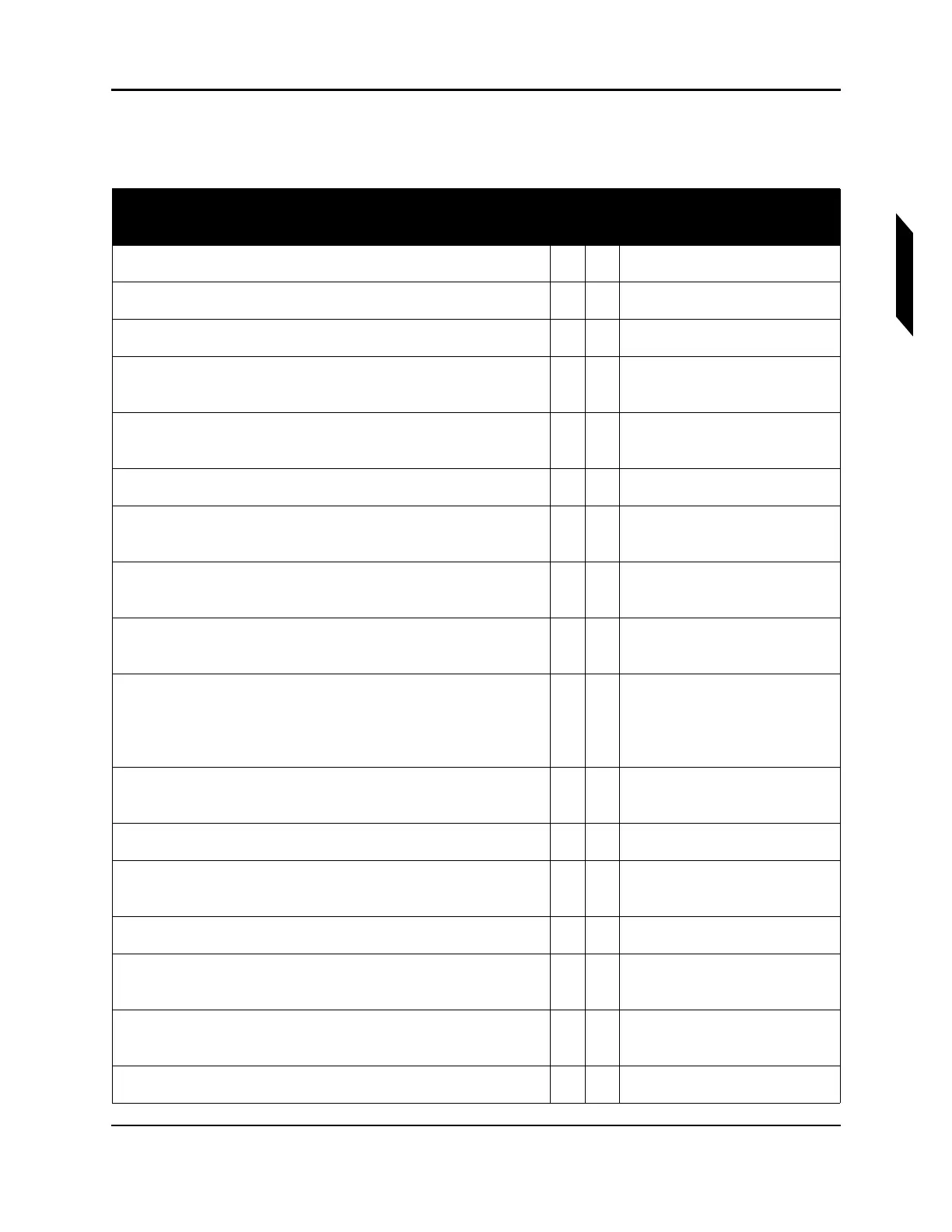

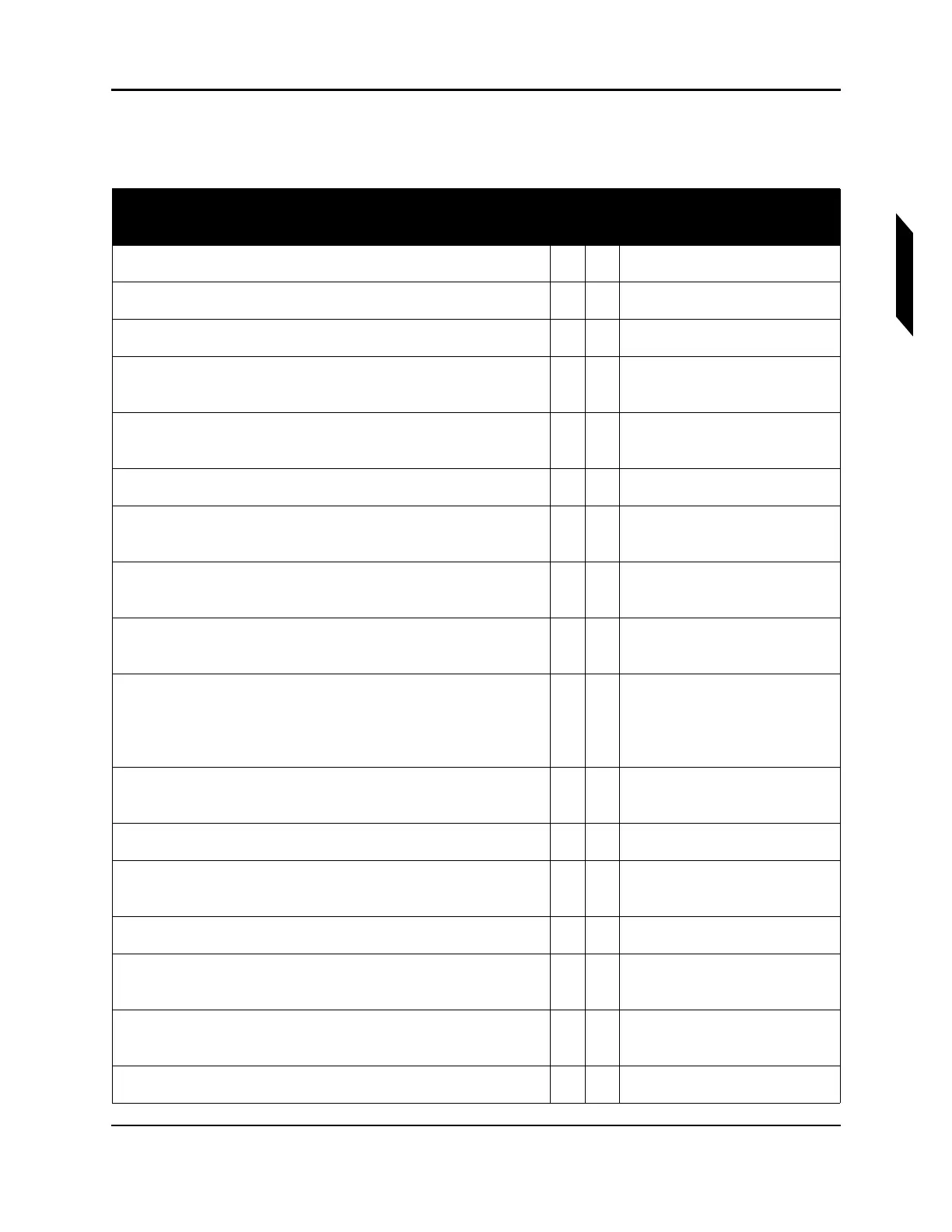

INSPECTIONS / CONDITION INSPECTIONS AND 100-HOUR INSPECTIONS 3-19

CHANGE C2 ICON A5 / MAINTENANCE MANUAL

3.3.7 Condition and 100-Hour Inspection—Aft Fuselage and Empennage

Correct all unsatisfactory items prior to flight

S=Satisfactory, U=Unsatisfactory

S U Comments

Remove two inspection panels and inspect seals

Check horizontal tail for security and condition

Check horizontal tail tips for security and condition

Check horizontal tail attach points for security, evidence of

motion, damage

Inspect outboard elevator and rudder attach points and

verify hardware is secure

Inspect hinges/rod ends for attachment and free play

Inspect empennage skin for damage/delaminations

Verify no lateral play on elevator

Inspect yaw cable tension

(See “Inspect Yaw Cable Tension” on page 9-80.)

Inspect pitch cable tension

(See “Inspect Pitch Cable Tension” on page 9-42.)

Inspect pitch trim system, mounting bracket, and linkage

for security, proper rigging, and wear

(See “Measure Pitch Trim Tab Wear” on page 9-63.)(See

“Inspect Pitch Trim Tab Rigging” on page 9-61.)

Inspect all control cables, hinges, pulleys, pushrods,

bellcranks

Check for corrosion

Inspect all control stops for condition and security and

proper rigging

Static ports clear

Inspect yaw rigging (See “Inspect Yaw Rigging” on page

9-85.)

Inspect pitch rigging (See “Inspect Pitch Rigging” on page

9-44.)

Reinstall tail access panels

Loading...

Loading...