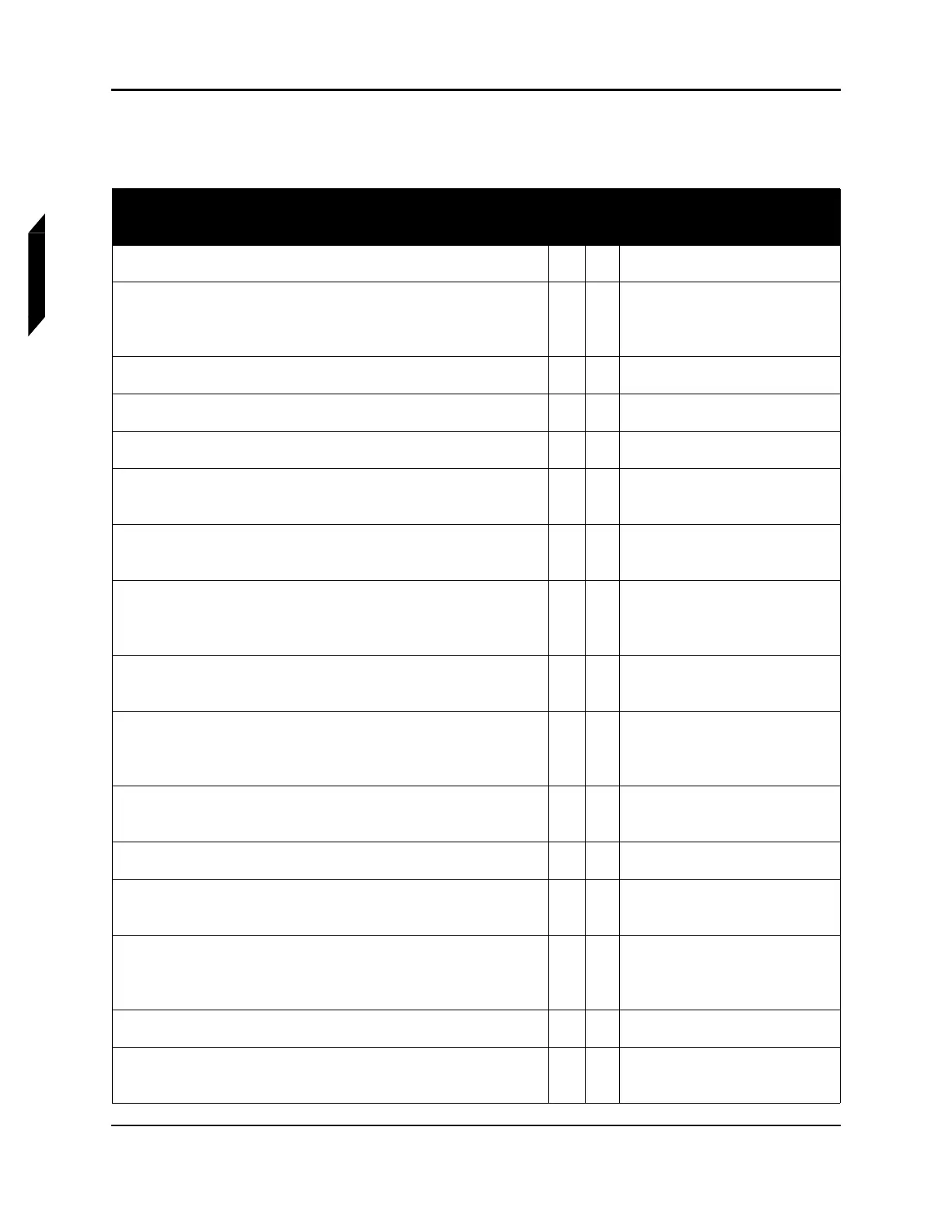

3-16 INSPECTIONS / CONDITION INSPECTIONS AND 100-HOUR INSPECTIONS

ICON A5 / MAINTENANCE MANUAL CHANGE C2

3.3.5 Condition and 100-Hour Inspection—Forward Fuselage and Hull

Correct all unsatisfactory items prior to flight

S=Satisfactory, U=Unsatisfactory

S U Comments

Inspect bulkheads and skins for cracks

Inspect for delaminated skin/voids (Visually check. If

anomalies found, perform tap test See “Manual Tap Test”

on page 3-55.)

Inspect the security of all internal systems

Inspect windows/canopy for cracks and fit

Inspect canopy latching mechanism, hinges, and lock

Check that windshield and windows are bonded to frames

with no delaminations

Inspect rudder pedals and master cylinders for

security/leaks

Check rudder pedal adjust mechanism for correct

function.

(See “Inspect Rudder Pedal Rigging” on page 9-83.)

Inspect wing-to-fuselage root rib for cracks and

delaminations

Inspect systems and structure behind main bulkhead

access panel (fuse box, ECU, relay panel, landing gear,

water rudder actuator, and cables)

Inspect roll cable tension.

(See “Inspect Roll Cable Tension” on page 9-13.)

Check control sticks for freedom of movement

Check flap control operation and flap

actuator/bellcrank/cables

Check control cables, bellcranks and pulleys for corrosion,

attachment, and operation (See “Inspect Control Cables”

on page 9-8.)

Ensure the cockpit instruments are properly marked

Inspect DAC/MSC/instruments/lines for security and

condition

Loading...

Loading...